I have a 4(?)” vise similar to those shown in the first reply. It gets used occasionally, but is not my favourite by any means.

My favourites are the type ll as marketed by Arc. I have two – the 70 and 90mm. Some don’t like them at all, of course – a bit like Marmite?🙂 The smaller one is generally fitted to my smaller mill, as that mill needs all the help it can get where the z axis is concerned.

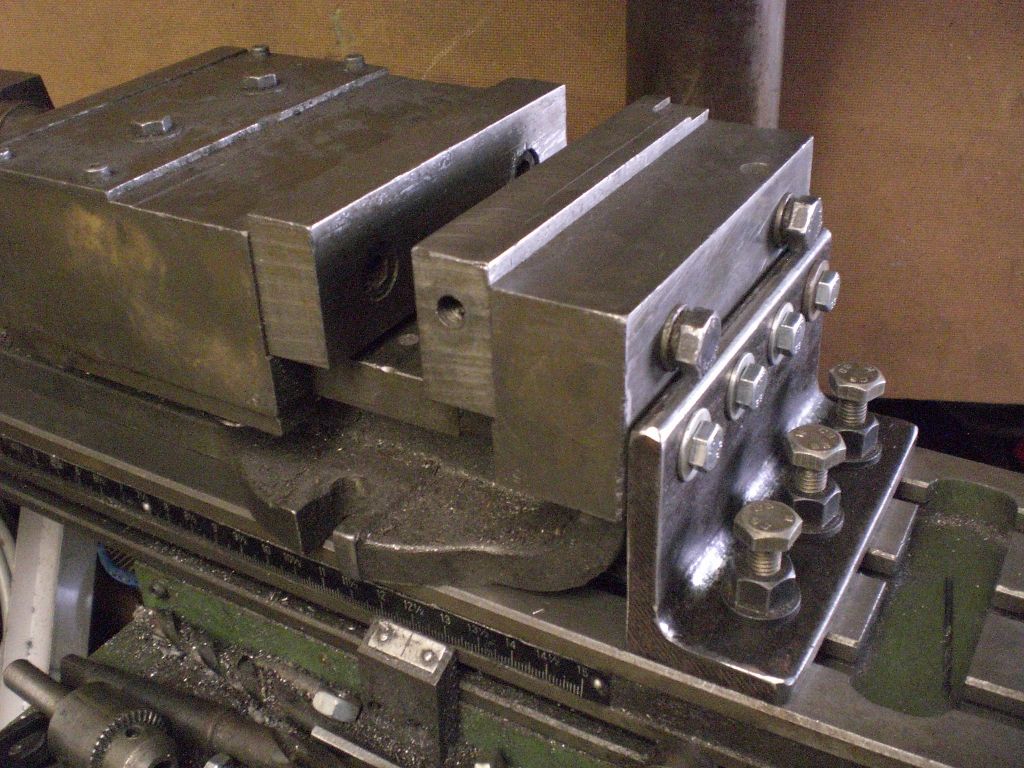

They do require more careful fixing to the bed and are not so simple to use (compared to simply winding a handle), but that does not bother me one iota.

There are other machine vises around the workshop. These include a smallish Abwood (about 80mm?), a tilting Abwood and an original Centec.

If I were to find other type ll vises (smaller or the 120mm) on an auction site, I might well make a bid if at the right price – as I have ‘borrowed’ the shallow vise from a Drummond shaper before now (on the Raglan).

One more possible advantage of the type ll may be that they can be mounted at a position of choice, rather than only at the nearest appropriate T-slot.

petro1head.

table (Y) and must be considerably taller.

table (Y) and must be considerably taller.