Whatever you do, steer clear of one of these, sold under various brand names. Mine was WoodStar.

With space issues. I searched widely and found that these had been converted to a table mounted saw by at least one respected member on another Forum. So, I got one. It comes as a portable saw with no mounting system for table use.

I went to considerable effort to fabricate the yellow and grey hinging mechanism seen in the photo which was problematic, added an auto cut-off switch, got good bimetal blades and was very pleased that I had a light portable saw. However, within a short while blade tracking became a problem. I added extra guides. Eventually the blade slipping off chewed up the wheel-bands and driving wheel and the saw became unusable.

Annoyingly 90% of the saw was reasonably well made but they had fitted PLASTIC wheels, which began to flex……..It was directly gear driven from the motor with one gear moulded into the plastic wheel so not easy to remedy. The ha'pworth of tar syndrome.

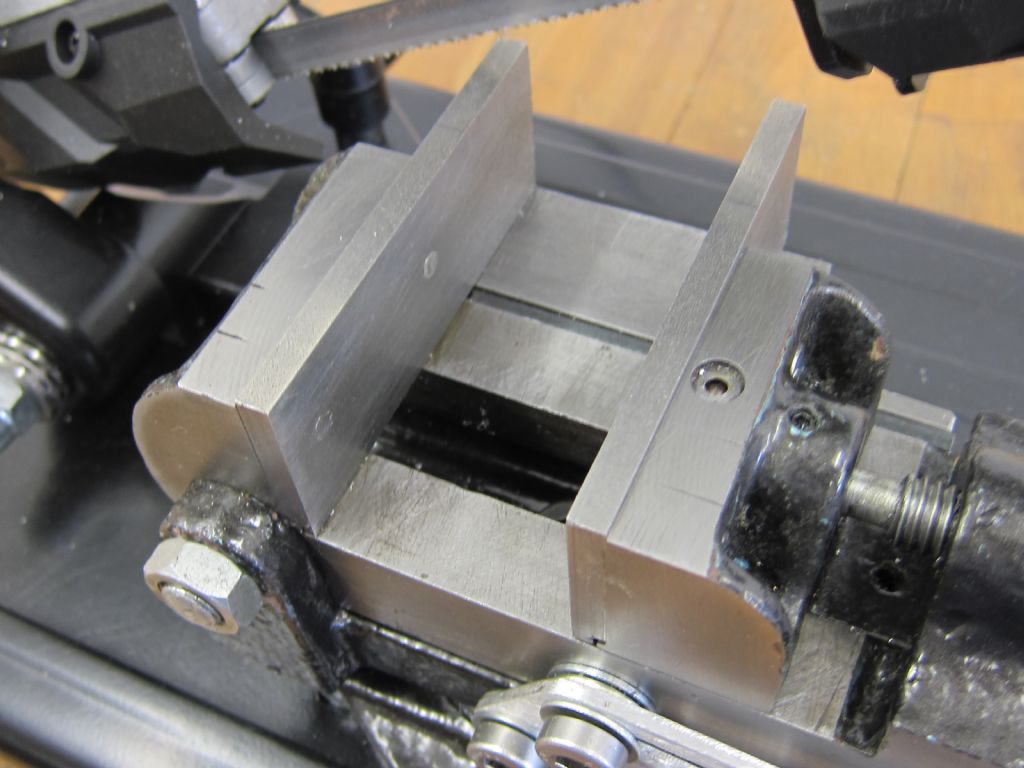

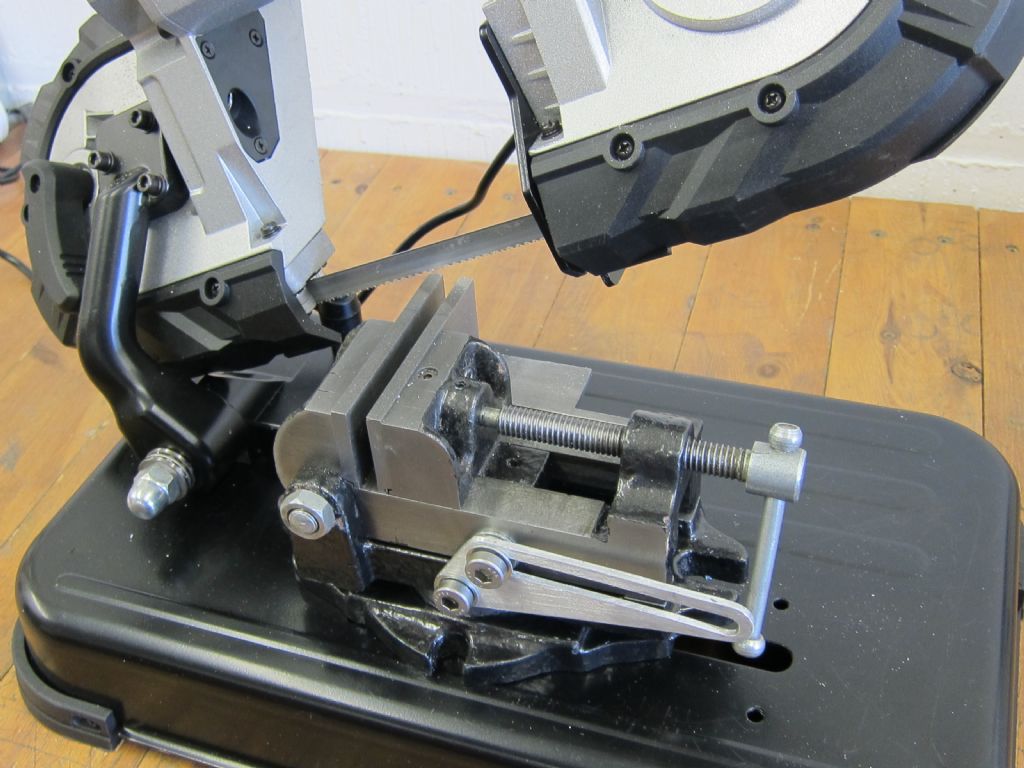

So you live and learn. I now have a second-hand Clarke model CBS45MD. I have done enough mods and fixes on it to write a whole chapter. It cuts straight and square in both planes and is a great addition to any workshop.

I hope my experience might save others from wasting their efforts on this type of machine.

John

Steviegtr.

Steviegtr.