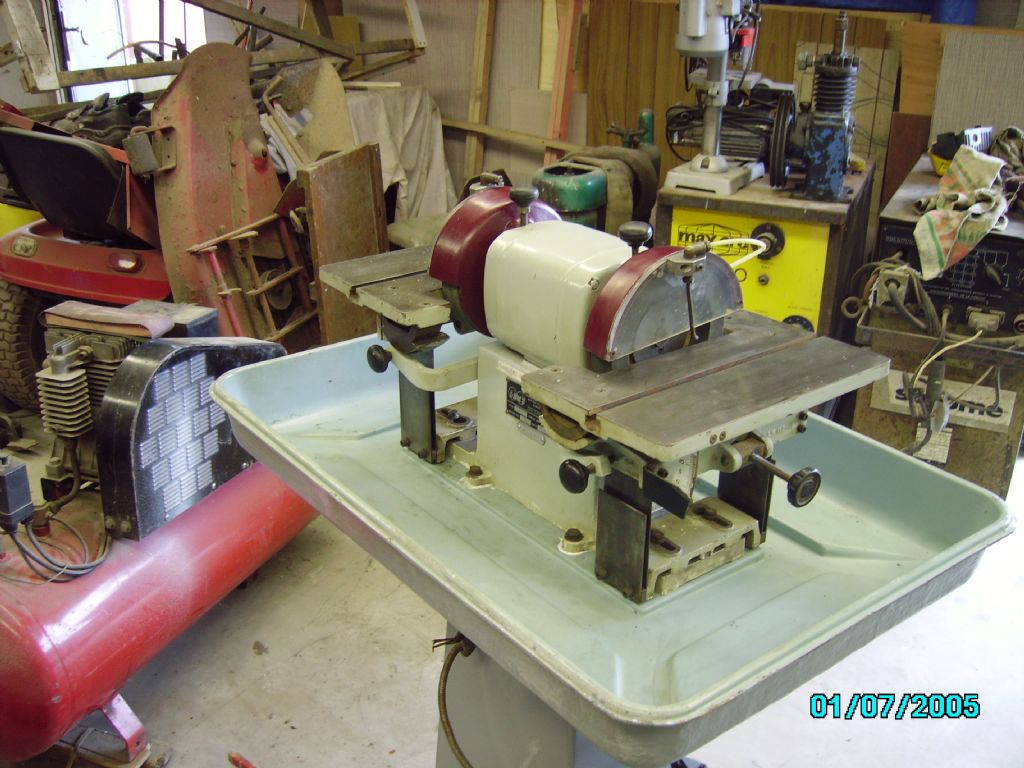

Masterlap double ended precision grinder, any info?

Masterlap double ended precision grinder, any info?

- This topic has 7 replies, 3 voices, and was last updated 20 June 2018 at 21:09 by

Phil Whitley.

Viewing 8 posts - 1 through 8 (of 8 total)

Viewing 8 posts - 1 through 8 (of 8 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issue

Newsletter Sign-up

Latest Replies

- Will iron rivets expand to fill oversized hole?

- Depth of cut cowells me90

- How many rings per piston?

- UK Steel Supplier? 125 x 125 x 50 BMS

- Bandsaw vs Powered Hacksaw vs Chop Saw?

- Ultra Newcomer Lathe Setup Query

- Meek style dog-clutch for a Colchester

- Chuck- Lathe yet another type.

- Pratt Bernard Grip true issues

- semiconductor help mosfets?

line up with two on the back (1" and 3/4) we could easily say" well thats where the electrics went, possibly with buttons on the front (or rods going right through) operating a NVR starter at the rear, but the coolant does not drain directly back into the column, but goes outside the column, at the rear, and then I assume back into the column via one of the four holes, perhaps after draining through a filter?, given the lengths of the original cables on both the pump and the grinding head, it does look like the electrics were on the back, and the cable from the head goes through the centre of the drip tray through a gland, into the column, and then out again. Some of the holes on the back appear to be threaded either 3/4 or 1" conduit thread. Prior experience has brought home to me the inadvisability of mixing three phase with water based cutting oils! The outlet from the drip tray has a hose barb on it, which suggests flexible pipe, but in the absence of any pics or info, I will play it by ear, though after all the crap I scraped out of the sump, a filter would seem like a good idea! I will post up more pics when it is back together.

line up with two on the back (1" and 3/4) we could easily say" well thats where the electrics went, possibly with buttons on the front (or rods going right through) operating a NVR starter at the rear, but the coolant does not drain directly back into the column, but goes outside the column, at the rear, and then I assume back into the column via one of the four holes, perhaps after draining through a filter?, given the lengths of the original cables on both the pump and the grinding head, it does look like the electrics were on the back, and the cable from the head goes through the centre of the drip tray through a gland, into the column, and then out again. Some of the holes on the back appear to be threaded either 3/4 or 1" conduit thread. Prior experience has brought home to me the inadvisability of mixing three phase with water based cutting oils! The outlet from the drip tray has a hose barb on it, which suggests flexible pipe, but in the absence of any pics or info, I will play it by ear, though after all the crap I scraped out of the sump, a filter would seem like a good idea! I will post up more pics when it is back together.