Out in the real world where folk simply need to cut a metric pitch on an imperial lathe the great advantage of the 127 gear is that it allows things to be done in an orderly fashion that can be simply tabulated. Mostly requiring only one gear to be changed for a useful range of threads.

The other effective tabulations using standard gears tend to hop around with the changes needed. Generally something of a pain. Rodericks table is about the neatest I've seen in that respect. Some versions are horrible.

Its all pretty moot if you have a screw-cutting gearbox. 127 is usually the only practical way of going about things. Especially as the folk who made the lathe usually provide you with a spiffy table of what to use when.

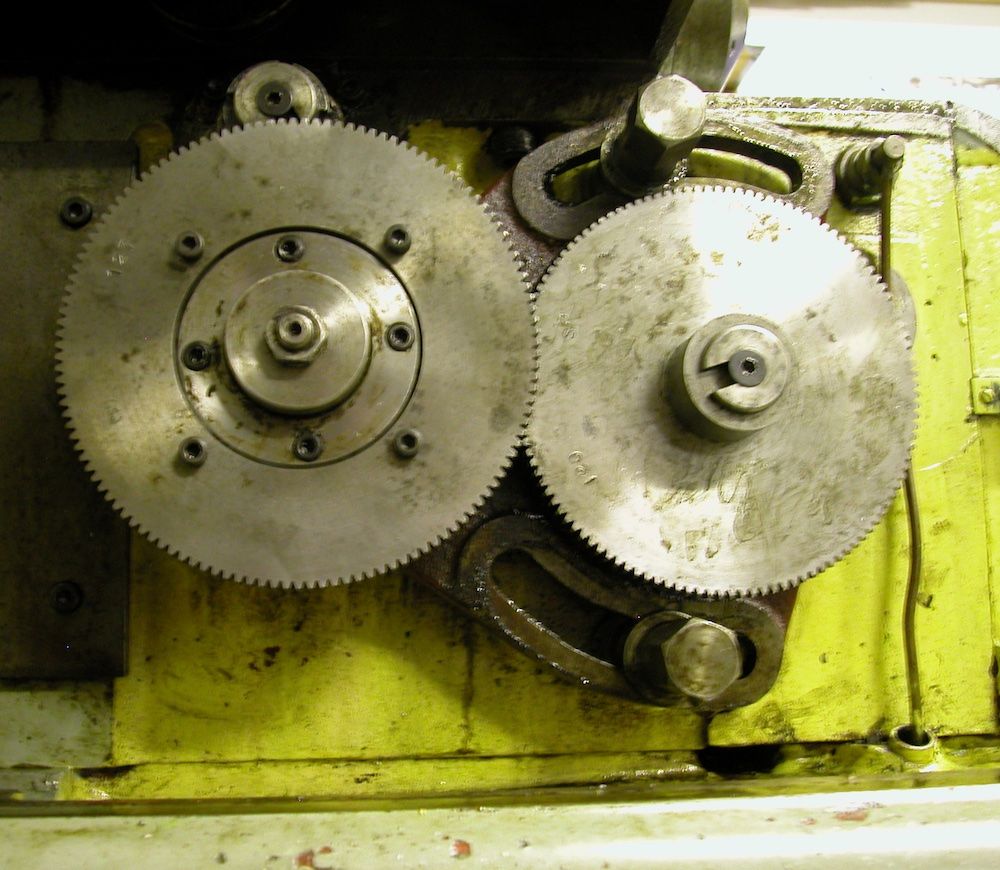

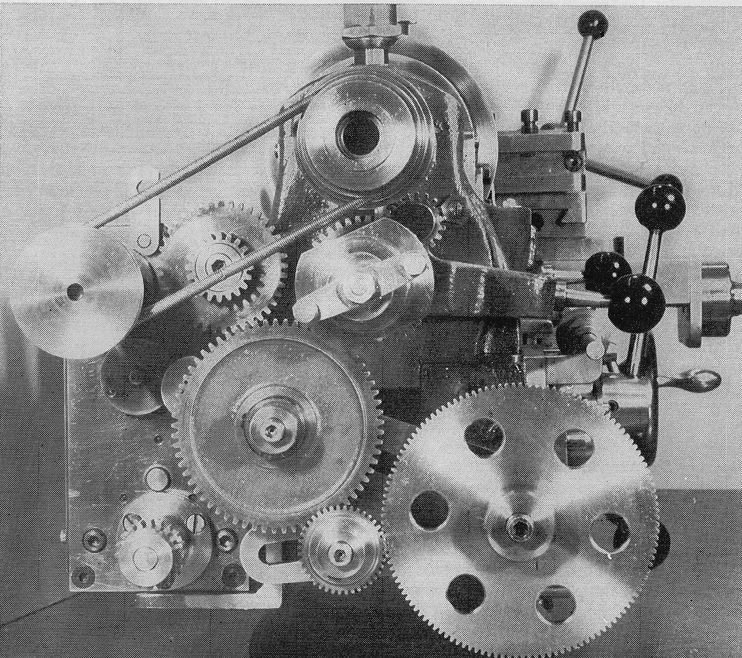

Generally the conversion set-up is the only compound gear train needed for the normal range of threads with most screwcutting gearboxes so its frequently practical to leave the 127 gear permanently mounted. My metric Smart & Brown 1024 has a nice roller bearing stud for the intermediate, 120 tooth, gear in the gearbox driving gear train. The metric to imperial conversion uses the 120 driven – 127 driver pair so it was asimple matter to bore out the 127 gear and bolt it on the outside of the 120 gear to align with the gearbox input gear in its conversion position. Changing from metric to imperial threading is now a simple matter of pulling off the spacer and standard 120 tooth gearbox input gear behind it then refitting the spacer followed by the appropriate gearbox input gear. A considerable improvement on the standard process which requires the banjo to be removed and the roller bearing stud replaced with a plain one before fitting the standard conversion gears.

This set-up has cost me 4 module pitches and, I think, 3 small BA pitches which worries me not at all.

I imagine something similar could usefull be devised for other machines.

Clive

Neil Wyatt.

Neil Wyatt.