Posted by SillyOldDuffer on 26/10/2016 19:35:13:

…

Noting that Iain unsuccessfully tried to shift the spindle with a home-made puller what's the best way of dealing of with this kind of 'jammed solid' problem?

Thanks,

Dave

Heat. Depending on the set up, you can heat the headstock housing to loosen the grip on the outer race of the bearing, or you can heat the inner race of the bearing to loosen the grip on the spindle.

You can use a propane torch to heat the headstock/race. Or you can use an electric heat gun available from any hardware store. Even a hair dryer will work, just takes a bit longer to get up to temp. Recommended temp is about 120C (250F). Roughly, hot enough that if you spit on the heated job, the spit sizzles and evaporates instantly.

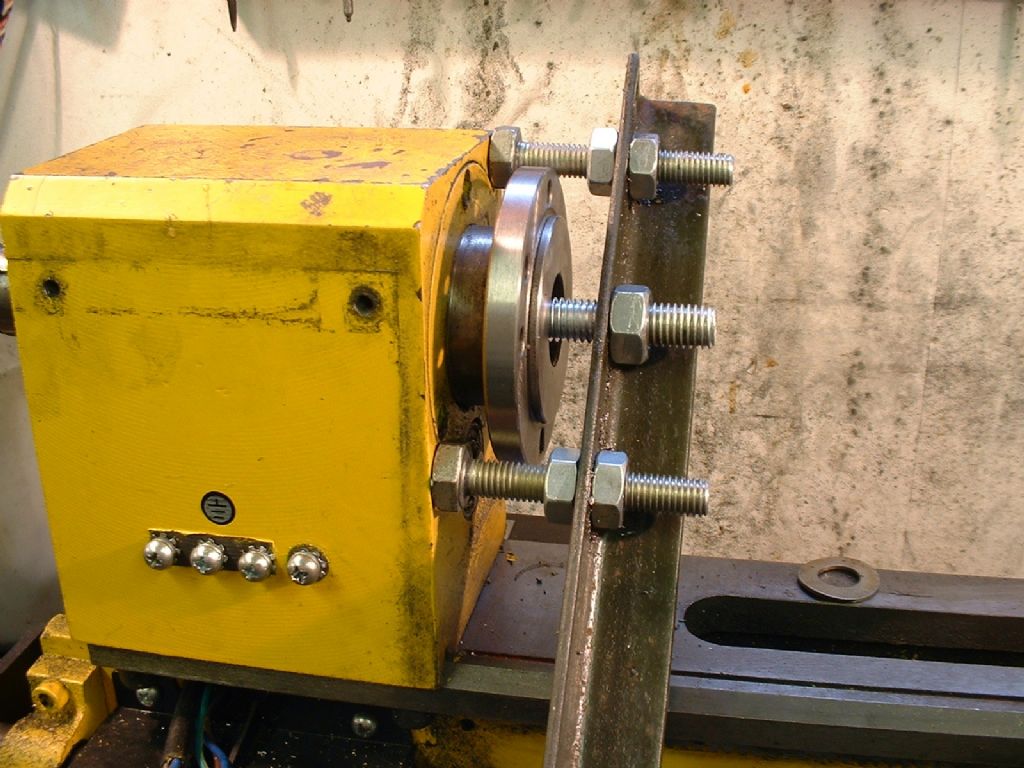

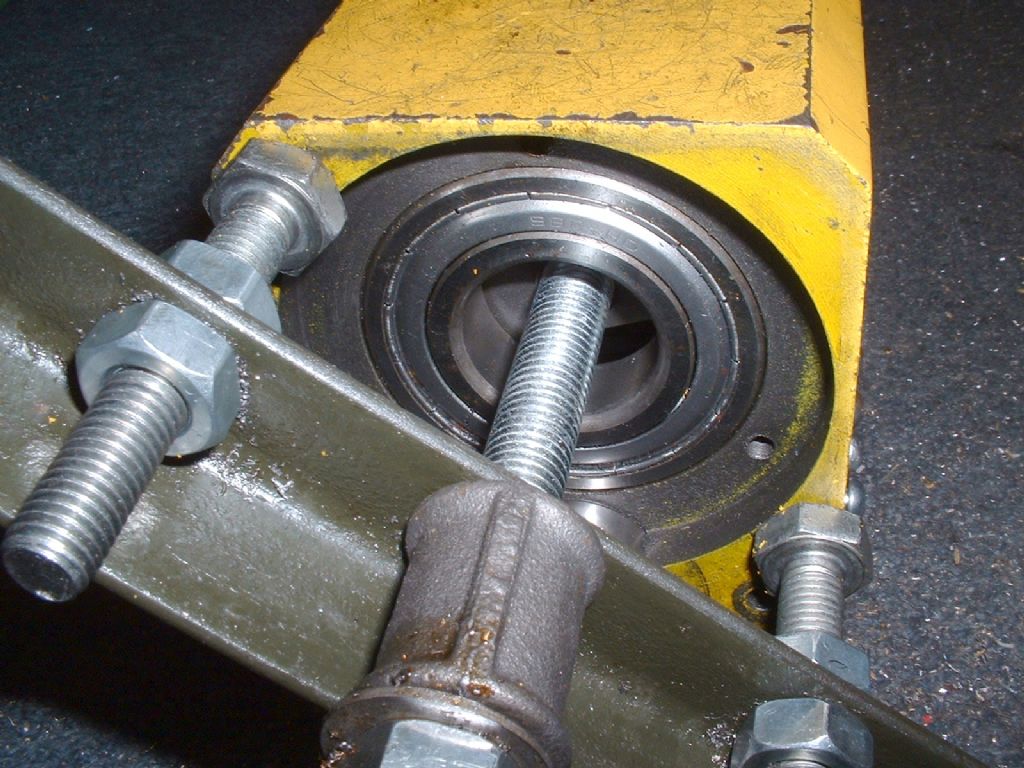

With a real sticky job, you can use a combination of methods. Put tension on the bearing/shaft with the puller as shown in the pics posted above, then if the bearing will not move, tap judiciously on the end of the spindle with a soft hammer or hammer and soft drift. (Be aware though that this destroys teh bearings and they should be replaced). Or, better option, put tension on the shaft/bearings with the puller and then heat the housing until the bearings move. If desperate, do all three, puller plus heat plus hammer persuasion.

On assembly, small bearings like these should be able to be installed on the shaft with light pressure from an arbor press, or from a piece of tube slid over teh spindle and tapped with a hammer so that all the impact is on the INNER RACE ONLY.

If the fit is too tight to do this, the spindle diameter needs measuring and emerying down slightly and carefully until the fit is right. Too tight a fit can expand the race — or indeed crush a thin walled hollow spindle — and adversely affect bearing clearance and life.

Likewise, bearings should tap easily into the housing on the OD. If not, burrs and maybe some metal need removing to get the right fit. Again emery tape or paper should do the job. We are usually only talking half a thou or so. And you can warm the housing, and even freeze the spindle and bearings overnight, to ease assembly, providing sizes are right.

Neil Wyatt.

Neil Wyatt.