The major problem with this endlessly repeated levelling debate is that folk focus on angles and level sensitivity rather than thinking in terms of whats actually happening and the amount of mechanical distortion involved.

The classic mantra is that if level is not maintained when bolting down the machine will be twisted causing error. The always ignored question is "How much error?". Actually its hard to screw things up enough to get a serious issue if the machine is fundamentally sound.

Frankly if you want to bolt a typical model engineers lightweight lathe down without inducing twist on a bench of uncertain flatness the best, easiest and fastest way is to arrange a stout, flat plate under the bolting faces at each end. Fix the plates to the bench and bolt the headstock end down. Shimming if need be so the tailstock end has a tiny bit of clearance. Shim under the tailstock feet to take up clearance plus an itsy bitsy teensy weensy bit more. Use a thin feeler gauge to judge the nip on both sides. Equal nip means equal force needed to pull the gauge out. Given smooth, lightly oiled, surfaces and a bit of mechanical sensitivity you can judge nip errors significantly less than 0.1 thou.

Which should be good enough.

This does assume that the manufacturer made the lathe accurately sitting on its own feet so that the bed is true when free standing. If the basic bed isn't true its time to weigh the machine in as it will never do good work.

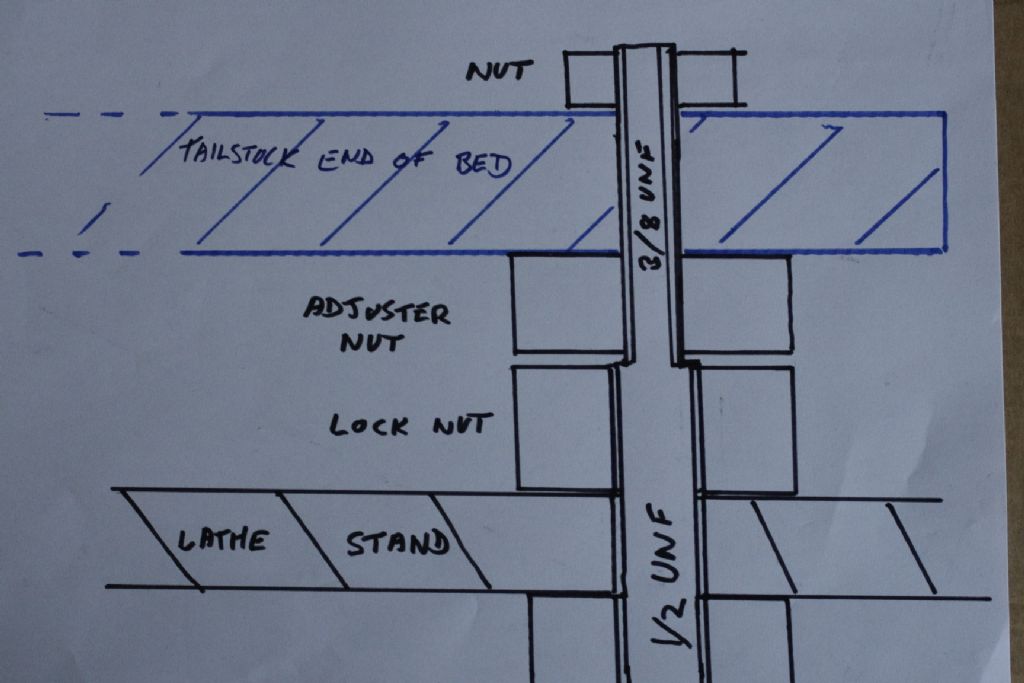

Feet base quality on most smaller machines is frequently un-wonderful so making flat face T section risers to sit in the feet helps matters. Proper screwed adjusters at the tailstock end make the job unbelievably easy.

Bench just needs to be level enough so stuff doesn't fall off.

Concerning sensitivity of levels in roundish numbers so imperial – metric aren't exact conversions :-

Typical builders level :- around 15 thou / foot, 1.25 mm / metre

"Carpenters" more precise version of the builders level for door frames et al around 10 thou / ft , 0.8 mm / metre

That cheapy from LiDL, big box DIY store et al will be worse! Even if it has a swanky laser.

Machinist level :- Typically 80 seconds of arc graduations, 5 thou / ft, 0.4 mm / metre

Master precision level :- Typically 10 seconds of arc graduations, 0.5 thou / ft, 0.04 mm / metre

The Starrett 199Z master precision level is 15 inches long with 7 graduations each side so about 5 thou tilt end for end will take the bubble off scale. Endless embuggeration if you don't have nice fine thread adjusters. The base isn't flat either. Its ground in a slight concave curve both ways to seat properly on a flat, really flat, surface. Visible line of light in the hollow.

The inexpensive import 0.02 mm per metre, 4 seconds of arc, nominal calibration levels probably aren't but they are so sensitive that repeated turning end for end is the only way to get any sort of result. Thats 1/4 thou per foot so if you buy the 8 inch one as being the largest you can fit on a small machine about 2 or 3 thou end for end tilt will take the bubble up to the end of the vial. Even building into a clinometer won't tame one of those. The baby 4 inch ones are an excellent candidate for arm launched satellite demonstrations.

I took time and care to get my Bridgeport table level to maybe 2 seconds of arc because a level table is ofttimes helpful when setting up. For non precision jobs slapping a level on is a lot quicker than running a dial gauge over it.

But for lathes pulling the shim between flat surfaces works fine.

Clive

Maurice Taylor.