LBSC’s Designs

LBSC’s Designs

Home › Forums › Locomotives › LBSC’s Designs

- This topic has 102 replies, 33 voices, and was last updated 18 March 2020 at 20:34 by

Michael Gilligan.

Michael Gilligan.

-

AuthorPosts

-

21 August 2017 at 01:57 #313110

Dean da Silva

Participant@deandasilva59410Having sat down and thought about this a little (I have been on night shift at work, my brain right now is running on coffee, cat naps and a shred of optimism) here's what I should have mentioned in my previous post I cannot edit for some reason:

Outcomes (from most likely to least likely)

1. 3D renderings on a website/in a forum while they are being completed

2. Archive of the original articles from which ever publication they came from made available

3. New design drafts made available

4. Publication into a book form of sorts- similar I would hope to the Kozo Hiraoka series of books, except where it would be a few of Curly's designs per book. This is what I would consider ideal, a hard bound series of this sorts. I'm not holding my breath though.

5. Some how a CNC mill and lathe combo mysteriously appear in my garage, and I am able to start building these wonderful models. I consider that so far fetched I wouldn't even count on that happening- ever.If you are interested in lending a hand in some way shape or form, please send me a message on here. If you have scanned some of Curly's articles and would like to send me copies digitally or magazines that has Curly's designs in them, that would be outstanding.

Regarding portions of the designs being out of date- I would rather draft that and have people omit it than omit it entirely. For example, in my situation here in the US, if I were to build something of Curly's which was generally updated in a better manner in the UK, chances are excellent I might not ever know because of either not knowing the design was that bad in the first place or the fact I live in Nearly Mexico (Yuma) Arizona.

If I had to chose only a certain gauge of models (or gauges) to draft again, it would likely be the models from 2 1/2" gauge on down. The larger gauges of models seem to be well preserved and have plans readily available, while the 2 1/2" gauge on down models do not seem to share that fortune- despite from what I can tell representing the bulk of Curly's work.

Once I have "LBSC His Life and Locomotives" in hand, I can really get a better idea of what I am up against.

On a lighter note, here's a Cracker.

21 August 2017 at 05:50 #313114

21 August 2017 at 05:50 #313114Niels Abildgaard

Participant@nielsabildgaard3371921 August 2017 at 07:37 #313115Marcus Bowman

Participant@marcusbowman28936I assume you know of LBSC's book 'Shop, Shed and Road'? It contains some photos of some of his designs. It does not contain build instructions for any complete locos, but it does deal with his standard fittings and approach to design and construction, including: injectors, pumps, gauges, whistles, safety valves, releif valves and snifting valves, motion work, lubricators, North-Eastern compounds and Mini-steam engines.

First published in 1929, the version I have is the 1969 version edited by the late Martin Evans.

There is also the book 'MONA: A simple 0-6-2 tank engine' by LBSC. That has drawings and build instructions for MONA in 3&1/2 and 1&1/4 inch versions.

The Gauge 1 Model Railway Association members are familiar with LBSC's gauge 1 designs

You may also be interested in the copyright position stated here:

http://www.john-tom.com/html/LBSCEngines.html

What would be of tremendous interest to me would be new sets of drawings, updated to reflect modern safety standards (boilers etc), and dimensioned primarily in metric units. If you want the designs to live on, that's the way to go, IMHO.

Your CAD approach is the right one, I think, especially as it would allow easy transfer of the drawings from CAD to CAM and CNC with little effort.

Marcus

21 August 2017 at 11:54 #313167duncan webster 1

Participant@duncanwebster1Posted by Marcus Bowman on 21/08/2017 07:37:22:What would be of tremendous interest to me would be new sets of drawings, updated to reflect modern safety standards (boilers etc), and dimensioned primarily in metric units. If you want the designs to live on, that's the way to go, IMHO.

Your CAD approach is the right one, I think, especially as it would allow easy transfer of the drawings from CAD to CAM and CNC with little effort.

Marcus

but Dean is from the USofA, that last bastion of Imperial measurements

Sorry, I'll take the dog out

21 August 2017 at 16:30 #313209

21 August 2017 at 16:30 #313209Dean da Silva

Participant@deandasilva59410l

Posted by duncan webster on 21/08/2017 11:54:35:

Posted by Marcus Bowman on 21/08/2017 07:37:22:What would be of tremendous interest to me would be new sets of drawings, updated to reflect modern safety standards (boilers etc), and dimensioned primarily in metric units. If you want the designs to live on, that's the way to go, IMHO.

Your CAD approach is the right one, I think, especially as it would allow easy transfer of the drawings from CAD to CAM and CNC with little effort.

Marcus

but Dean is from the USofA, that last bastion of Imperial measurements

Sorry, I'll take the dog out

That's alright sir, I've put them both out this morning. My male was a bit more stubborn than the female was. I don't think it would be TOO much of a problem to convert to metric, but I haven't the slightest idea on how the newer boiler designs would be done. Then again, I have a love hate with metric- it makes a lot more sense at times to use (especially concerning fasteners) but then at others I catch myself thinking "what the heck is this? Why can't XYZ in imperial have a nice round number in metric?!?"

I honestly am still scratching my head a little on how I am going to proceed with this. I'm hoping that maybe an established business in the U.K. in the world of model engineering would want to sell the designs- I really honestly don't care too terribly much about the money.

For what it's worth my machines are imperial. Curiously I own an American live steam pioneer's (Francis Moseley) personal milling machine. The same machine he invented the power feed for originally, as well as the DRO- the items the fine folks at Servo Products would go on to produce. Literally power feed number one that ever existed (the electric type that bolts to the table) was made on and for my milling machine in the previous owners hands. I joked once I only need Curly's Myford 7 and I'd have a machine tool museum.

If a club has a lot of the material for the models of a certain gauge (if not all) I'd do it for them no problem, I would actually love to see clubs maintaining this material to enjoy. If there are any typos in here I'm sorry, this was done on an iPhone.

21 August 2017 at 16:44 #313212Dean da Silva

Participant@deandasilva59410I've actually seen the 2 1/2" gauge association website before. The fact they have Curly's "Ayesha" from the boiler wars almost makes them the bearers of the holy grail- at least in the live steam context.

I'm curious how incomplete some of these drawings are- if by incomplete they mean it's the articles with out proper drafts (draughts? I need to put my computer's spell check on proper English) but it has the little bits from the magazine I'm sure I could manage. Granted, I might need drawings of the prototype or some input on finishing up the CAD files.

Being the perfectionist I am there is nothing that makes me more uneasy than having to guess at what I am drafting because the originals are missing dimensions. Especially with Curly's work. When I'm at my computer again I'll cite some examples that made me wonder a bit about his drafts.

21 August 2017 at 20:06 #313252Another JohnS

Participant@anotherjohnsDean;

Just a comment from a northern neighbour of yours. These are just thoughts, and the only arguing about them I'll do is in person over a pint of beer.

My Tich was built in inch measurements, but when moving about NZ and Europe, most everything was metric, as was a lathe I picked up while living in NL.

I converted, it was tough at the first, but became really easy.

Now, I convert inch plans to metric before machining, even if I'm doing CNC, as, for me, metric is just so much easier.

I'm surprised how Model Engineer has adopted metric, it's no where near 100%, but it was about 0% a decade or two ago.

Building metric in an inch country; most all of my materials now come in inch form, but a 1/2" round bar of brass I use as 12.7mm, etc, etc.

I can remember trying to buy a BA tap when living in NL, and I have the same issue back here. Metric is pretty universal; yes there are some thread pitch differences in older country-specific metric tables, but it is really as close to a world standard.

Kids know metric. In the USA, most of the fasteners on 3D printers are metric, as are the spools of filament. Cars are metric, etc, etc.

I'd love a little CNC Sherline lathe, but the one major item for me is that the fasteners are NOT metric, so it means yet another bunch of taps/dies/spare screws; like the Whitworth and BA screws on two of my British made machine tools, it is a hassle I don't want.

What you choose to do is TOTALLY up to you, and the inch (english, imperial, whatever you wish to call it) system works very well, but the world seems to be adopting metric, so your re-drawing to metric may prove to be more popular in the future, and maybe the "defacto" go-to for accurate LBSC drawings.

(BTW, should anyone complain, right now we have a partial solar eclipse going on, so, rather than fire back vitrol, just shake your head at the poor Canadian, and blame the "Eclipse Madness"

21 August 2017 at 20:32 #313262

21 August 2017 at 20:32 #313262 Roderick JenkinsParticipant@roderickjenkins93242Posted by Dean da Silva on 21/08/2017 16:44:52:

Roderick JenkinsParticipant@roderickjenkins93242Posted by Dean da Silva on 21/08/2017 16:44:52:I've actually seen the 2 1/2" gauge association website before. The fact they have Curly's "Ayesha" from the boiler wars almost makes them the bearers of the holy grail- at least in the live steam context.

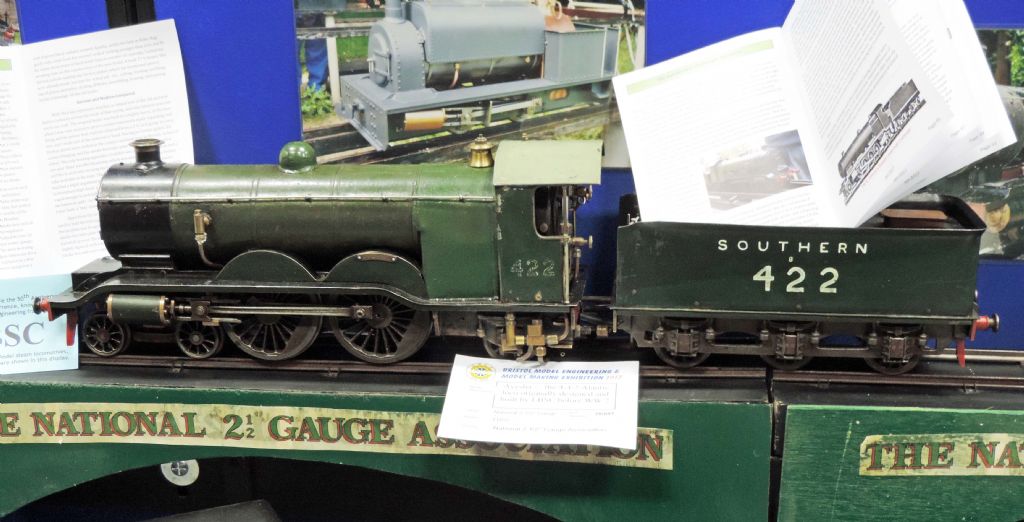

The 2 1/2" gauge association had Ayesha on show at The Bristol Model Engineering show last weekend. The show theme was the LBSC 50th anniversary:

More unusually, Greenly's rival Loco was also on show, on a different stand:

Cheers,

Rod

23 August 2017 at 05:11 #313473Dean da Silva

Participant@deandasilva59410Folks,

I'll have a post for you soon- a good long one. LBSC His Life and Locomotives arrived earlier than I hoped, and it's I think provided me with all the direction I needed for this project. I hope.

-Dean

Edited By Dean da Silva on 23/08/2017 05:12:08

23 August 2017 at 09:03 #313506 Russell EberhardtParticipant@russelleberhardt48058

Russell EberhardtParticipant@russelleberhardt48058Design rights are different to copyright. Copyright only covers the documentation of a design so should be no problem. Design rights in the UK are a recent thing see **LINK**

Russell

23 August 2017 at 09:32 #313515 Ady1Participant@ady1

Ady1Participant@ady1There's a UK copyright wiki here

24 August 2017 at 03:04 #313684Dean da Silva

Participant@deandasilva59410As promised, I'm back with a longer post- with more info.

Having had my mind warped from the tender age of 18 until I was 26 by the US military, here it is in the most… direct manner I can think of.

Positives:

1. A number of the designs are either rescaled versions of other designs, altered versions of other designs, or share parts with other designs, etc. Saves me time drafting!

2. Curly was NOT a rivet counter, or a spoke counter, or anything of the sort in a rubberized parka scrutinizing minutiae of a models realism. In a way, it would be almost the opposite of Curly to become wrapped around the axle about a set of wheels being exactly 100% prototypical and to scale. At least from what I can tell.

3. British locomotives are A LOT easier to draw in CAD. No bells, "cow catchers", big boxy head lights, super complex domes-just nice sleek, refined, elegance.

4. There is a LOT of variety in his locomotive line, the fact that he made a steam powered diesel in this era where I see electric powered steam engines is pure comedic gold, it's on par with two gentlemen in years past that lampooned diesel owners by putting a lawnmower on flanged wheels an running it around the Los Angeles Live Steamers club track.

5. So far, even if I have been doing little drafting and a lot of research on model steam engines, I am having a lot of fun at this!Negatives

1. I really don't like seeing vague drawings, or when I follow drawings the math doesn't quite come out right, case in point on the Dot, the radii for the pilot wheels at .75" at the location mentioned in the drawings left .985" between them instead of 1". While that seems little and silly, I am a perfectionist, and it DOES bother me.

2. There is no accounting for how many steam powered models he actually designed. Why do I say steam powered models rather than locomotives? I found a crane. A fire truck. A steam whistle. Only Curly and God knows what else I'll find.

3. A lot of locomotives have had their names changed, used different names, etc. Prime example: "A Six Year Old's 4F" is actually listed as "FIRS 245". I'm pretty sure that the Mona is going to be interesting, as I have heard of them existing in gauge 1, 2.5" gauge, and 3.5" gauge, and that Curly designed ANOTHER locomotive that was very similar to the Mona in many respects- which could have been relabeled as a Mona variant.

4. There are some of his locomotives (this is the worst of it) that really never were. Case in point, Hollywood Annie. I am frankly really nervous about trying to bring them to life, as I don't want to botch this project.

5. Did I mention that I am going to have to scour eBay for magazines that are as old as my grandmother and have them sent across the Atlantic to a place covered in sand dunes, tumbleweeds, and cacti?Now the fun part….

If you feel so inclined to scan copies of the articles, send copies of articles, send magazines that contain Curly's work in them which ever order I receive them in, I shall draft them in. I'll also be sure to dedicate the designs contributed to me to the people that contributed them to me, and hopefully find some way to repay the generosity extended in helping me with this massive undertaking. It would mean the world to me to finish this to the best of my ability for model engineers the world over to enjoy, and I cannot thank anyone who has lent a hand (even in the form of advise) to me enough.Thank you, I cannot express my gratitude enough, and if I tried writing it I'm afraid I would bore you.

Plus I am a terrible writer.For being willing to read my terrible writing, here is an exploded view of the Allen Models Chloe I did for fun.

24 August 2017 at 08:27 #313695

24 August 2017 at 08:27 #313695 JasonBModerator@jasonb

JasonBModerator@jasonbDean, can I ask what experience you have in building and designing steam locos? My reason for asking is that by adding in the bits LBSC left out, correcting errors, maybe converting to metric then testing them on a Solidworks model is one thing but you will in effect be drawing an untested design which may not work in the real world or be as efficient as it could be.

As an example there is another chap who has redrawn a lot of small engines and a few locos and traction engines in cad, converting to metric as he does so. It all goes together on his cad assemblies but in some cases what is drawn just cannot be built or has some very impractical sizes, missing or hard to work out dimensions, etc.

So unless an example has been built to this revised design how will anyone know it is going to work?

Regarding your comment about the detail on LBSC's designs they were built to be practical to run not display case replicas and it took someone with many years of designing engines to know what could be made to work in the smaller scales and what should be left out. Had he been making 7.25" locos then I'm sure he could have counted the rivits.

24 August 2017 at 10:15 #313706 Ady1Participant@ady1

Ady1Participant@ady1My 2cents would be

Do one CAD to completion and see what the pitfalls and issues are, instead of 26 at the same time

24 August 2017 at 11:37 #313713 Neil WyattModerator@neilwyatt

Neil WyattModerator@neilwyattDean,

Diane and I think the principle fo this is great and we would be happy for you to make 3D models of any designs we have the rights to and put something like interactive 3D PDFs or similar of them this website.

The problem is that it is proving almost impossible to identify which, if any, LBSC designs MTM still own the rights to; MyTimeMedia sold all its plans (except the Martin Evans plans, which MTM definitely own the rights for) to Traplet, Traplet have passed those on to Sarik Hobbies http://www.sarikhobbies.com/

There are also, of course, various designs Curly produced for other magazines than ME and associated Percival Marshal titles whose rights are (probably) owned elsewhere.

We think it would be best to avoid publishing full drawings in CAD format, but we could host CAD models here if:

- They were designs published in ME or English Mechanics.

- There's no sign of anyone else selling the design commercially.

- They go with a disclaimer saying that if anyone has the rights to the design let us know and if it they wish us to take it down we will do so as ASAP.

This does put the onus on you to do a bit of research on each design.

I hope that helps a bit.

Neil

24 August 2017 at 11:56 #313714 Russell EberhardtParticipant@russelleberhardt48058

Russell EberhardtParticipant@russelleberhardt48058Neil,

You are confusing design rights with copyright. The plans and the "words and music" are covered by copyright which lasts a long time. However the design rights for unregistered designs are relatively short term and any rights that LBSC had will have expired by now. So anyone is allowed to copy the design but not the documentation.

Surely a 3D model is just an electronic copy of the design. If drawings are created from that they are not the same as the original plans.

I think you are worrying too much.

Russell

24 August 2017 at 12:55 #313725Adrian Johnstone

Participant@adrianjohnstone89946I think the concept of design right does not apply to designs made before the introduction of the Copyright, Designs and Patents Act 1988 and I don't know if or what the equivalent rules were before then.

Adrian

24 August 2017 at 13:45 #313735 Neil WyattModerator@neilwyattPosted by Russell Eberhardt on 24/08/2017 11:56:23:

Neil WyattModerator@neilwyattPosted by Russell Eberhardt on 24/08/2017 11:56:23:Neil,

You are confusing design rights with copyright. The plans and the "words and music" are covered by copyright which lasts a long time. However the design rights for unregistered designs are relatively short term and any rights that LBSC had will have expired by now. So anyone is allowed to copy the design but not the documentation.

Surely a 3D model is just an electronic copy of the design. If drawings are created from that they are not the same as the original plans.

I think you are worrying too much.

Russell

Hello Russell,

Sorry I'm being sloppy.

Yes you are right unregistered designs have a 10-year lifetime, so people can freely adapt or use LBSC's designs.

It's the copyright in his plans which still exists.

You are probably right, assuming that any new digital version is a complete redrafting – tracing over a scan of the original plan would still be 'copying'.

Neil

24 August 2017 at 14:33 #313742 Ady1Participant@ady1

Ady1Participant@ady1That's my understanding.

A complete redraft will be owned by the person who drafted it.

The words bit in ME articles expire after 25 years

I also vaguely recall LBSC falling out with a photographer in the 1930s/40s over photographs of his work

Edited By Ady1 on 24/08/2017 14:37:18

24 August 2017 at 15:59 #313752Dean da Silva

Participant@deandasilva59410To a Posted by JasonB on 24/08/2017 08:27:23:

Dean, can I ask what experience you have in building and designing steam locos? My reason for asking is that by adding in the bits LBSC left out, correcting errors, maybe converting to metric then testing them on a Solidworks model is one thing but you will in effect be drawing an untested design which may not work in the real world or be as efficient as it could be.

As an example there is another chap who has redrawn a lot of small engines and a few locos and traction engines in cad, converting to metric as he does so. It all goes together on his cad assemblies but in some cases what is drawn just cannot be built or has some very impractical sizes, missing or hard to work out dimensions, etc.

So unless an example has been built to this revised design how will anyone know it is going to work?

Regarding your comment about the detail on LBSC's designs they were built to be practical to run not display case replicas and it took someone with many years of designing engines to know what could be made to work in the smaller scales and what should be left out. Had he been making 7.25" locos then I'm sure he could have counted the rivits.

Excellent questions, I'll try to do a better job at answering more of them as they are posted. Right now my drafting skills vastly outpace my skills as a machinist- and I am still saving my pennies if you will for the tooling to start on my first solo steam engine build. My first steam engine will be built with a client- we're also friends and decided to build a pair of steam engines which he designed. It's a monster- a 7.5" gauge, 2.5" scale early American 4-4-0. I prefer smaller scales though, and really only planned on doing that one and a mogul along the same lines with him. Again, another early American style locomotive. After that though, all British.

I think I know who you are talking about when you mentioned that other draftsman, if our brains are on the same wave I admire his work very much- but can see the potential for mistakes in it that might only be caught during the build process. I haven't designed a locomotive from the ground up- most of the work I have done comes from modellling parts for CNC/water jet production. I've done the full assemblies for the purposes of updating the drawings, catching maths errors in the drawings etc. Thus far, a good friend of mine who also works for my other client has checked over my work, which has all passed inspection with flying colors.

I do try my best to ensure the parts are designed so that they can be machined with out headache, are made from practical material sizes and given what ever diligence I can to ensure the designs I work with will work- and if not- not as a result of my error.

As far as actual drawings are concerned, I understand completely what you mean by missing or hard to work dimensions, some of the drafts for the Chloe and Fitchburg Northern had that same issue. The metric conversion could be an issue- Im not too concerned with it right now as much as I am simply tracking down the articles, I can't do a metric conversion with out a design to need it, and until I have that it can't even be attempted

I do believe I can find working examples of most, if not all, of Curly's designs. Knock on wood, fingers crossed on that one. Some of his designs are super easy, using oscillating cylinders and the like. I'll do the best I can to ensure the designs that I produce aren't stinkers- thankfully the client I am building the 4-4-0 with is a Curly fan too, has built more locomotives in 7.5" gauge than most people would build in a lifetime, and at 37 years old that's no small feat.

Short answer: I can't be 100% sure, but I won't feel comfortable with anything being put out or the like until I'm 99.9% sure.

24 August 2017 at 16:17 #313754Dean da Silva

Participant@deandasilva59410Posted by Neil Wyatt on 24/08/2017 13:45:06:Posted by Russell Eberhardt on 24/08/2017 11:56:23:Neil,

You are confusing design rights with copyright. The plans and the "words and music" are covered by copyright which lasts a long time. However the design rights for unregistered designs are relatively short term and any rights that LBSC had will have expired by now. So anyone is allowed to copy the design but not the documentation.

Surely a 3D model is just an electronic copy of the design. If drawings are created from that they are not the same as the original plans.

I think you are worrying too much.

Russell

Hello Russell,

Sorry I'm being sloppy.

Yes you are right unregistered designs have a 10-year lifetime, so people can freely adapt or use LBSC's designs.

It's the copyright in his plans which still exists.

You are probably right, assuming that any new digital version is a complete redrafting – tracing over a scan of the original plan would still be 'copying'.

Neil

Neil, your words are wise and eloquent. Writing to people in the U.K. always made me feel self conscious about my writing and my accent for some reason. (If I ever have the privilege of meeting anyone here in person, be warned, I do say y'all, use American euphemisms and stand an imposing 1.7 meters tall)

One idea I am toying with is just making 3D models of the designs that have drawings already- and hoping I could garner the support of a vendor, after all if this does capture people's attention it's free advertising*. For the models with out current drawings that's another matter, but it's just an idea.

*Granted, if they believe in the old saying "If it's for free it's for me!"

24 August 2017 at 16:19 #313756Dean da Silva

Participant@deandasilva59410Posted by Ady1 on 24/08/2017 14:33:12:That's my understanding.

A complete redraft will be owned by the person who drafted it.

The words bit in ME articles expire after 25 years

I also vaguely recall LBSC falling out with a photographer in the 1930s/40s over photographs of his work

Edited By Ady1 on 24/08/2017 14:37:18

I want clubs to have my work when it's done- granted the 2 1/2" Gauge Assocation would be the ones to receive all of Curly's work in that gauge, etc.

3 September 2017 at 19:04 #315059John Lluch

Participant@johnlluch21161Dean, I would also like to see LBSC designs drawn in 3D CAD and converted to metric. I am a metric system (the SI system to be more precise) guy, and I only learnt about the existence of something else (imperial) in recent years. I mean, I knew that an inch was 25.4 mm, but I never thought that this was something that was used in practice, specially on engineering plans. When I first ordered locomotive plans from Reeves, I became highly disappointed at learning that fact. So that's to make clear that I REALLY would like to have model engineering plans in mm units rather than something else.

Now, said that, I want to make the point that converting existing plans in inch units to mm is not as easy or straightforward as it might seem. Yes, it is of course just a matter of multiplying everything by 25.4, but the problem is that the imperial system is fractionary, not lineal. Dimensions in inches are often expressed with fractions, which means they are not actual exact measures, but just approximations.

The 3D CAD itself will essentially work because computer numerical precision goes up to at least 10 decimal places and therefore approximations may be good enough, but they will still be approximations, and accumulation errors may appear when adding dimensions, possibly causing trouble in assemblies.

The fractional nature of the inch system is problematic because you do not enter a fraction to a CNC lathe or CNC mill. Also a CAD-CAM program will not generate fractional output but numbers with a limited resolution (several decimal places).

Furthermore, plans that were originally drawn in inches will become really odd when translated to mm. To begin with, you will have to carefully round part dimensions to exact numbers in order for the CAD system to avoid accumulation errors. This is difficult, because it is easy to make a lot of assembly mistakes. If you chose to keep the parts dimensions as they are with all their decimal places, then you will either have very long numbers over the dimension lines, or they will appear rounded anyway, not reflexing the actual measures, thus causing further trouble.

Whatever approach you take, the converted dimensions will be bizarre, as opposed to simple and clean of newly drawn plans, making it evident that the original plans were in inches rather than millimetres.

The International System of Units (formerly metric) is exclusively used elsewhere except the UK and some USA. It's a superior system, which has greatly facilitated the latest developments in physics, and it is definitely the way to go.

Steam locomotives in continental Europe where all built in metric units, and model engineers there only use metric units for their models. But if you have some old British plans in an alternative system, then keep them as they are because attempting to do otherwise calls for a lot of trouble.

Edited By John Lluch on 03/09/2017 19:07:33

3 September 2017 at 19:07 #315061 Neil WyattModerator@neilwyattPosted by John Lluch on 03/09/2017 19:04:16:

Neil WyattModerator@neilwyattPosted by John Lluch on 03/09/2017 19:04:16:The International System of Units (formerly metric) is exclusively used elsewhere except the UK and some USA. It's a superior system, which has greatly facilitated the latest developments in physics, and it is definitely the way to go.

A brave man indeed. I'd fetch my tin hat if I were you John

I was just going to leave that comment, but I think I ought to respond to you claim that fractional dimensions are all 'approximations'. Not true at all.

It's also far easier to design things in fractions than using infernal metric preferred sizes. Add up a series of sizes in preferred metric sizes and they NEVER seem to come to a convenient number, fractions make it easy to design with good proportions and to achieve sensible cumulative sizes.

Try laying out a slide valve and its eccentric in fractions; it is dead easy as all the cumulative dimensions make sense, but you do need to have grown up using fractions

Neil

Edited By Neil Wyatt on 03/09/2017 19:13:32

3 September 2017 at 19:37 #315065HOWARDT

Participant@howardtHaving followed this thread from the beginning, it appears that most of the comments are about copyright which not being a lawyer I won't comment. My thought is perhaps more important. If it is the intention to keep the creations as CAD models and drawings, what format will be used. I worked as a designer all my life, and went to CAD in 1989. With changes to the core of the CAD systems old files become unreadable unless you convert immediately after the change. Also later minor changes make for incompatibility. The only sure way is to create jpg scans or similar, even PDF may not be an option. Just a thought, but been there and got the tee shirt on reading old files!

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › Locomotives › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Taylor Hobson cutter grinder modificaton

1

2

Started by:

David George 1

in: Workshop Tools and Tooling

David George 1

in: Workshop Tools and Tooling

- 9

- 38

-

22 August 2025 at 22:29

David George 1

David George 1

-

Material advice

Started by:

tobyonekenobi in: Materials

- 8

- 17

-

22 August 2025 at 22:19

tobyonekenobi

-

QCTP for chester lathe

Started by:

Chris12 in: Beginners questions

- 9

- 21

-

22 August 2025 at 22:06

dk0

-

Museum donation

Started by:

Stephen Wessel 1 in: Introduce Yourself – New members start here!

- 2

- 2

-

22 August 2025 at 20:36

Bazyle

Bazyle

-

Blackgates 3 Way Toolpost Casting

Started by:

John McCulla in: Materials

- 8

- 9

-

22 August 2025 at 20:12

Clive Foster

-

This weeks oddity!

Started by:

Martin King 2 in: Help and Assistance! (Offered or Wanted)

- 2

- 2

-

22 August 2025 at 19:12

bernard towers

-

Casting – off center hole correction

Started by:

colin hamilton in: Workshop Techniques

- 9

- 10

-

22 August 2025 at 17:38

colin hamilton

-

A4 stainless

Started by:

David Ambrose in: Materials

- 8

- 10

-

22 August 2025 at 17:37

Vic

Vic

-

Granville lathe leadscrew change wheel

Started by:

JACK SIDEBOTHAM in: Help and Assistance! (Offered or Wanted)

- 10

- 17

-

22 August 2025 at 17:07

Howard Lewis

-

wood working

Started by:

Danni Burns in: Beginners questions

- 9

- 12

-

22 August 2025 at 15:55

Danni Burns

-

3″ Castings – Help/Advice needed

Started by:

Andy Porter 1 in: Traction engines

- 4

- 6

-

22 August 2025 at 13:15

JasonB

JasonB

-

AI ads

Started by:

Ian Parkin in: The Tea Room

- 5

- 5

-

22 August 2025 at 13:00

jimmy b

jimmy b

-

1″ Minnie Traction Engine

Started by:

milburyring@btinternet.com in: Traction engines

- 3

- 8

-

22 August 2025 at 08:53

milburyring@btinternet.com

-

Solar panel

Started by:

duncan webster 1 in: Electronics in the Workshop

- 8

- 13

-

22 August 2025 at 07:19

Michael Gilligan

Michael Gilligan

-

The stand alone weight for tower clock

1

2

Started by:

dk0 in: Clocks and Scientific Instruments

- 12

- 36

-

21 August 2025 at 23:59

Clive Steer

-

Install & commission of a Chester Cub 630 (Warco GH750)

1

2

3

Started by:

Calum in: Manual machine tools

- 22

- 74

-

21 August 2025 at 21:52

noel shelley

-

Asong power feed?

Started by:

Hollowpoint in: General Questions

- 4

- 4

-

21 August 2025 at 21:43

andy198712

-

Softening epoxy

Started by:

John Haine in: General Questions

- 17

- 25

-

21 August 2025 at 18:57

Martin Dilly 2

-

What Did You Do Today 2025

1

2

…

9

10

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 35

- 226

-

21 August 2025 at 17:38

Dalboy

-

Denford Orac refit

Started by:

Richard Evans 2 in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 3

- 4

-

21 August 2025 at 14:56

Richard Evans 2

-

Phone Phreaking

Started by:

Michael Gilligan

in: Clocks and Scientific Instruments

Michael Gilligan

in: Clocks and Scientific Instruments

- 10

- 12

-

21 August 2025 at 12:48

Clive Steer

-

F360 stock from solid

Started by:

Roderick Jenkins

in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

Roderick Jenkins

in: CNC machines, Home builds, Conversions, ELS, automation, software, etc tools

- 9

- 16

-

21 August 2025 at 10:44

Roderick Jenkins

Roderick Jenkins

-

Harold Hall – 1933 -2024

Started by:

Neil Wyatt

in: Website Announcements

Neil Wyatt

in: Website Announcements

- 14

- 19

-

21 August 2025 at 00:07

Michael Gilligan

Michael Gilligan

-

Manual for Warco GH750 or Chester Cub 630

Started by:

Gavlar in: General Questions

- 7

- 16

-

20 August 2025 at 22:54

peagreenpete

-

Greatest Model Engineer

Started by:

Juddy in: The Tea Room

- 17

- 24

-

20 August 2025 at 21:41

Nigel Graham 2

-

Taylor Hobson cutter grinder modificaton

1

2

-