Been discussed here many times and there are various solutions from the simple (and cheap) – to the not so simple (and not always cheap). My machines are generally old (and not pristine) and so I guess I don't worry quite so much as someone who has paid a small fortune for them..However, I still try to take care of them

In 'Shed' terms – my situation sounds very similar to yours (unheated, uninsulated & slightly draughty) and I also suffer from rust if not careful – especially on a warm morning come the Springtime. I don't want to insulate (various reasons) and cannot afford to heat the Shed (or the machines themselves) either.

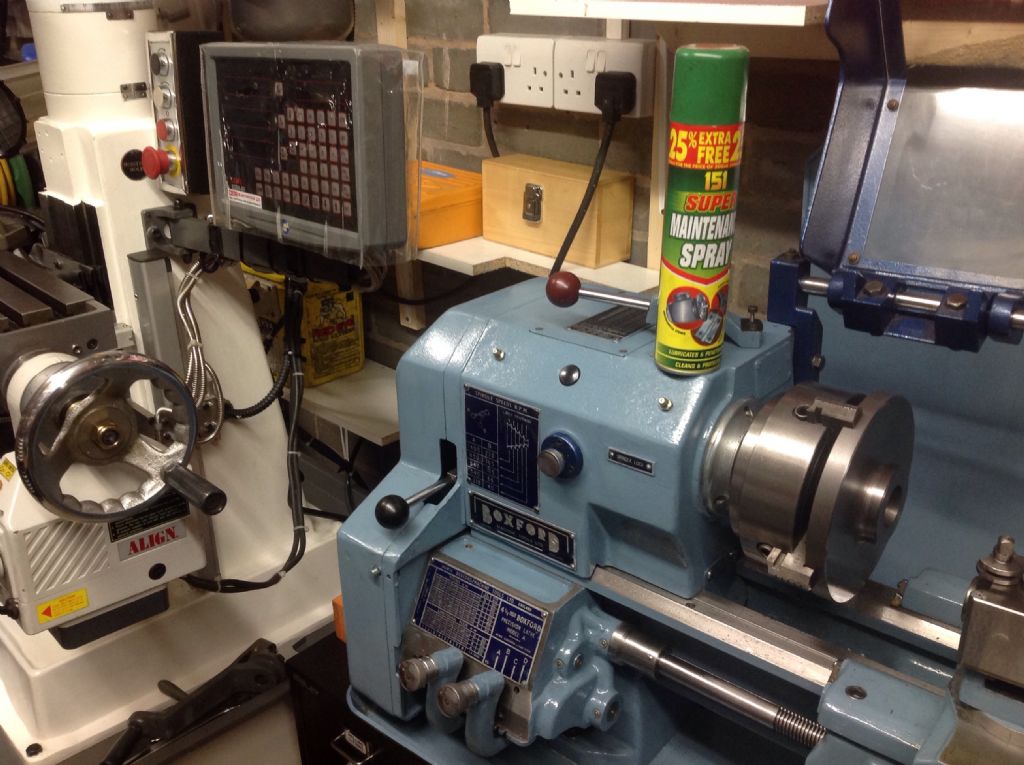

My solution is to wipe machinery over with an oily rag before and after use, paint any 'non-reference' surface and cover machines (lathe beds, milling tables, exposed metal generally) with a plastic sheet, topped off with an old blanket when not in use. I keep my best tooling indoors and anything else is usually kept wrapped in cling film (or plastic bags) and/or stored in recycled plastic biscuit boxes. Again – everything is kept well oiled.

It's not perfect but generally this works quite well (when compared to when I did none of the above). You may find a better solution eventually – but this will be a quick (and cheap) solution for now. It takes a little extra time and you have to get into the habit of doing it but it does make a difference.

As all my machines need oiling before use (and there's usually some to mop up – ever used a Myford Oil Gun?) – the oily rags tend to occur naturally but I guess any clean machine oil would do and in fact I purchased some "no-name" SAE30 recently (1 litre for about £2-£3 or so in Lidls) that seems perfectly usable and would be a good bit less expensive than WD40 over time and I suspect more effective.

Anyway – that's cheap and simple covered…

Regards,

IanT

pgk pgk.