If the Headstgock and Tailstock are not correctly aligned, turning between centres will produce a taper.

(Deliberately offsetting the Tailstock centre is used as a means of turning a taper )

If the Headstock is correctly aligned with the bed, work held in the chuck, but without Tailstock support should be turned parallell, AS LONG AS THE BED IS NOT TWISTED.

If the bed is twisted, the Headstock and Tailstock are unlikely to be correctly aligned at all points along the bed. They may be centre to centre at the Headstock end, but a twisted bed will mean that they move out of alignment as the separation increases.

If the bed is twisted, the position of the cutting tool will vary, in both planes, as the Saddle (Which you assume to be perfect ) progresses along the bed, to the detriment of parallelism and probably surface finish.

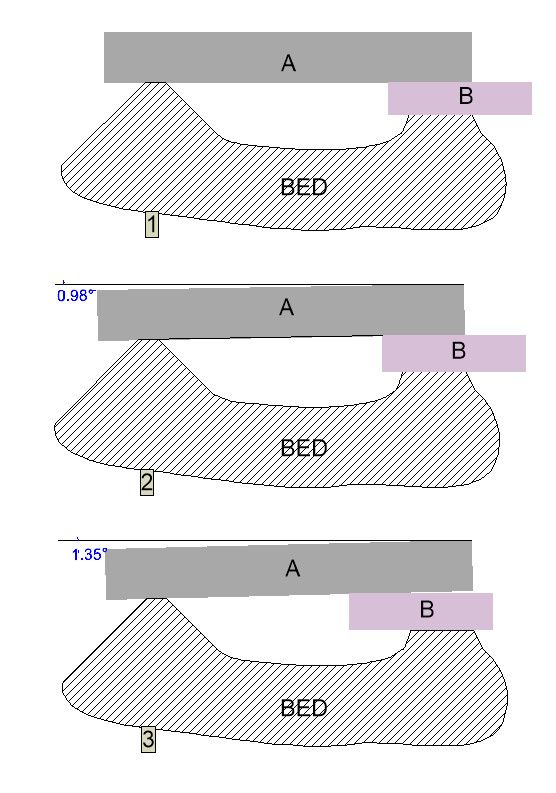

If (1 ) is at the Headstock end, and (3 ) at the Tailstock end of the bed, your illustrations make the point very nicely.

In particular, Myford, who started making lathes, originally based on the Drummond (dating from just after 1900 ) have only been making lathes for some 80 or 90 years, would not advise levelling the bed to eliminate twist, unless it was necessary.. They do not mention using the saddle as a datum.

It does not matter if the level, and its supports, resting on the bed, are not horizontal, as long as unworn sections are used for consistency, (Immediately beneath the chuck, and behind the Tailstock are unlikely to be worn )

What matters is that the level reading is the same at both ends, showing that the bed is not twisted.

Working off the Saddle introduces further possible sources of inaccuracy, and error.

Whether the bed is hogging or sagging is a different matter!.

Howard

old mart.

then fine, but rather unlikely. If it doesn't, then the horizontal position of block 'B' can have a noticeable effect on the orientation of 'A', as can be seen in the difference between diagrams '2' and '3'. Can you be certain of precisely positioning block 'B' for each measurement? I think not. But by using a purpose-made block (ie. the saddle), the uncertainty is completely eliminated.Once the best position of the level on the saddle has been found, then you just leave it there and wind the saddle along the ways to take the readings.

then fine, but rather unlikely. If it doesn't, then the horizontal position of block 'B' can have a noticeable effect on the orientation of 'A', as can be seen in the difference between diagrams '2' and '3'. Can you be certain of precisely positioning block 'B' for each measurement? I think not. But by using a purpose-made block (ie. the saddle), the uncertainty is completely eliminated.Once the best position of the level on the saddle has been found, then you just leave it there and wind the saddle along the ways to take the readings.