Posted by JasonB on 23/09/2015 07:21:45:

Hopefully our member with a hydralic attachment on his M300 will be along later.

Like now! As far as I am aware new hydraulic copy units are available, at least in theory, from India and possibly China. Hydraulic copy lathes seem to be more widely available, although primarily for the woodworking industry. The OP is correct that CNC has largely replaced hydraulic copy units for medium volume production.

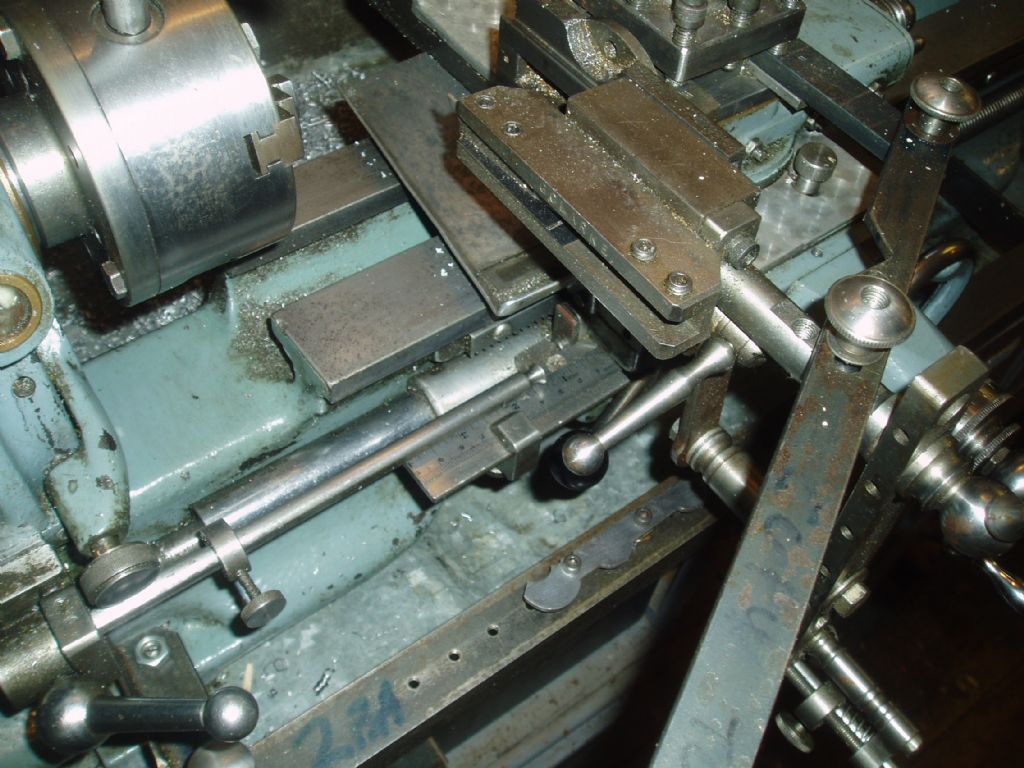

The units appear regularly on Fleabay, which is where I bought mine. Of course what lathe it is will run on is important. The units were designed for industrial lathes, so there's not much point in trying to run one on a mini lathe. Here is my unit in operation:

The (rusty) pattern and follower can just be seen bottom right.

My personal view is that small CNC lathes are not particularly useful; certainly compared to the smaller CNC mills. Once you get up to a sensible size, with the potential for live tooling, the cost has gone up a lot to.

Andrew

Nigel McBurney 1.