UThe lathe can't be reversed. As posted, it can. It is not needed as a normal procedure, other than cutting 'other'threads'.

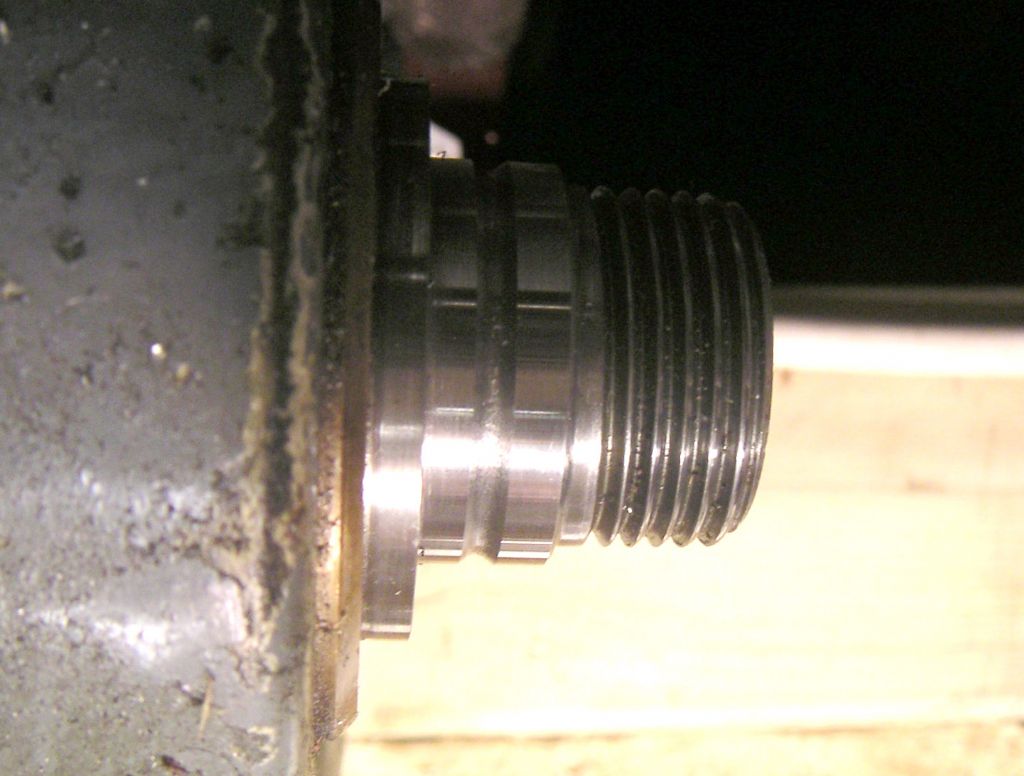

Over time a well used thread will wear. The back plate should wear, over a very long time. Worn threads are no real problem.

Presumably this increases run-out Wong assumption. It does not.

Any shock load, such as taking interrupted cuts, will tend to over-tighten the chuck

. True, but not normally a problem. They do not tighten on the threads, per se, only the register which is a flat face.

Threads damaged by rough use tend to wedge. Again, the threads are only there to screw on the chuck. The register is the important part.

Swarf in the thread could jam the chuck as will any corrosion. Swarf anywhere between mating surfaces will create a problem. Get used to it! No different than any other fixing method. It is only swarf on the registers that will cause damage.

Some oils exposed to air and warmth harden over time, with a risk that the chuck will eventually stick. An operator problem? Mineral oils recommended have been around for millions of years and have not oxidised. They are hydrocarbons which only react withoxygen at high temperature (ie they burn!). Simple enough to use the correct oil, I think.

Some people (like me) get their 'righty-tighty, lefty loosy' wrong, or like to tighten everything as hard as they can. There is no real answer to human disorders!

It's not unlikely that a combination of these problems could happen. It is unlikely if one simply follows the rules!

Finally, when releasing a stuck chuck, it's apparently very easy to damage the lathe. Once again, sometimes you can't teach some to do it properly. It is also easy to drop the chuck on the ways.

Often the chuck is only stuck after the lathe has been subjected to poor storage conditions. Not really the lathe's fault.

Other possible causes are fitting the chuck while at a considerably different temperature to the spindle. On a similar comparison, would you suggest that any morse taper fitting is unsuitable for use?

Yes, economics does play a part. Most of these lathes were manufactured when screw-on chucks were perfectly adequate for purpose, yet were economical. They also worked. Alternative fixing methods were considerably more expensive, not just a little bit.

Advantages are that they are far quicker to change than bolted chucks which may wear the spigot over time. They also work just as well. No problem of getting the chuck off a spigot, like some have experienced. Loose spigots are useless for minimising run out.

I would prefer a cam lock or L100 type, but the spin on chuck works just as well at a price which was affordable when new. Not many run around in a Rolls Roce or Bentley. There are usually adequate alternatives, without spending a fortune.

What arrangement do you have on your lathe(s)? Of the choice between bolted spigot and screw on, it is a easy choice for me. Screw on every time (I have had/used both types).

Edit: Sorry about the paragraph, or rather lack of. Out of my control. Forum has its drawbacks when trying to post!

Edited By not done it yet on 18/04/2017 16:05:14

SillyOldDuffer.