The increase in versatility that the draw bar gave was soon realised but the mill had one big short coming in that it was too short! That cast iron base it sat on was very substantial but far too low. The cross slide handle was at mid thigh level and I’m not tall!

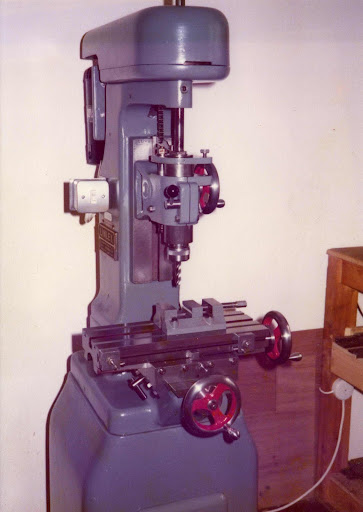

At some stage a decision was made to move it to a welded steel bench previously made and incorporate a drip tray too. At the same time I decided to strip it again and replace the bearings in the headstock. This time the paint was stripped off to the bare metal and repainted with some twenty coats of primer – one in the morn, one at night – house had the faint whiff of cellulose for a few days! Two coats of polyurethane grey top coat gave a finish that, the odd chip aside lasts to this day.

When that new Bridgeport arrived in 1986 I had to ask, well you would wouldn’t you?. So a pattern was made and a new table and handwheel bracket cast at the local founders – now gone and sadly missed. After taking the skin off it sat outside for well over six months before a succession of Friday afternoons saw it milled. A leadscrew was cut too and a new nut made but it would be well into the late nineties before it was finally fitted.

I found this photo today – it shows the small table still in use and the part is off the

BR2 which was worked on from ’92 -’96 – I think the table was finally changed around 98-99. It’s also now in the outside workshop. As you can see that table really is quite small. Also note this is pre modification to the R/T. Completely jury rigged stops using clamps but it worked.

The new table was made in proportion to the saddle roughly the same as the Bridgeport

and gave a 24″ table with 16″ of travel. The original leadscrew is still on the saddle and has 6 thou of backlash which is not bad for something well over half a century old.

An Ortec DRO was fitted about 2002 and this latest improvement in fitting a VSD brings it nearly but not quite to staisfaction – A DRO is required for the quill and I reallymust replace that old bolt with a neat handle on the down feed stop bar.

Here are some pics of what it’s current state is

As said elsewhere the new motor is of Italian manufacture. Very quiet, very smooth and extremely well priced.

So after some thirty odd years I’m nearly there with this mill and that really is why I decided to post this. Over those years it has served me well and it’s limitations have been stretched to some pretty alarming distances.

For the newcomer to the hobby there is far more available to you now than ever there was when I set out and particularly on the milling side. Putting aside the question of quality there is a vast amount of kit to tempt you but unless you have limitless resources then a steady plod will get you there – if not quite as slow as this one

.

Regards – Ramon

Edited By Ramon Wilson on 23/02/2011 21:36:37

Steve Garnett.

So he brought it out to the rig as baggage and I brought it back the same way – I can still see it now wrapped in sacking rolling down the carousel at Heathrow – Cor Bet you’d get away with that now eh!

So he brought it out to the rig as baggage and I brought it back the same way – I can still see it now wrapped in sacking rolling down the carousel at Heathrow – Cor Bet you’d get away with that now eh!