How to stay in control of mill depth of cut? (My mill has no fine quill feed)

How to stay in control of mill depth of cut? (My mill has no fine quill feed)

- This topic has 45 replies, 16 voices, and was last updated 5 April 2013 at 23:29 by

ray jones 1.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

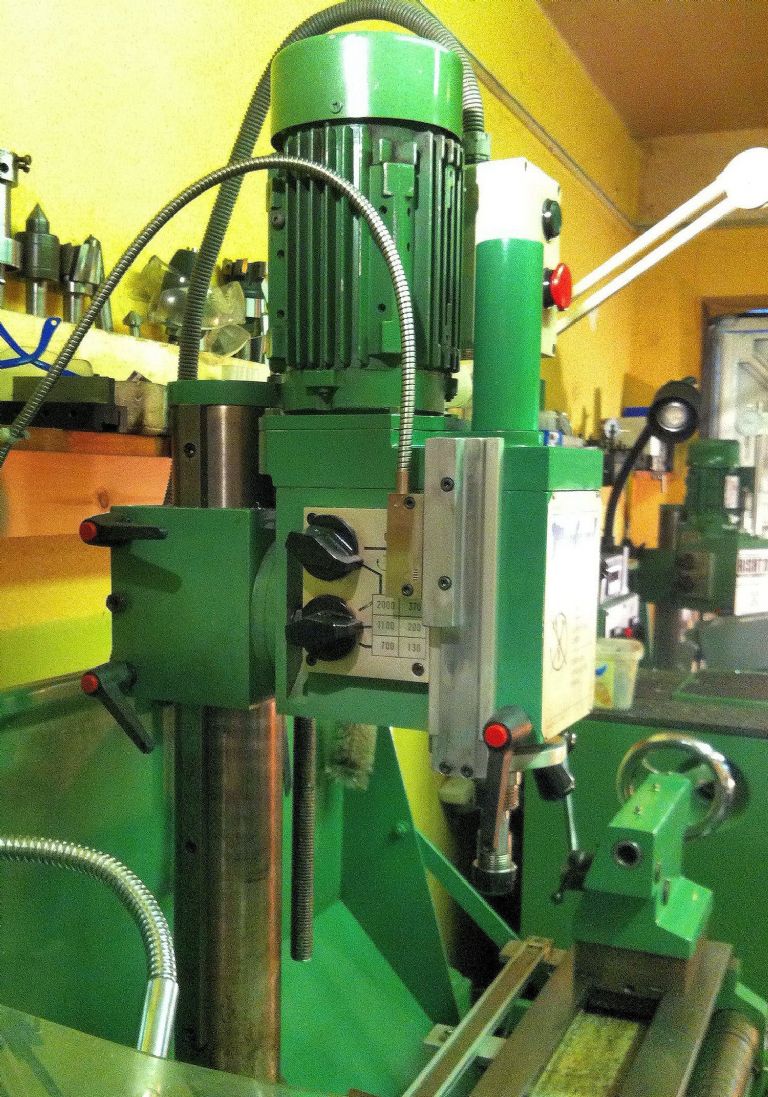

There are small differences but my HM-10 looks very much like that in the manual. by Grizzly Thanks.

There are small differences but my HM-10 looks very much like that in the manual. by Grizzly Thanks.