Posted by Hopper on 18/01/2020 01:46:20:

Stick with your standard toolpost until you learn a bit more about using your lathe.

+1 to that. But Stevie, please slow down. Nothing wrong with what you're trying to do but lack of experience is taking you deep into advanced territory. Too many difficulties – Here be Dragons. Dozens of em'

Not a good idea for inexperienced beginners to start with an unfamiliar lathe by stripping it down or making major modifications. Far too easy to do more damage than good, turning a decent machine into a botched dog.

I too am a "Clever Twit", with a successful engineering career behind me. I have every reason to be confident in my own field. But that level of confidence is absolutely not justified in Model Engineering / Home Machining because skill, judgement, timing and familiarity with processes and materials are more important than the theory. Practical skills and knowledge both matter. Although much of what I learned in my day job is relevant, it hasn't allowed me to short-circuit the learning process. For example, although a lathe is a simple beast in theory, getting consistently good results out of one has to be studied and practised, which takes time and effort. Good to have an expert on call – self-teaching slows the process down.

Putting it another way, I've driven a car for about 40 years without causing an accident. I'm some sort of 'Good Driver'. Doesn't mean I can safely jump on a powerful motorbike and expect to win races.

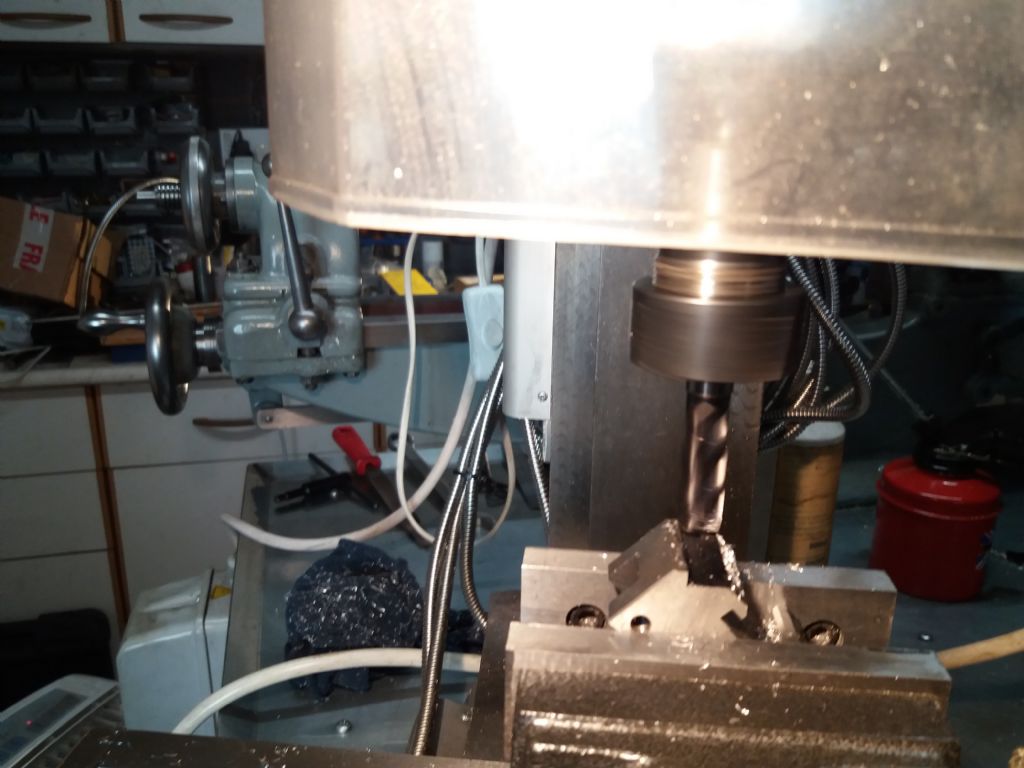

My advice is to start by tackling several straightforward projects like simple tools, and then progress to a simple model mill engine (my favourite is Stewart Hart's PottyMill). Not because I want one, but because the Plans are accurate (can you read an engineering plan?), it's pitched at just the right level of difficulty to challenge a beginner without leaving him in the dust, and getting it to run requires accurate measurement, reasonable finish on a number of different parts in Aluminium, Steel and Brass, fettling and assembly, clearing faults and reducing friction, and then adjusting the valve gear. Making one will teach many lessons about your lathe and its Operator's shortcomings. One lesson learned will be that – for many home projects – you don't need a QCTP. It will also highlight what's good and bad about all the tools used, such as why a Milling Machine is so highly desirable. Knowing from experience what needs attention on a lathe or elsewhere in the workshop is much better than guessing. Spend a year or two using the lathe before deciding if a QTCP is worth fitting. Then tackle the awkward problems caused by wanting to machine a hardened tool-post! It might be easier to cut your losses…

Dave

Edited By SillyOldDuffer on 18/01/2020 10:37:06

Steviegtr.

Steviegtr.

so I'm sulking.

so I'm sulking.