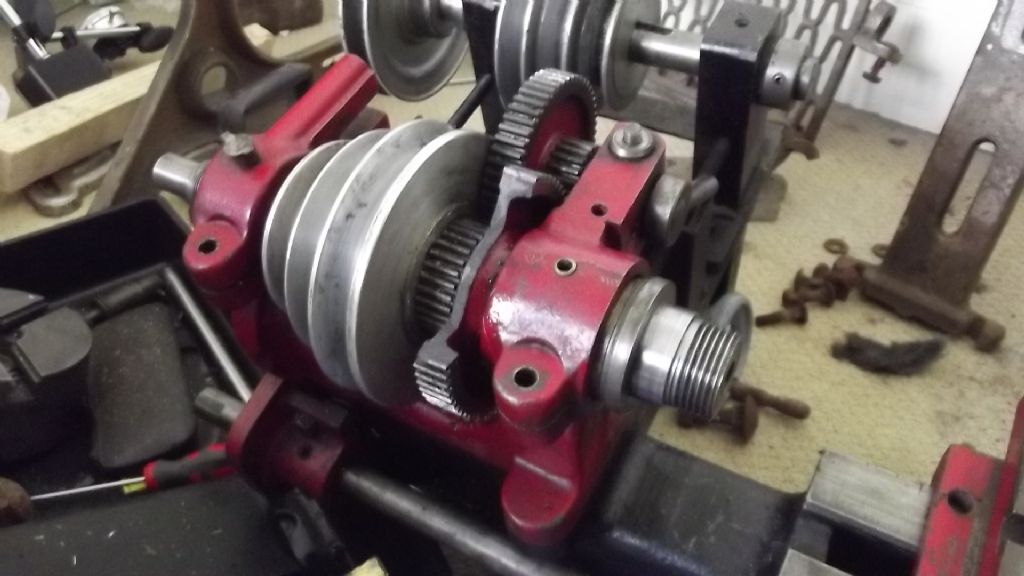

If it went one way and then stuck I would look very carefully for more grub screws. There will be something that allows the back gear to work – when that's in the pulley spins freely on the spindle and the drive is through the gears so the gear on the spindle will be located on the spindle some how. There will be a grubs screw or something or the other locking the pulley to the spindle for when the back gear isn't in use.

So for instance they might key the gear to the spindle and have a slot through the pulley and it's gear (Usually one piece some how) to allow it to be part knocked out that way to allow the gear and it's key to be removed. (Remember that if you ever do get a Pulta – something has to be aligned to get the spindle out. They provide marks )

From comments elsewhere I suspect the grub screw in the pulley is just used to lock it to the spindle. The way the gear right next to the pulley and effectively part of it is attached varies but it's probably a steel sleeve to provide a bearing for when the back gear is in and the spindle runs at a different speed. Might even be bronze.

RDG do some awful cheap black link belting on ebay – even when set really tight it will slip and stretch and stretch and stretch but does sort it's self out apart from slipping but I doubt if 1/2 hp can be fed through with it.

John

–

Rainbows.

Ebay seems to be catching up fast.

Ebay seems to be catching up fast.