Fools go where angels fear to tread, but it's never stopped me before!

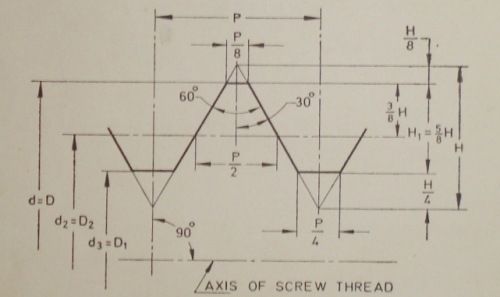

The form of a metric thread, and relative dimensions, are defined whether or not the diameter is a preferred size or not. Details in Machinery's Handbook, and similar tomes. I pinched this chart off the web:

Internal Thread at top, external thread below. For all metric threads H = 0.866 × pitch. It's usual for metric threads to be cut or rolled rounded at top and bottom rather than sharp as shown in the diagram.

Thread tolerances are somewhat complicated, ranging from very tight to downright slack, such as threads that are going to be plated. More info on Tolerance Positions and Tolerance Grades here, but I don't think Joe need read it!

A thread made as shown in the diagram would be an uncomfortably tight fit, hard to assemble, and any error in it's manufacture would cause it to jamb. Force fits aren't acceptable if the joint is meant to be unscrewed, so practical threads are cut with slightly oversized 'V's, in effect broadening the bold line. The difference can be seen by comparing DIY store zinc-plated studding with the same sized thread on an Allen Bolt. Studding is crudely made and slack; the Allan Bolt should be much cleaner, well formed and tight fitting in it's socket.

I think Joe can control how tight his thread fit is simply by cutting less deeply than normal. Cutting less than 0.866 × pitch will create an over tight thread, exactly 0.866 × pitch will fit with difficulty, and cutting deeper than 0.866 × pitch will create an increasingly slack fit. I'd make the internal thread first getting as close to 0.866 × pitch as I can measure (not sure how I would do that!), and then use the internal thread as a gauge to make the external thread a tight fit. Could be very tight, needing a strap wrench, or hand tight, as required.

EN8 may not be a good choice because a smooth surface finish is vital for a tight thread fit intended to be screwed and unscrewed, and EN8 often tears roughly when cut.

A precision collar preventing slop might be an alternative to hard to make precision threads.

Dave

Ady1.

Ady1.