Fine project there!

I've been pressing on withy my Hemingway kit too – the 'Worden' tool & cutter grinder.

I did drop two, related clangers , luckily recoverable.

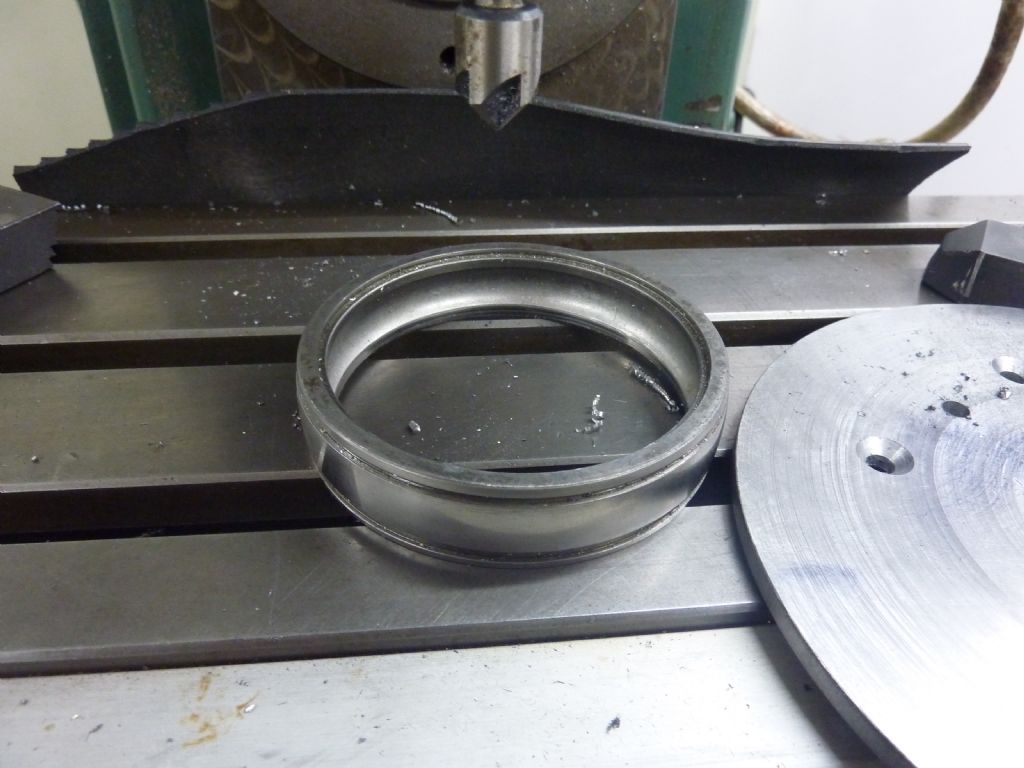

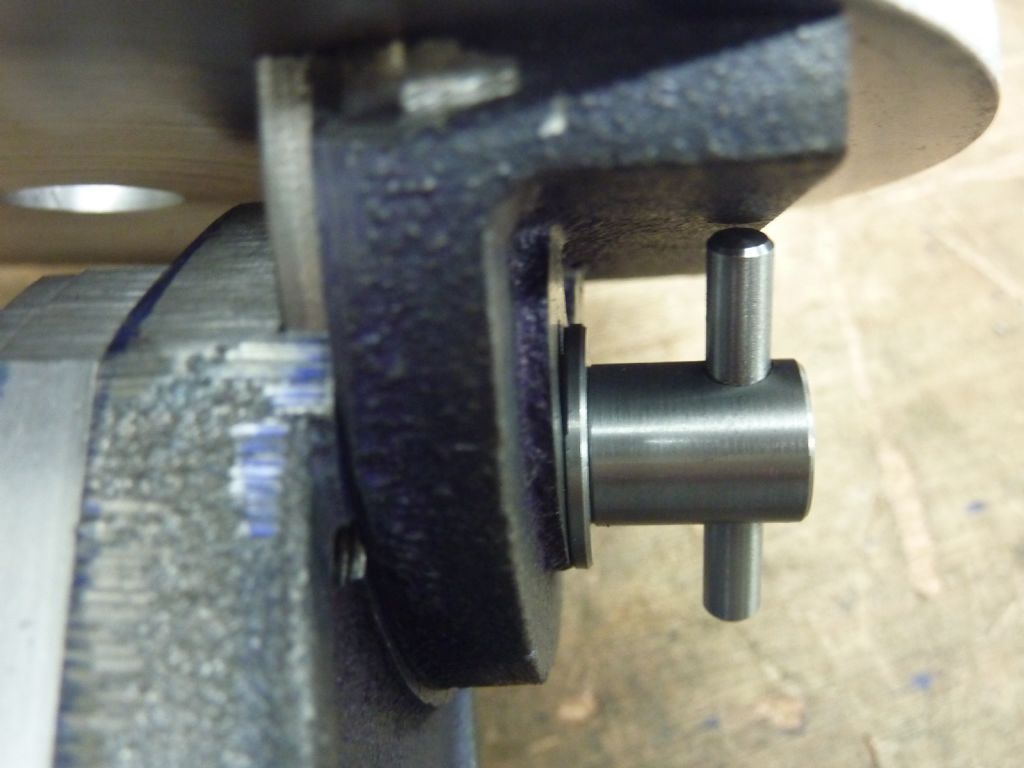

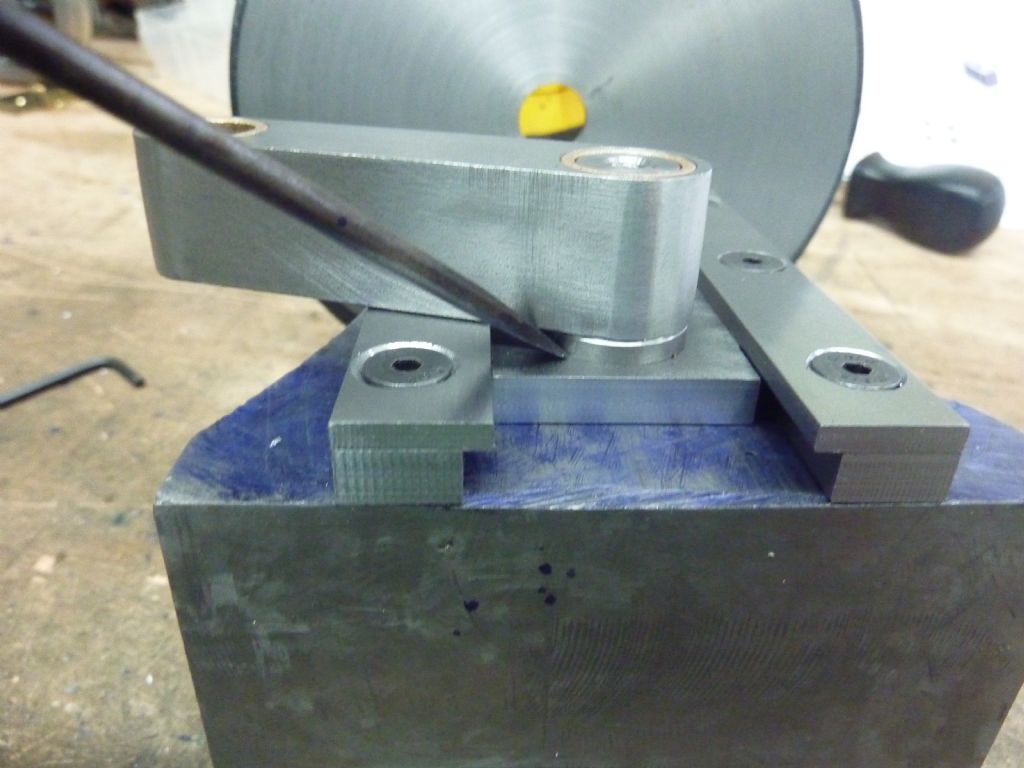

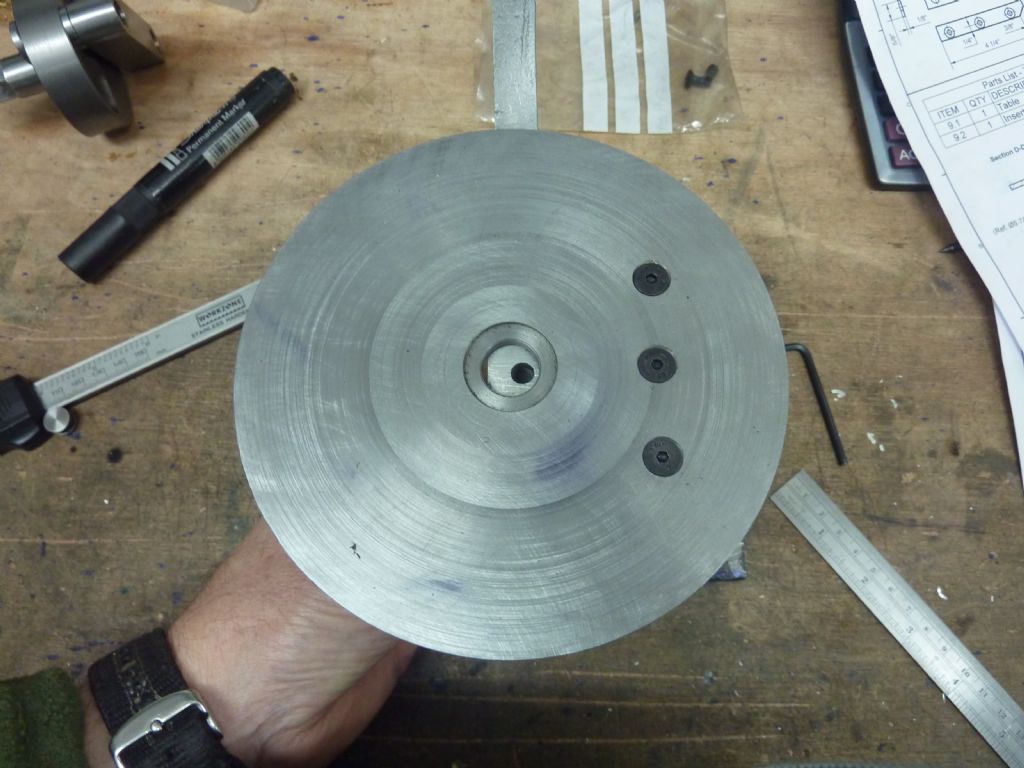

The table is tiled by three cams – sheet-steel discs screwed eccentrically to shouldered bushes that fit a cross-shaft on assembly. I turned all small parts a while ago, queuing them for cross-drilling and tapping the grub-screws holes on a shared second-operation set-up on the mill.

And so unto the cam plates, yesterday and today, and the clangers. (Without a soup dragon in sight.)

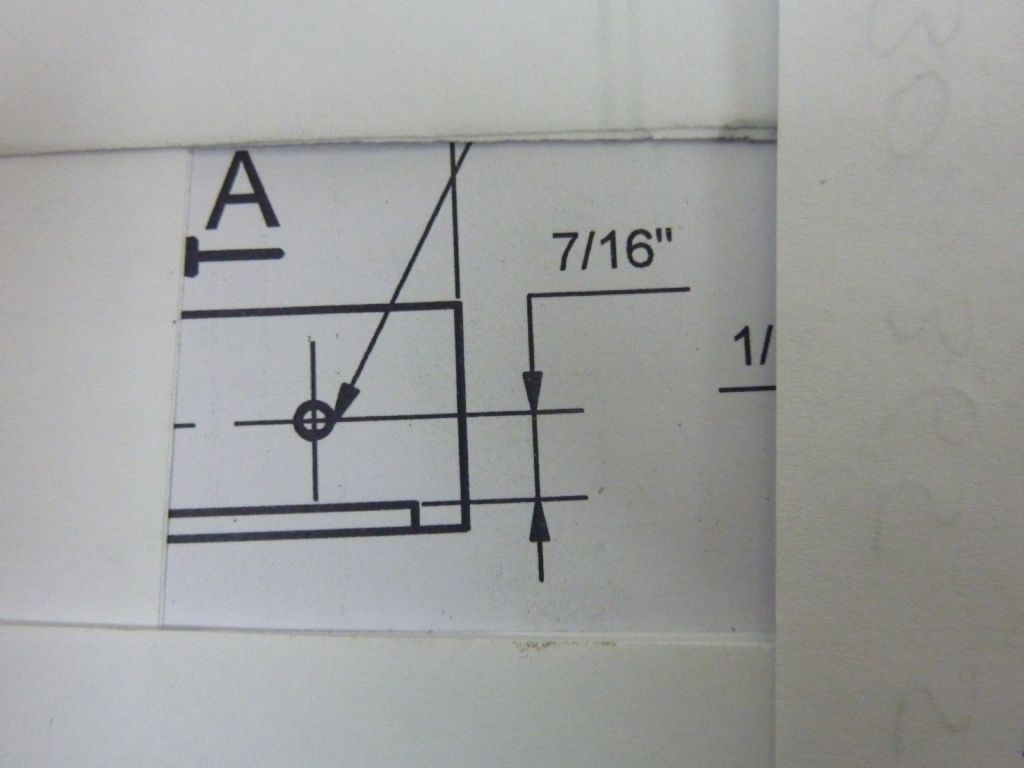

The cam plate blanks are nibbled-out with two 3mm holes that the drawing says are 2 " apart. The booklet with the drawings assumes making them entirely on the lathe, so these holes are for screwing them to a wood backing-plate for holding on a faceplate or 4-jaw chuck.

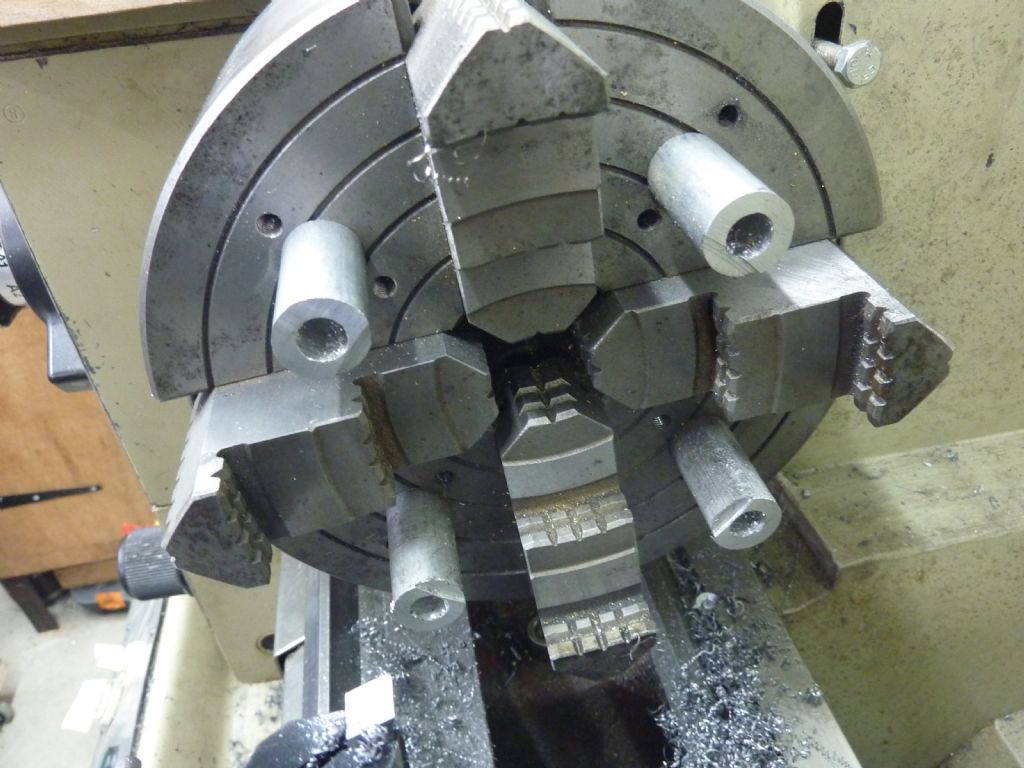

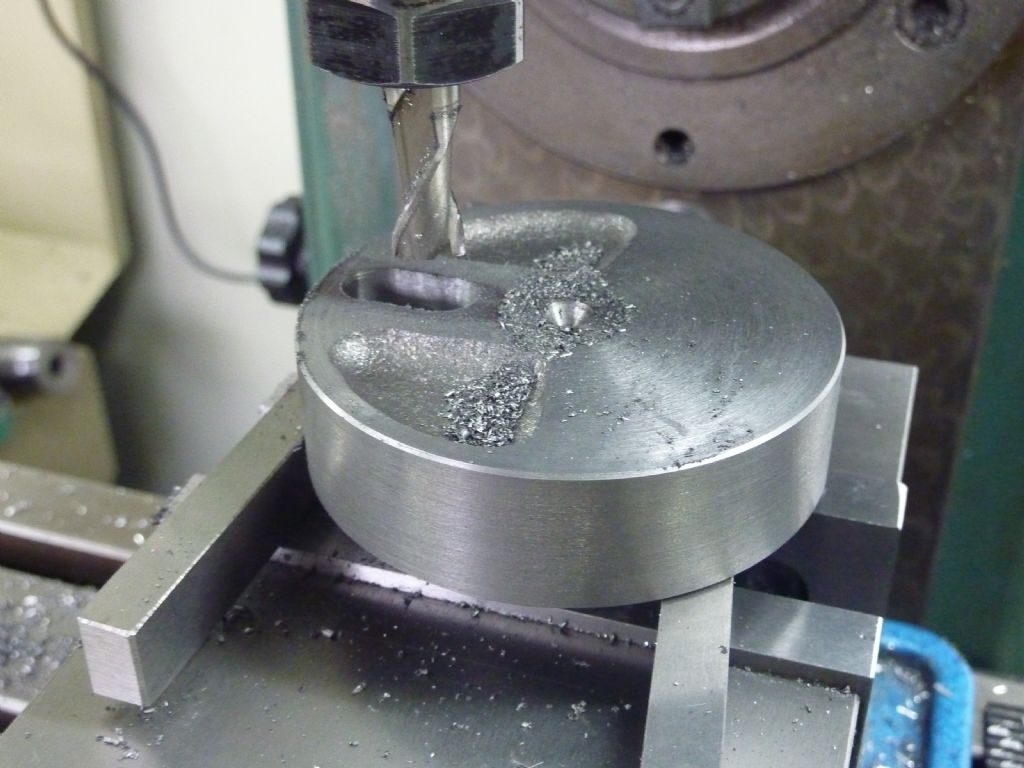

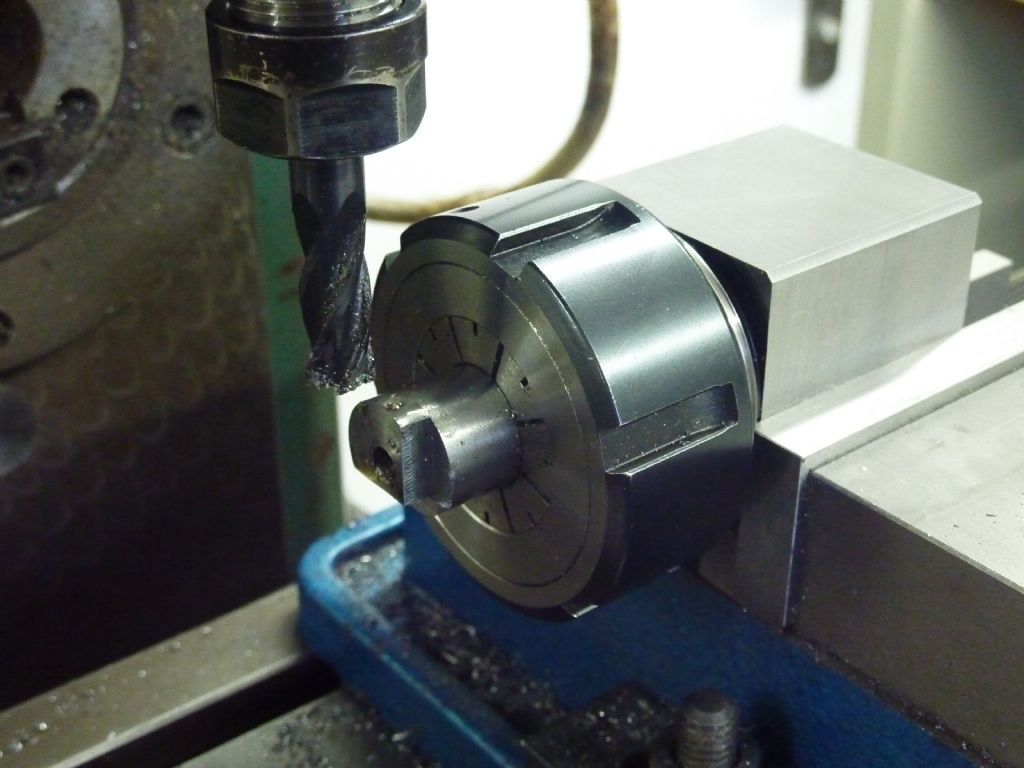

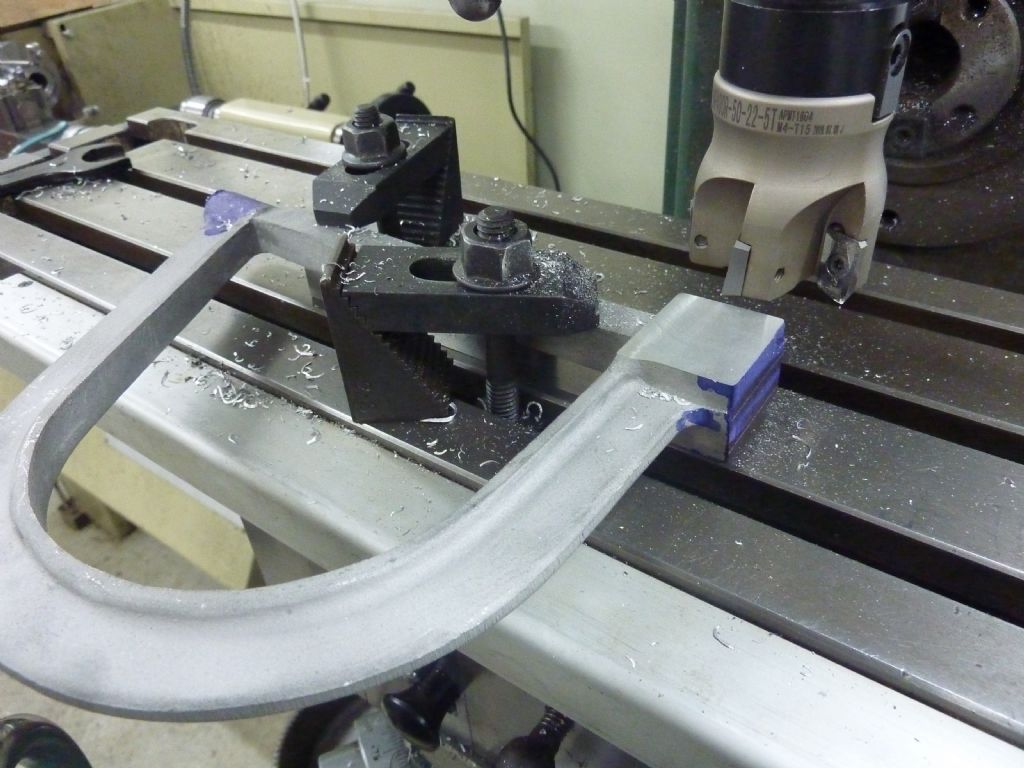

I elected to do all except trimming the nibbled edges on the mill, so faced both sides of a slice of aluminium bar in a 4-jaw SC chuck, transferred it still in the chuck to a nose-piece on the rotary table locked and set by a swinging-arm centring indicator (from Machine-DRO), and went into battle with the resulting loss of working height under the spindle.

Knowing I could rely on the accuracy of Hemingway's prepared sheet-metal parts, I took the drawing's stated 2 inches spacing for those holes at East and West as gospel, drilled and tapped the disc M3 for them, added a third at the South, another in the centre, 2 to align with the 3mm screw holes that will hold the plates to the bushes, and a pilot for the shaft hole.

All courtesy of the DRO (also Machine-DRO), and care always to wind right back then wind to position, from the same directions. My mill, a second-hand Myford VMC, has a fair amount of backlash and a strange "jumpy" bit in the middle of the long travel.

Started to screw the stack of blanks to the jig with the first 2 M3 jig-holes….

'

Clanger One.

They were slightly too far apart….. I had to enlarge the punched holes by 0.5mm. The problem? I had not verified the plates! The drawing innocently said 2 inches apart, as all dimensions except fastenings are in inches; but if working to the building notes that distance is not critical and they were actually 50mm apart!

Sorted that by careful enlarging, re-fitted the stack to the jig; drilled the other plate holes and added the extra screws.

'

Shaft hole next. Stop. Think. Examine drawing.. Opened up hole in stages; all tools directly in the R8 collets due to the lost head-room. Added further clamps as the drilling showed the tower of metal was not very rigid.

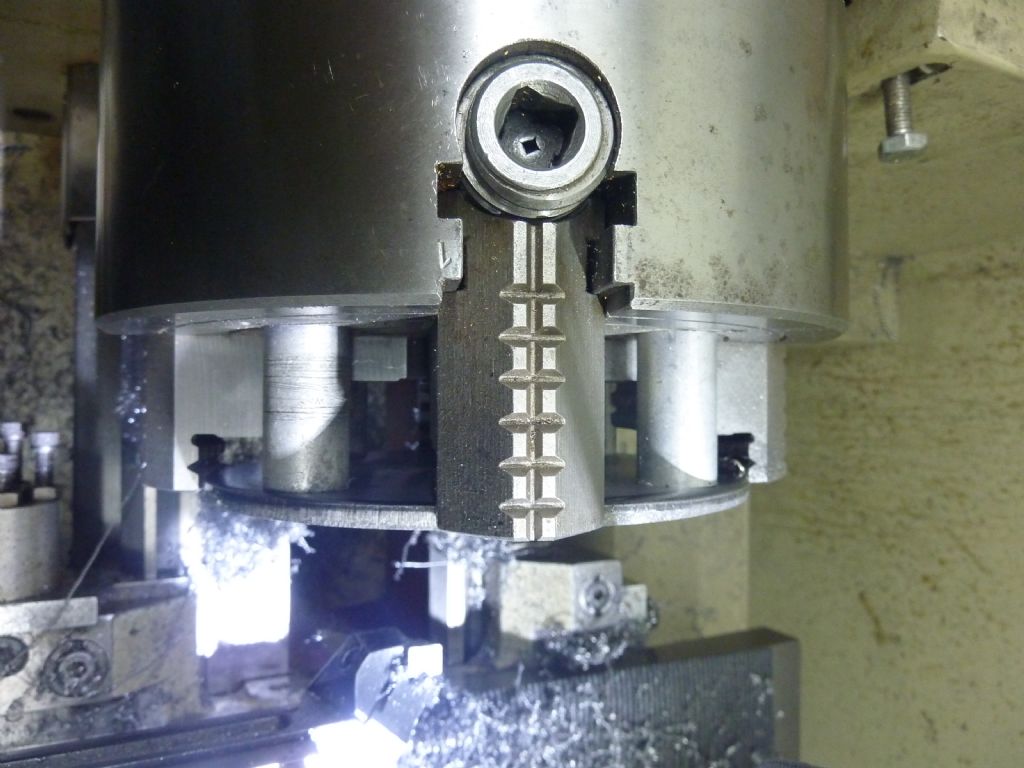

Next, the boring-head; a nice bit of kit, unknown make but labelled "Made in France for Gamet", and metric feed. I bored through all three for the bush with the smallest (by only a few thou) diameter mounting-shoulder; reducing the other two bushes later on a temporary mandrel.

Phew! Finally, I transferred the chuck / jig / plates assembly to the lathe to clean the edges.

'

Now Clanger Two appeared.

The jig was right but the cam stack was some way off-axis, shown by the central M3 screw orbiting. After all that careful planning, setting-up and machining. The nibbling and a stock edge-scar had hidden this previously.

What the…? My comments were rather less melodic than the knitted animals' conversations.

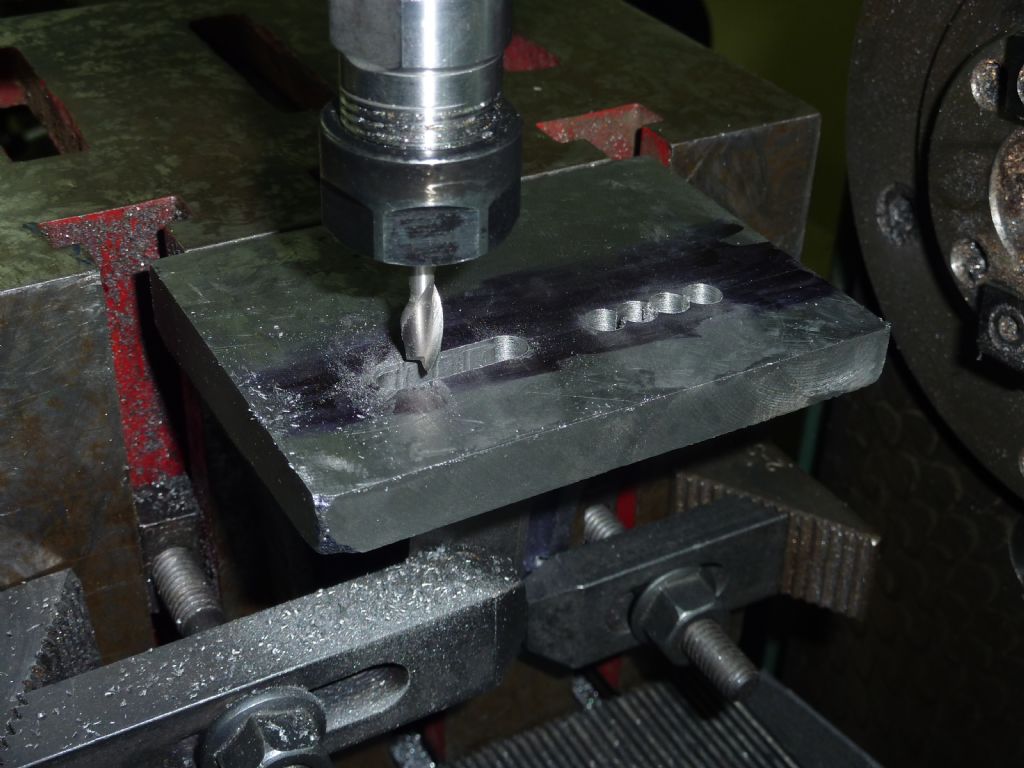

Resigned to reducing the cams' finished diameters, but I think not functionally, I moved the jig and stack to the independent 4-jaw, centred by the middle hole, trimmed the edges.

Finally, I milled off the segment specified, to clear the optional feed-screw. I have not bought that but it's sensible to allow for it at this stage. Luckily I'd marked the cutting-line by centre-drilled dimples before the disturbing, for simple re-aligning.

'

I have thought hard and honestly cannot see where It had gone wrong. Probably, I mis-read the vital X-travel on the mill so set (X = 0) in the wrong place, but won't know until I test the rotary-table again, having left the machine locked back at (0, 0) by DRO.

Possibly, the punched wood-screw holes were slightly off-centre originally, not affecting the intended method of machining nor the cams' function but doubling the " error " if I had accidentally overturned the stack in re-fitting it to the jig.

At least I hope it was just my setting error; and not some effect of that sticky bit of travel…..

Buffer.