Hi Ian

To Michaels comment Re Epoxy concrete

It would be quite easy to make a base made from epoxy concrete. 15% epoxy and 85% Sand and 5mm aggregate both by volume.

Prepare timber or MDF formwork making the inside dimensions the size of the base you require. the formwork can be clamped directly to the bed. the bearing rails on your machine bed are to be left exposed within the formwork. other bed areas can be masked off, use two or three layers of masking tape to create clearance. the edge of the base plate should be kept at least 20mm away from the v-way to avoid a fragile sharp half v being cast. it may chip.

for v-ways with a flat top as most have these days normally around 8 to 10mm wide, cover the small flat with a couple of layers of masking tape, this is to create the clearance that is standard best practise on machine slides. the bas should bear on the sides of the v-way and the bearing flat only.

When I did this on my lathe (Epoxy bedding the cast steel saddle after a bed regrind, it worked perfectly. The saddle is ) it is very heavy I had to crane it into position it has been in constant use for several years now. In this case I used pre set jack screws set in blocks of steel attached to the saddle using the way wiper mounting holes to mount them, to pre position the lathe saddle then applied the epoxy to the saddle and carefully placed it on the lathe bed sitting it back on the jack screws to set. Positioning the saddle in three planes took hours! The "Pour" only a few minutes

Once the formwork is in position all small cracks and holes should be filled with plasticine and masked off with tape, otherwise the epoxy will weep out.

Before the epoxy is placed (15% epoxy aggregate has the consistency of peanut butter) the entire inside of the mould and the exposed ways need to be coated with mould release available from fibreglass suppliers who also supply Epoxy. Use plenty I used a couple of coats ….. Epoxy sticks very well. Be careful not to scratch the mould release. I used a small stick to gently tamp the epoxy the top will self level within a couple of mm if you give it a hand.

Once the epoxy has set the formwork can be stripped and the base lifted off the bed, it may need a tap around the edges. to finish the casting sharp edges can be rounded with a small angle grinder. Any small holes and blemishes can be filled with body filler and sanded. The same way you would prepare a cast iron casting ready for painting.

The height of the base mould should be the height you want less the thickness of a mounting plate made from steel or aluminium less about 5mm for epoxy sand grouting I will explain grouting later. the base mould should also have several cast in position threaded steel inserts. These will be used to attach the steel top plate onto which you will attach whatever device you are building.

If you plan to machine the top plate after it is grouted in position you may wish to drill and tap any holes before to avoid drilling into the epoxy concrete later (Epoxy concrete is easy to drill with a masonry bit but it is not very kind to taps, or use a tap nearing its use by date)

After the base is cast and the top smoothed when wet it will not be dead level and planar to the base probably within a couple of mm, clearly not what we want.

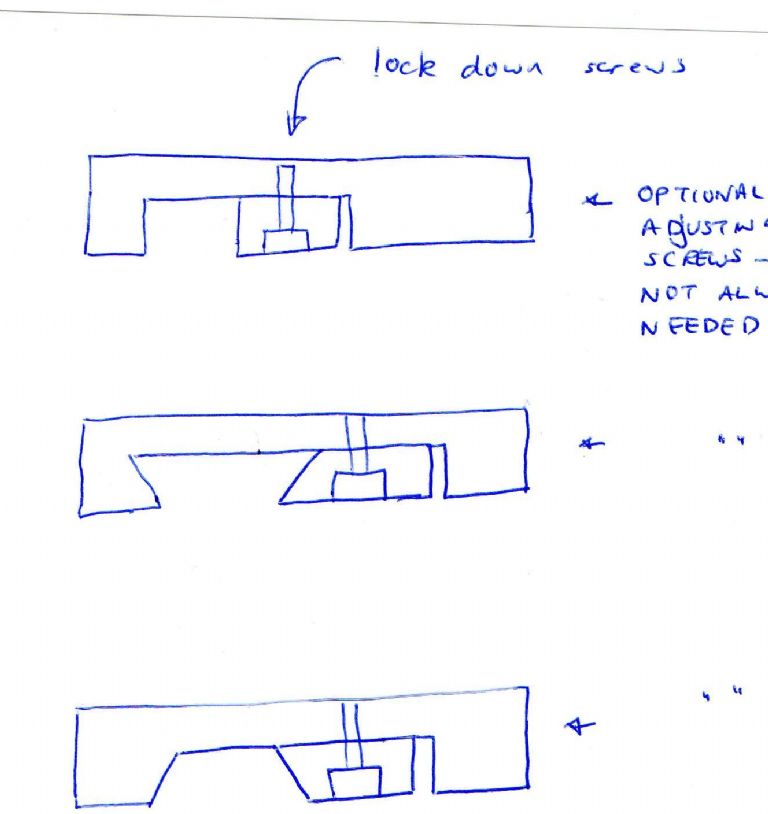

Aligning the top plate? I deliberately made this a second operation. It would be possible to pour the whole base in one hit with a precision made mould, however you would spend a great deal of time preparing it. Instead I propose using the steel threaded inserts that will ultimately hold the top plate in position to level the top which can be precision set up in position on your machine using 3 or four small jack screws inserted in tapped holes in the base plate

The jack screws bearing against the epoxy base can be set, opposing and together with the mounting screws, to position the plate in line with the your machine bed, you should be able to align it very accurately indeed. A dial indicator on a sliding block running on the machine bed could be used. maybe a precision level would help if your machine is truly level. The reason for the 5mm gap is to allow the accurately positioned top plate to be epoxy grouted to align with the base plate.

Once the base plate with aligned top is set up the assembly could be turned on its side and the gap filled with an epoxy grout maybe 20% epoxy with sand only on aggregate (it has to be runny in order for it to run within the 5mm gap) If the gap is too small the epoxy may refuse to fill the slot.

The bottom and two sides having been masked off. The jack screws can be cut of flush if they refuse to come out. Grouting machine bases to the floor and assembling components aligned on jack screws is often done today.

Unlike Water based concretes epoxy has minimal shrinkage most papers state it to be "negligible". This does not apply to solvent based polyester resins as used with fibreglass boats, they have significant shrinkage.

Interestingly there is almost no machining apart from the threaded inserts and drilling a few tapped holes with this method. Oh and a bit of woodwork. Allow a little more epoxy for testing your mix before doing the real pour. You will find it an easy process once you have done a couple of small test runs.

Regards

John

Edited By John McNamara on 05/08/2013 15:55:42

Edited By John McNamara on 05/08/2013 16:02:02

MICHAEL WILLIAMS.

.

.