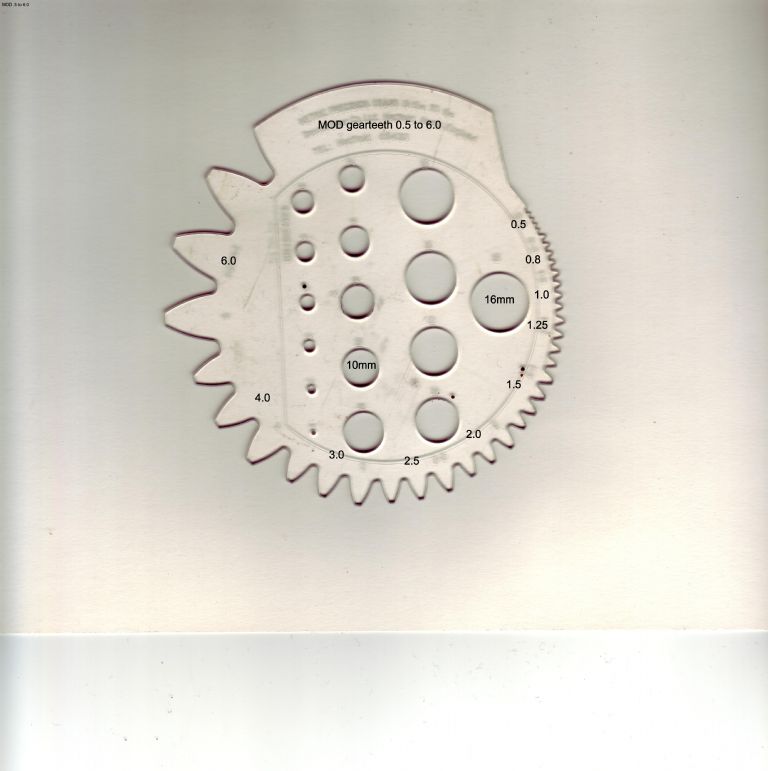

You should be able to determine roughly what size of tooth you're dealing with by measuring the tooth depth. If it's a metric gear (Module), then the tooth depth is a little over twice the Module – e.g. if the tooth depth is 2,25mm or so, it's possibly a 1 Module gear.

If you're dealing with a DP gear (perhaps more likely in Model Engineering) then the method is similar. Full depth of tooth on a DP gear is 2.157/DP. So if your tooth depth is a little over 1/8", then it's probably 16DP.

Once you've determined the approximate pitch size, then you can use the David Brown Base Tangent method, whereby you use a vernier caliper to measure over 2 or 3 teeth (it depends on the number of teeth in the gear) and you can then decide whether it's (say) 8DP or 3 Module.

Be aware that there are two standard "pressure angles" for gears – 14.5 degrees and 20 degrees. This affects the shape of the teeth and hence the Base Tangent measurement. Older DP gears may well be 14,5 deg, most module gears are 20 deg.

Machinery's Handbook gives dimensions for BTM, but in my 1957 edition they hadn't invented millimetres.

Peter Krogh.