Posted by JasonB on 25/07/2019 13:05:40:

Posted by jacques maurel on 25/07/2019 11:04:27:

Be careful as the number of divisions must be a submultiple of the number of teeth!

JM

Why would that be? The factory gear is 20/21T and the dial divided into six yet from the chart I posted above it will work with a large range of pitches, infact all that the gearbox can produce.

The dial is divided into six but the usable divisions of the dial with any particular gear have to be a submultiple of the gear's teeth. For the 21t gear, you can only use 1, 3 & 5, which would be 7 teeth apart. For the 20t gear, you can only use 1 & 4, which are ten teeth apart. Poor 2 and 6 never get a look in with these gears.

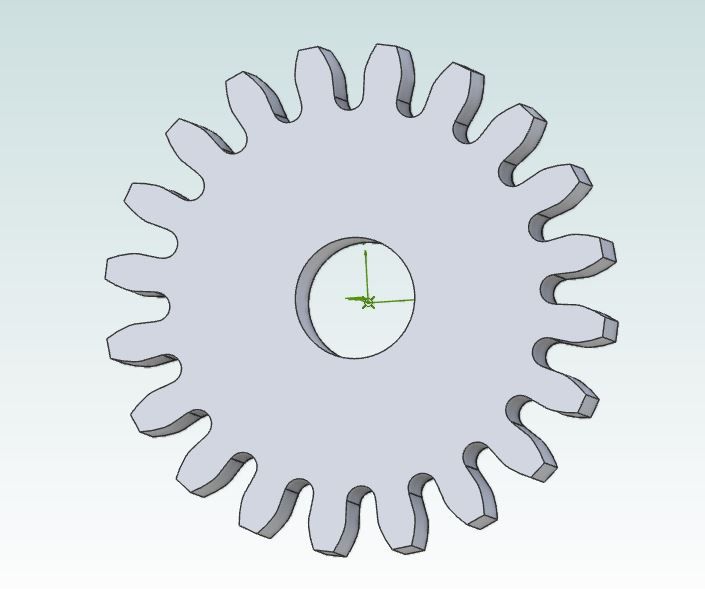

Could you amend your 3D model to the correct pressure angle? Think about it: is any module gear in the world likely to have a 14.5 degree PA?

The 14.5 degree PA corresponds with the 29 degree thread angle of imperial ACME. Metric trapezoidal has 30 degree thread angle, which would be 15 degree PA (I wrongly stated that it would be 30 degrees in a post above but cannot find any way to correct my error).

Michael Cross 4.