Ignore this if you are already up to speed on the Ford drawing:

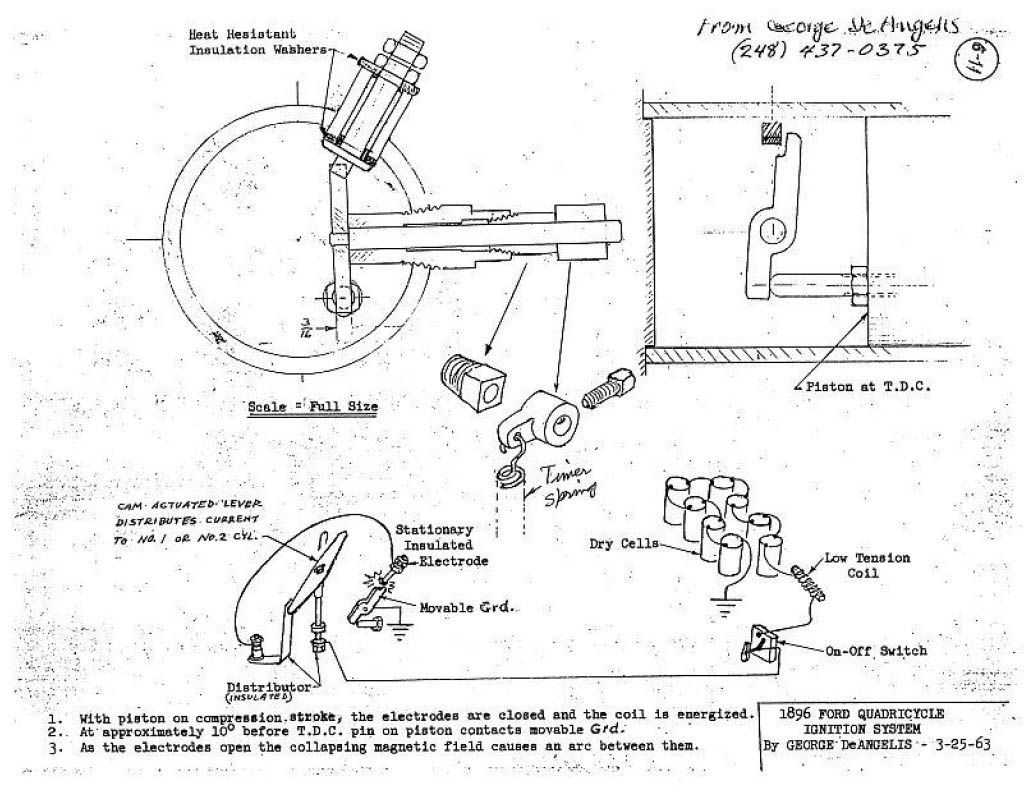

This shows a very primitive (early) version of the final option I suggested it might be. The circle top left is the view down the bore if you take the head off. Top right of this is the insulated 'plug' which produces the spark. It is not clear how this is fixed in the bore, but it needs to be insulated against lots of volts, heatproof against petrol flames, and not able to be blown out by the repeated explosions.

The screwed fitting at the right – fitted through the bore with a tapered thread (a tradition which was later used for sparking plugs and lasted to the end of the model T in about 1928) – carries a central spindle, on the inside end of which is a lever as shown to the right of the page – and the bar carried by the spindle rests against the projecting electrode of the plug. This connects the plug to earth (chassis) and completes the circuit (we'll come to that). When the piston approaches the head on the compression stroke, a peg on the piston thumps the other end of the bar, and disconnects this earthing connection, causing a spark. The lever is sprung loaded to hold it against the plug (square-head fitting, and timer spring details are shown), so as soon as the piston descends, the connection is once more connected to earth.

At the bottom of the page a sketch shows a 'distributor' but actually only some bits of it. Somewhere on the engine there is an insulated distributor post carrying a pivoted blade, which is moved to and from by a cam (eg). the end of the blade makes contact alternately with a blade on the sparking plug of each cylinder, switching on the current to that cylinder so that there is current flowing as the piston starts to rise on the compression stroke for that cylinder. When the current has stopped and the spark has jumped, the pivoted blade is flicked across to the other cylinder ready for its piston to start up the bore.

The timing of the piston opening the circuit is fixed by the geometry of the piston peg and the timer blade inside the cylinder. This is not clever, as it cannot easily be be adjusted from outside, and to start with you won't know what timing to use. Too late and you will make lots of heat but not much power; too early and you risk breaking your arm of bending engine parts if the explosion pushes the piston back down before tdc. I suggest that you think hard about some sort of adjustable plug so you can try different settings – perhaps by using an L shaped rod end and rotating it (once the engine has cooled off a bit) to meet the piston rod higher or lower as you find best. It would be better to have adjustment 'on the move' but Henry Ford was very early with this design, so this would surely have been tried on his next version.

On the other hand, timing of the switching on of the current requires easy adjustment of the 'cam actuated lever' and its related parts. Switch it on too early and you waste battery power and heat the coil too much, too late and the coil does not have time to build up a decent wallop of spark.

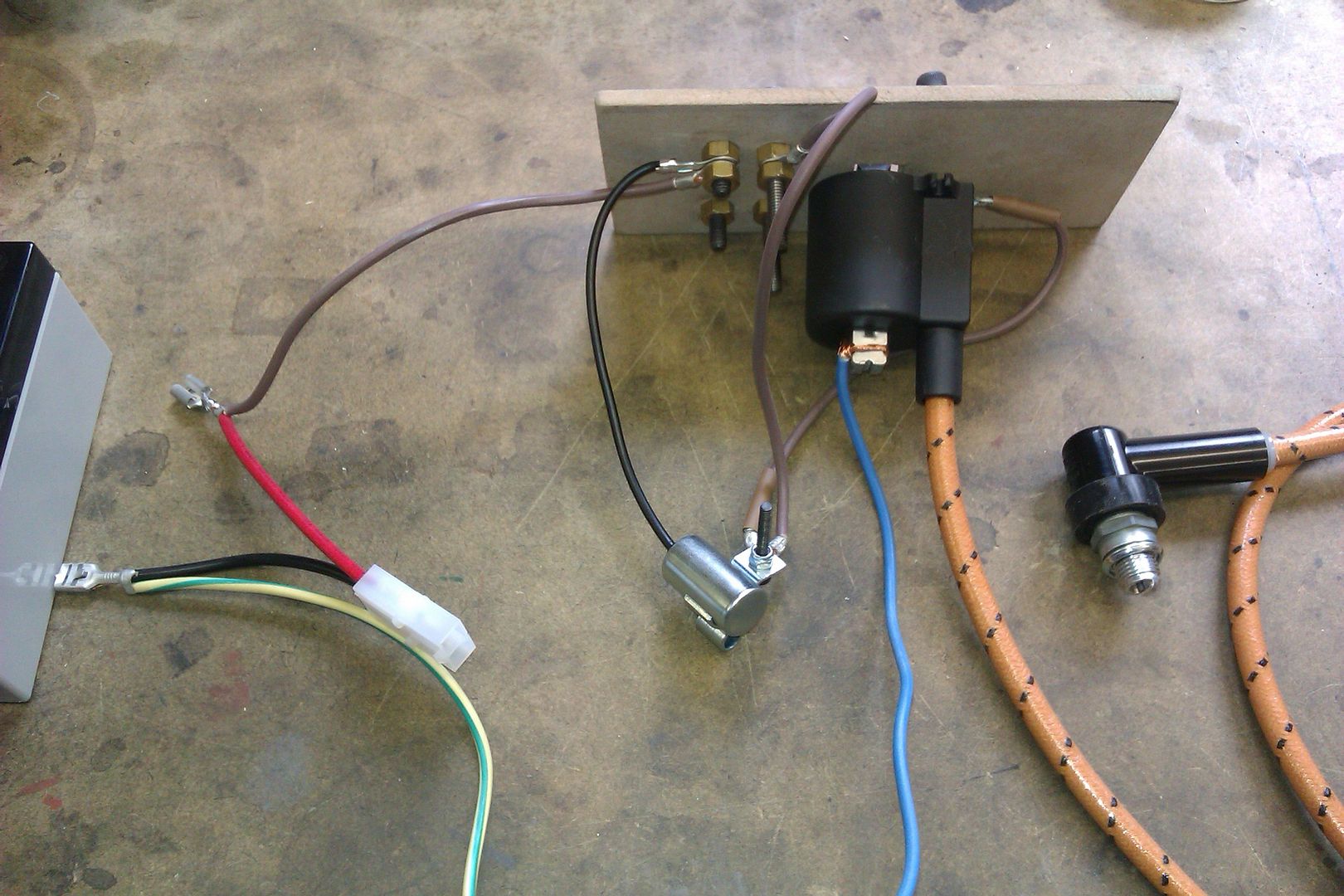

Along the bottom of the page is the circuit. The dry cells would have been 1.5 volt torch battery type cells, all connected in series to give 8 x 1.5 volts = 12V. The low tension coil (there is only this coil, no high tension coil at all) is a simple winding of 200 turns or so of insulated wire round a laminated steel core. As is suggested above, a suitable coil may be found inside an old fluorescent lamp fitting. As this coil is a magnet switched on and off as the engine runs, it will attract any iron or steel bits around – not a good idea. Make a special box for it so this cannot happen – but leave space around it for ventilation as it will get hot in use. For modern purposes, a small car or motorcycle 12v battery would suit well instead of man-sized torch batteries. You will need to restrict the flow of current to about 2 amps, by adding a resistance in the circuit, if the resistance of your chosen coil is rather low.

A period detail in relation to any visible wiring: In 1896, there was no stranded (flexible) wiring with insulated covering. What would have been used is likely to have been DCC – Double Cotton Covered – plain stiff copper wire, given some flexibility by winding it around a rod of say 8 or 10mm, so it would dangle and bounce around rather than breaking off straight away over the first pot-hole. A reasonable modern version would be to use a small size of pvc covered braided wire, and where it shows, use an extra amount and wind it on a bit of bar before fitting to look (vaguely) like the original. This will last much longer and short out much less than the original. The wire will only be carrying about 2 amps so the smallest vehicle-type wire will do nicely.

I hope these details will help as you get towards the magic day when your mates stand idly by and say 'Go on then, start it up … '

Cheers, Tim

Brian H.