Jack Radford's modifications to the machine itself appear from the above, simply some drilled and tapped holes, and possibly a spot-faced area, in the apron and lever boss. So if it proved disappointing you won't have spoilt the lathe too much.

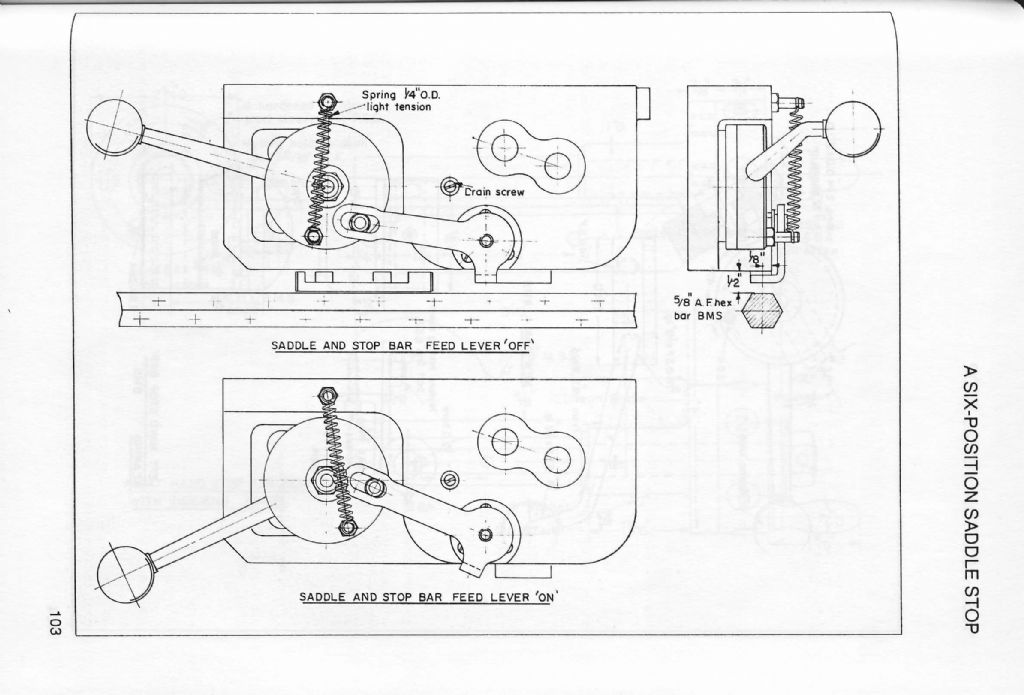

It uses a simple lever and over-centre spring, operated by a tappet locked into place on a bar mounted below the saddle in some way (brackets on the lathe's holding-down studs?); but the radius ratio that presumably gives fairly rapid action also produces a large mechanical disadvantage working for half its stroke against the spring.

That 1/8" delay is quite a lot, but accounted for by placing the tappet appropriately early.

'

A possibly better though more complicated arrangement (and which may be the Ainjest principle) would use a sprung lever or plunger to open the half-nuts, with the spring triggered by the lever.

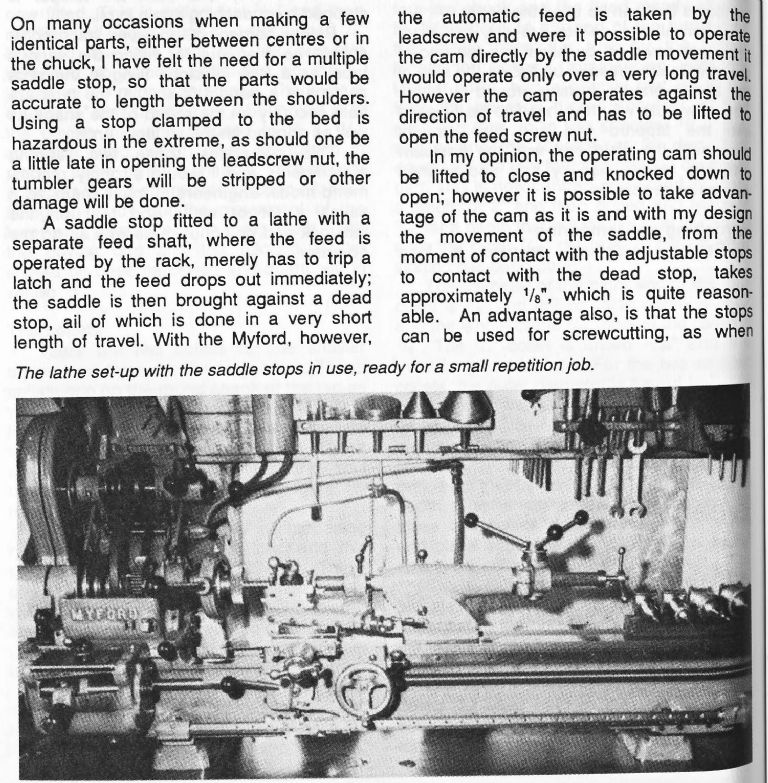

This attachment on the Myford would allow repetition plain-turning passes to a shoulder, though I think you'd need use the thread-indicator for that as well as screw-cutting, and probably to the same number on each pass. All extra wear on the indicator that is not built for heavy repeated use.

(The Ainjest has this repeatability built-in, but is for threading only, on lathes with separate feed-shafts.)

'

Drive dog-clutches should give repeatable stop-points useful for plain-turning, but also having to wind the lathe back by the lead-screw for each pass, manually or by revering the motor, rather diminishes that advantage for screw-cutting. In such cases it may be easier to disengage the drive-belts and use a mandrel handle, with a simple solid stop-block on the bed.

'

There is an alternative – George Thomas designed a Retracting Top-slide for the Myford Super 7, also for rapid screw-cutting, but is a far more complicated item, and you still need disengage the half-nuts in the usual way.

'

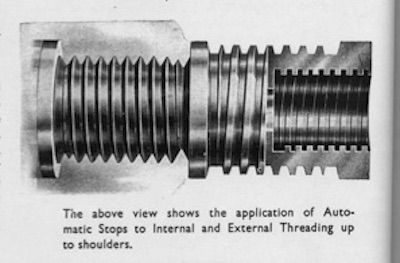

Incidentally, Millhill Supplies stock Ainjest units for Colchester and Harrison (only) lathes, but judging by MS' web-site photos, whether suitable for early L5s like mine is another matter. Probably at prices that make the virtues of patience and care in manual operation rather more valuable – and virtues are free! The publicity gives as example, large BSP internal and external threads on an aluminium-alloy fitting; 5 passes each, >1000rpm.

However, their illustrations usefully show that the Ainjest uses only the lower half-nut, of bronze, apparently controlled by vertical guides and snapped clear of the lead-screw by a pair of springs. So making an attachment on those lines, but simpler and designed to fit a Myford, may be feasible. Though I'd make the half-nut move upwards, to help avoid it clogging with swarf.

Edited By Nigel Graham 2 on 24/04/2021 11:16:12

Anonymous.