Somewhere lost in in my library is a book containing advice on relay contacts. From memory it’s similar to Bill’s (peak4) information above, except it goes more into the whys and wherefores.

Briefly, the ideal contact material is decided by how much current flows and for how long. As an electric arc is much hotter than oxy-acetylene, up to 20,000°C, switching a heavy current requires fast acting mechanics and a contact material that can take a physical and electrical beating. Broadly, tungsten or mercury wiped contacts for tens of amps and a noble metal like Rhodium, Palladium, or Platinum for anything smaller. Melting points:

- Silver = 961°C

- Palladium = 1555

- Platinum = 1770

- Rhodium = 1965

- Tungsten = 3400

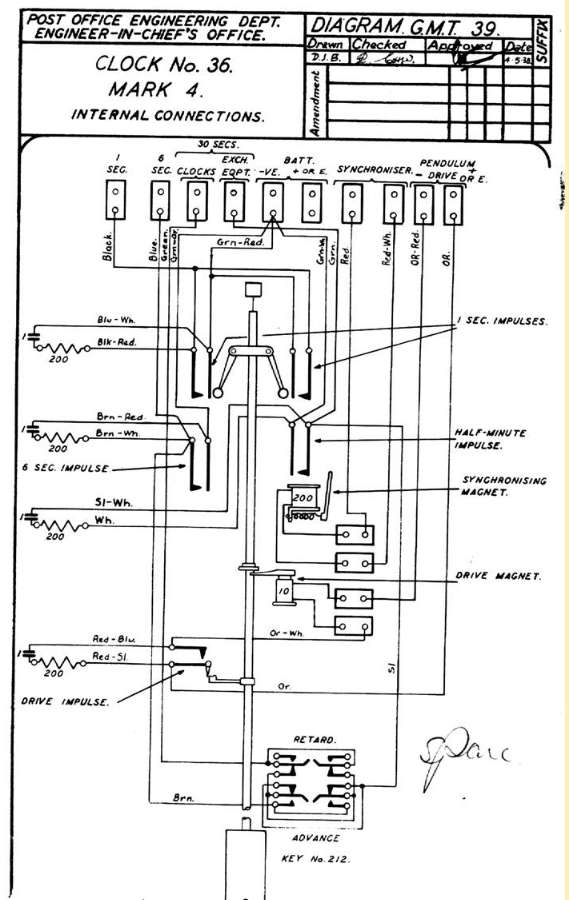

To keep the contacts clean, relays are designed with a wiping action that matches the contact material to the current it passes. Although relays look simple, they’re high-tech. When reliability matters, it’s important to choose the right type. PO relays are optimised for 80V telephony, and the contacts burn out if overloaded, and tend to clag up so small voltages won’t switch reliably.

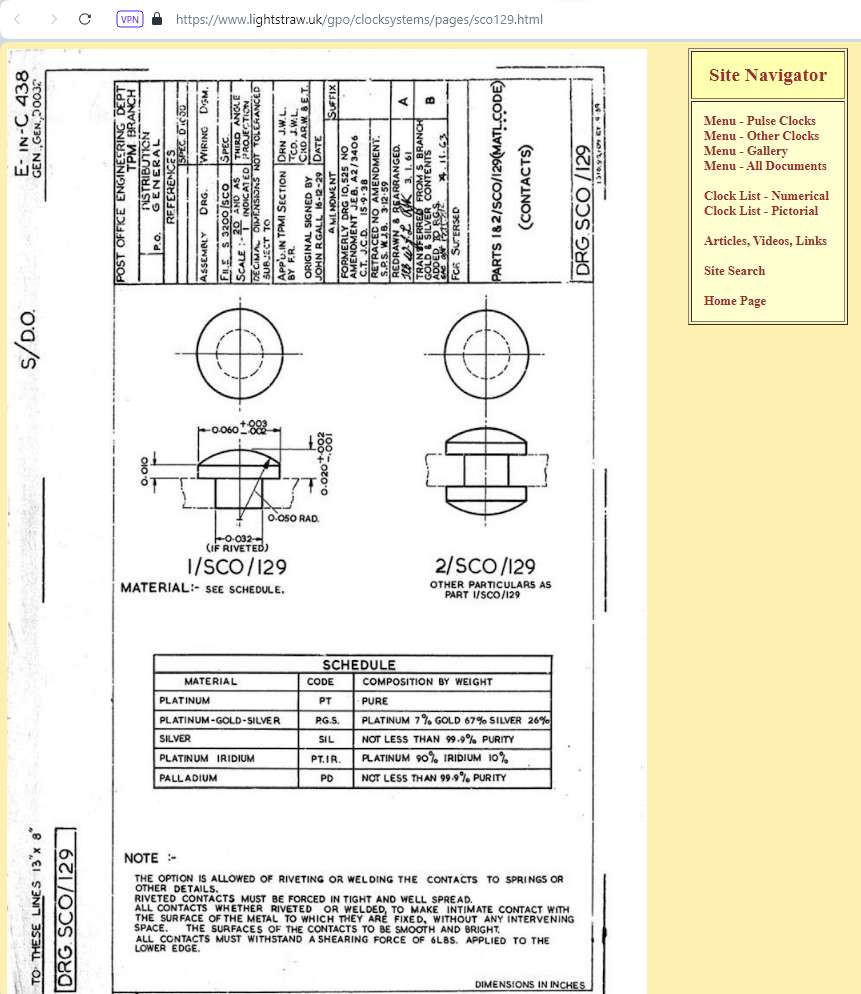

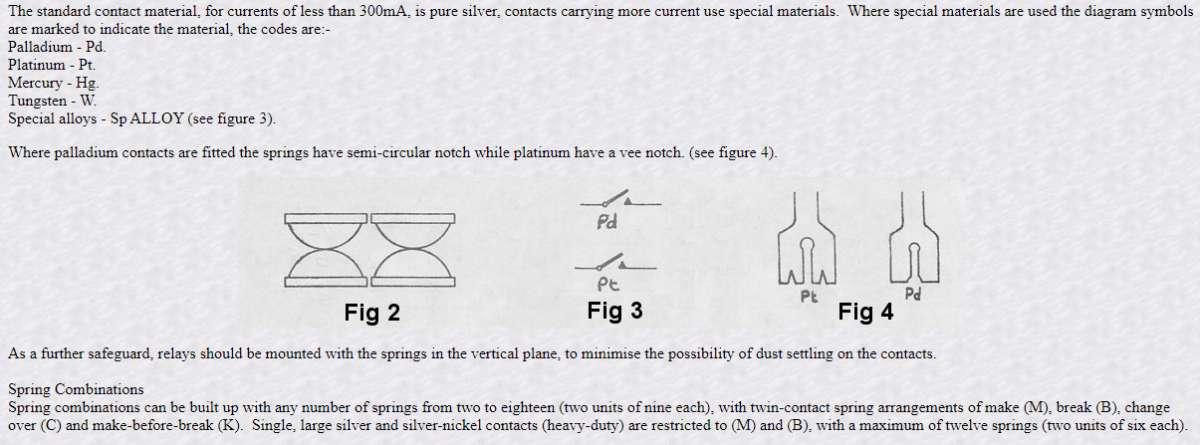

One of Bill’s documents says “The standard contact material, for currents less than 300mA, is pure silver…” That’s almost certainly what Derek’s clock needs. Silver is high-conductivity, and – most important – Silver Oxide is conductive, so tarnished contacts will still work. Only suitable for light duty though, because of the low melting point. Sterling Silver is easy enough to obtain, pure if you can find it.

Switching an inductive load like a motor or electromagnet is likely to cause voltage spikes that maintain arcs. Arcing causes current to flow for some time after the contacts open, which might upset set the mechanism, whilst the high temperature erodes the contact material. The amount of metal removed by a small spark may be tiny, but it’s hot enough to evaporate Tungsten, eventually destroying the contacts. For DC the cure is either a capacitor (about 0.1uF) across the contacts, or a diode across the coil; AC tends to self-extinguish.

Rather than fix the contacts, how about cheating? Before semi-conductors ousted them completely, PO-type relays were widely replaced by Reed Relay telephone exchanges. Designed for small signal work, reed relays consist of a sprung contact inside a sealed tube; they’re miniature and much more reliable. Disconnect or insulate the existing contacts, and substitute a reed-relay actuated with the existing magnet coil.

I’d go a step further and use a transistor! Otherwise, as Bill & Duncan suggest, the easiest way to get good relay contacts is to scavenge them from a commercial item.

Most metals will work as contacts for a while, but they melt, corrode in air, and mostly have high resistivity. For that reason TIG wire is unsuitable, as are most ordinary workshop metals. Carbon might seem suitable because it’s used in motor brushes, but it’s too soft for relay contacts. Copper, Brass and phosphor-bronze are OK for wiped and knife switches where positive sliding contact is guaranteed, but not for relays.What’s the difference between a Relay and a Contactor? Not much. Contactor is preferred by the power switching community, whilst electronics and tele-communications folk tend to talk about relays, even when their relay is switching megawatts.Dave

derek hall 1.