I have actually bought Oilite sintered bearings from Simply Bearings in the UK. It was less than a tenner for both

I'm still not sure if they are suitable.

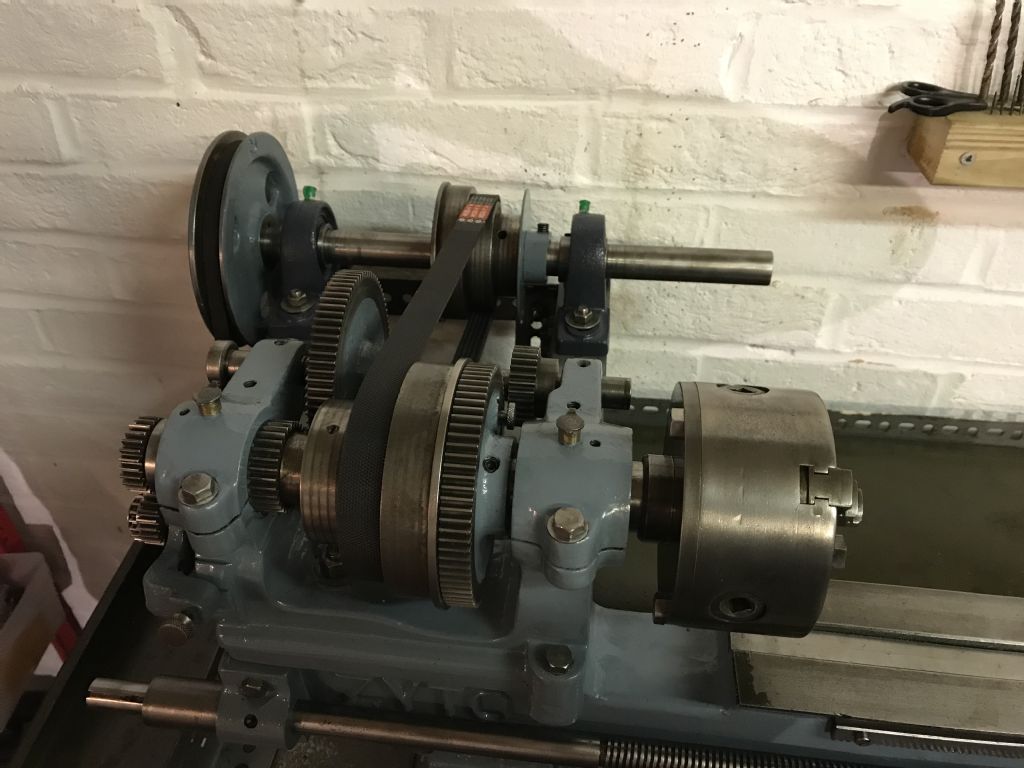

As you pointed out Duncan the lathe body does have pinch bolts on one side.

The bearings I removed are split bearings but I am sure they are not original. I remember seeing pictures in another post where someone removed non-split bearings.

Do you have to use split bearings in a pinch bolt arrangement or could I use the Oilite ones and very gently tighten the pinch bolt so the bearings are held firmly but not squashed ?

My options are:

1. Use the Oilite bearings I have bought and never oil them

2. Use the Oilite bearings, don't drill a hole in them but feed oil through the drip oil hole hoping it will soak through the pores.

3. Use the Oilite bearings and drill a hole in them then feed oil through drip holes

4. Source non-sintered split bearings that are too long, cut them to length and drill a hole in them.

Unfortunately it is catch 22 and I do not have a lathe to cut bearings to length until this project is complete so unless I found someone else to do it I would have to use a hacksaw and file.

Please continue to give the very useful feedback

Chris Evans 6.