Posted by Georgineer on 18/07/2020 10:36:20:

Just a thought: I know the power supply says "Regulated" but a lot of school DC power supplies are quite primitive, basically just rectified AC with little or no smoothing (ex-teacher speaking). The resulting ripple would easily give a buzz or hum to a circuit which wasn't quite managing on 12 volts.

George B.

Good point, or even the other way round! Bill's PSU looks modern, in which case it may automatically current limit to stop youths blowing it up by shorting the terminals. Very simple PSUs rely on a fuse, more modern (like my 1950's Triang Train Controller), have resettable thermal cut-outs, later came electronics, which play all sorts of games to protect the PSU. One tactic is chopping the voltage so the current never exceeds 3.5A: rather than clean DC the overloaded PSU outputs pulses, causing buzzing.

With luck it's simply lack of power from an unsuitable PSU. The motor is buzzing because there aren't enough amps to run it in reverse# and it's stalled. If the motor is stalled, possible to detect it by manually turning the shaft. Strong resistance in one direction, turning easily in the other means the motor is trying.

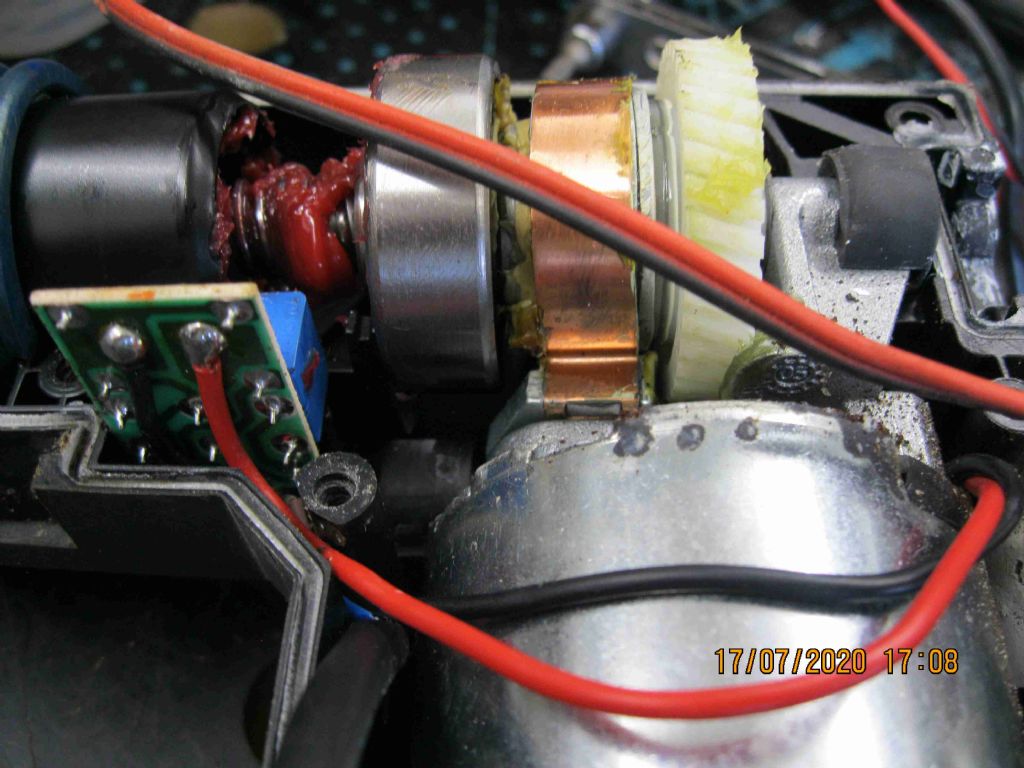

Is the motor worn, or possibly not meant to reverse? Although DC motors are reversible in theory, in practice bearings, brushes and gears can be arranged to strongly favour turning in one direction only.

Dave

# Or maybe it needs more power to run forward because years of lifting people upstairs have worn the gearbox and brushes? Reversing downstairs is light work, and the motor/gearbox might turn easier in that direction because it's less thrashed.

Edited By SillyOldDuffer on 18/07/2020 11:19:13

Cornish Jack.