Posted by Ian Skeldon 2 on 25/06/2017 20:23:28:

Trying the hacksaw blades has made me realise how poor our general quality of simple tools and engineering supplies have become. As an apprentice (many, many years ago) hacksaw blades were very hard and of course that made them brittle, but they never bent, twisted or deformed like the stuff you get now, and they lasted well, ah well reminiscing over.

Thanks Russell, I'll try to source some dearer, better quality ones and have a go with one.

Ian

It would be really interesting to test a New Old Stock 1960 hacksaw blade against a modern one to see if they really were better. Personally I doubt it: if old tools were so good, why the cars so bad?

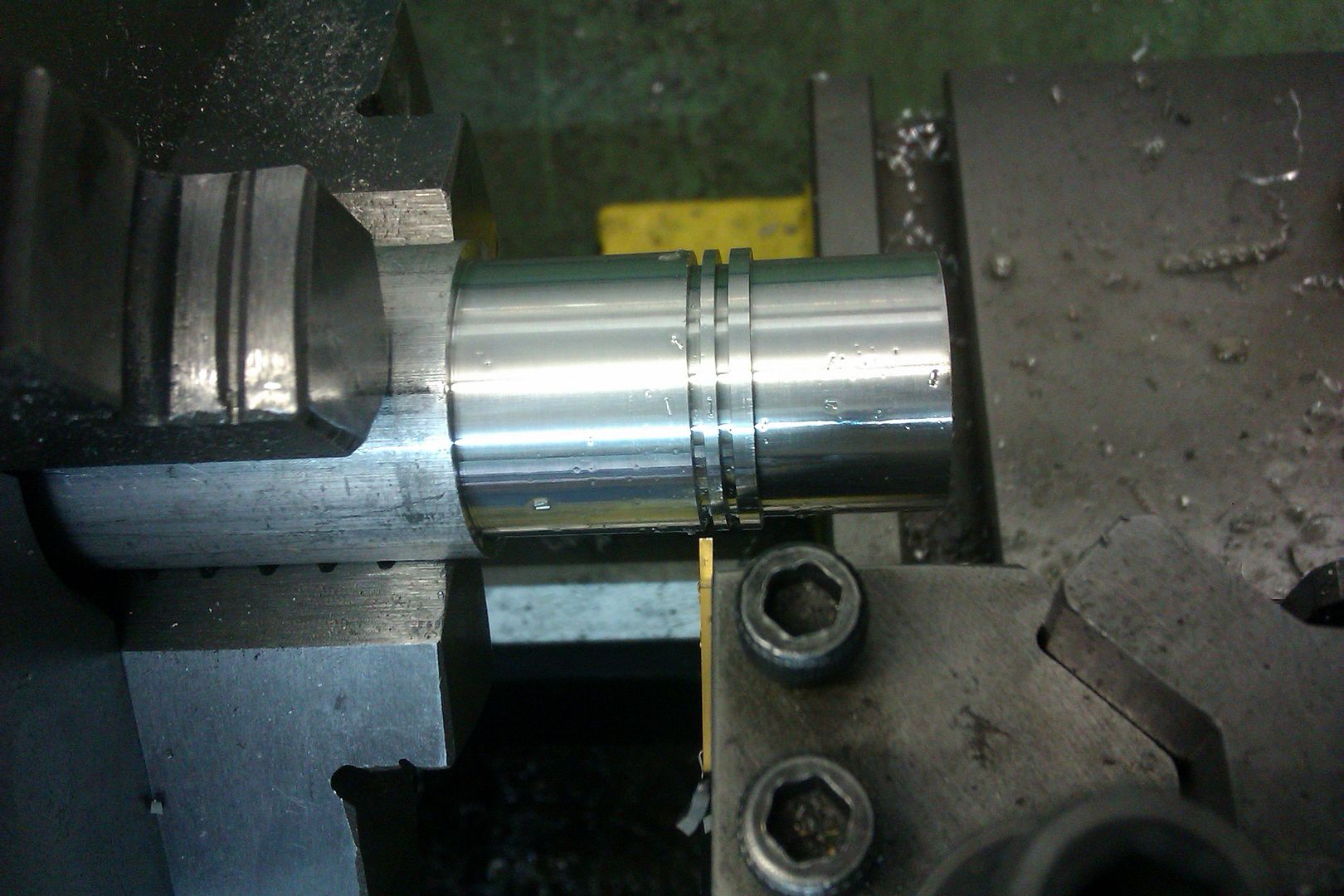

Anyway, better or not, modern hacksaw blades are rather likely to have been made differently to an older one. Only the teeth are HSS and the rest of the blade is flexible rather than hard. This means they're less suitable for conversion into a grooving tool.

Dave

Ian Skeldon 2.