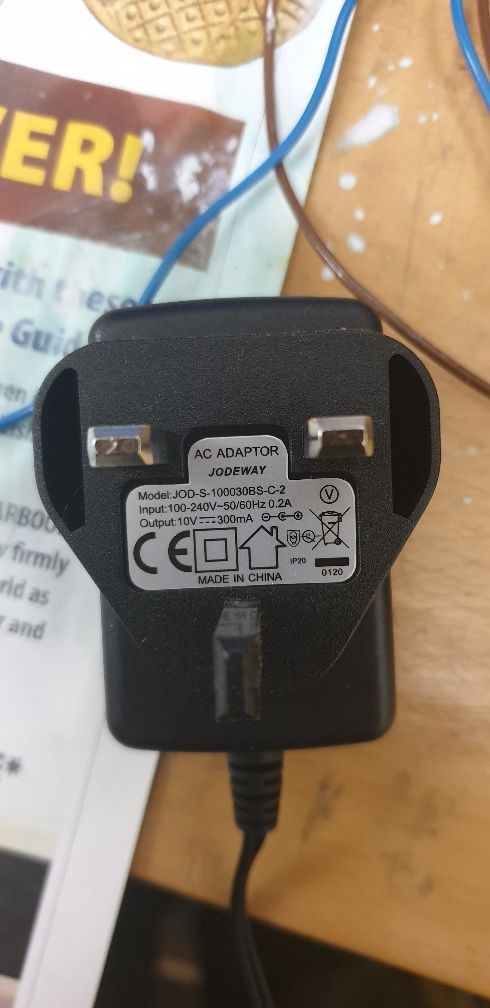

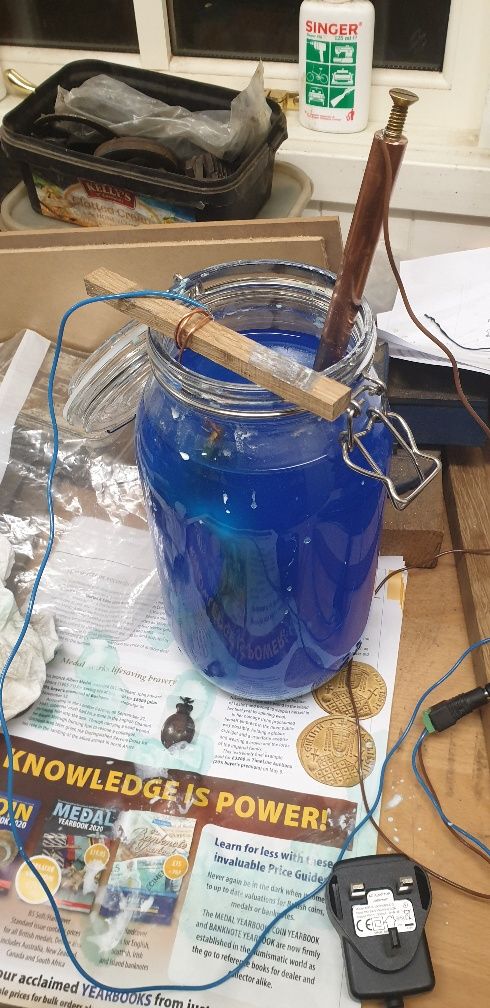

DAFT question You are using a DC supply for plating?

AC will put the copper on with one half of the cycle and remove it with the next.

Unsmoothed DC with a ripple will not really affect this, but the current draw will not be constant., not that it will matter particularly for your purposes. Feed the PSU onto a 12V battery for a more constant supply.

With regard to electric shocks, not with 12 V!. You'd have to chew the wires to even feel the slightest tingle.

If you are healthy you have a resistance of about 140 K ohms across from hand to hand, and 12 V won't push much current through that! Do not try this with higher voltages. You won't like 240V and it could prove fatal!

You might just feel a tingle at 50V.

DC is the more dangerous, since the voltage remains constant. At least AC passes through Zero, 50 or 60 times a second, giving you a chance to let go. 400 Hz as used on aircraft might be a different kettle of fish, so don't try it!

Howard

Chris V.