Back in the day with Carbon Steel cutting tools it was vital to keep the tool cool. Carbon-steel loses its hardness at surprisingly low temperatures, perhaps 180°C. The easiest way to keep Carbon-steel cool was to flood it with coolant. It was also found that lubricating the work improves finish. White emulsion is a mix of water – an excellent cheap absorber of heat – with an oil that does the lubricating. The flow of liquid tends to remove swarf, which left to get under the tool will ruin the finish. Cutting fluids may emphasise lubrication more than cooling, or improve both.

HSS stays hard up to about red-heat, but – worked hard – it too requires fierce cooling. In production, speed is often everything because stopping machines to swap out blunt tools can be a financial disaster.

Carbide is much sterner stuff than HSS, and its cooling needs – if any – are different. Splashing coolant on carbide is likely to crack it so either flood cool or not at all.

The material being cut matters. Most obviously Aluminium needs help – it tends to weld itself to tools, especially hot fast carbide. A bit of paraffin works wonders! Mild-steel is fairly soft, but other varieties are harder/tougher and need help. Work hardening stainless needs plenty of cutting fluid and aggressive cutting.

Much of the commercial advice about coolants is driven by the needs of high-volume production, not what goes on in a small workshop. In production a tool lasting 20% longer, with a 5% reduction in poor-finish rejects, and a 10% reduction in the electric bill make cooling and lubricating essential. Chaps making one-off's at quarter-speed wouldn't notice the difference.

Flood cooling with emulsion has many disadvantages. The original mixes used to 'go off', stink, and cause horrible infections when they got into a cut. (Before antibiotics!) Later formulations fixed that problem, but flood cooling is messy; the water can cause rusting, dumped down the drain the fluid is polluting, and the lubricant costly. The machine tools are modified to collect waste, and a system installed to recover clean lubricant. Not worth it in a small workshop.

Flood cooling is so obnoxious there are many alternatives. Mist systems are popular – these spray a measured dose of coolant direct on to the cutting point. The dose is carefully regulated so that the machine doesn't get wet. Mist systems are complicated to set-up and introduce a new health hazard – breathing the mist. So they too may need to be shielded or fitted with an extractor system. Expensive. Not many amateurs would need a mist system.

In the small sample of Machine centres I've read about, compressed air, Nitrogen or Argon is favoured. It's directed at the tool tip which it cools without thermally shocking the carbide and it blasts swarf away from the work and into into a collector. An interesting feature of these machines is how they manage the ton or so of swarf produced per shift. Conveyor belts… A key advantage of compressed gas cooling is that it's clean. The swarf is easier to handle, and being uncontaminated, has top recycling value.

In my workshop, for what it's worth, I use cutting fluid/coolant only:

- When drilling (CT90 sprayed or brushed to extend the life of the drill)

- When tapping (CT90 sprayed to reduce the chance of breaking the tap and to reduce the chance of tearing the thread, taps and dies)

- On Aluminium (to stop it sticking to the tool . Brushed or sprayed WD40, CT90 or paraffin, which is cheaper)

- When hacksawing by hand (CT90 Sprayed. Because I need all the help I can get with physical work and the blades last longer)

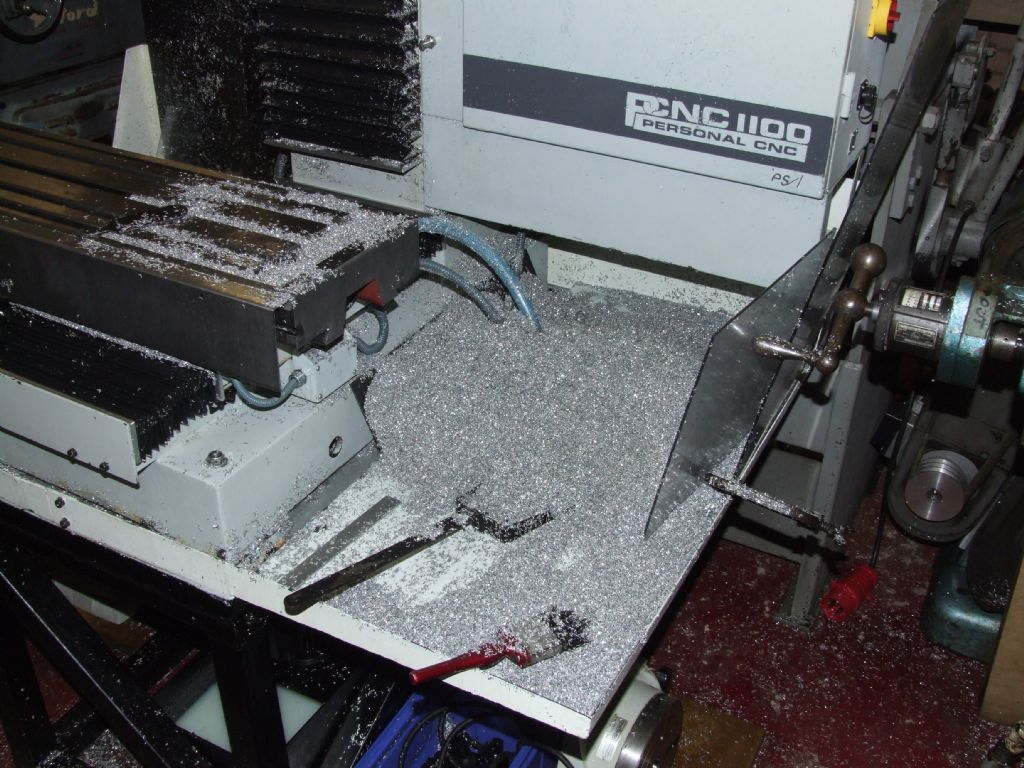

- Flood cooling on my mill only when roughing out a lot of steel. (To extend the life of my HSS cutters) I find flood cooling too messy to be worth the trouble on small jobs. I flood with neat cutting oil due to a prejudice against water based emulsions which I fear might cause rust. With little reason!

- When the finish is important and applying cutting fluid improves it. ( I mostly use carbide, and good finish is often best achieved by taking deeper cuts. My modest lathe isn't ideal for carbide, so when needs must HSS and lubricant are good alternatives.)

I use CT90 because my local has it on the shelf, not because I've tried anything else. Other potions available!

Dave

Edited By SillyOldDuffer on 07/06/2019 10:31:11

Nigel Graham 2.