I though (following Howard's advice among others) that I would approach this in a systematic way. Management summary: I'm still confused!

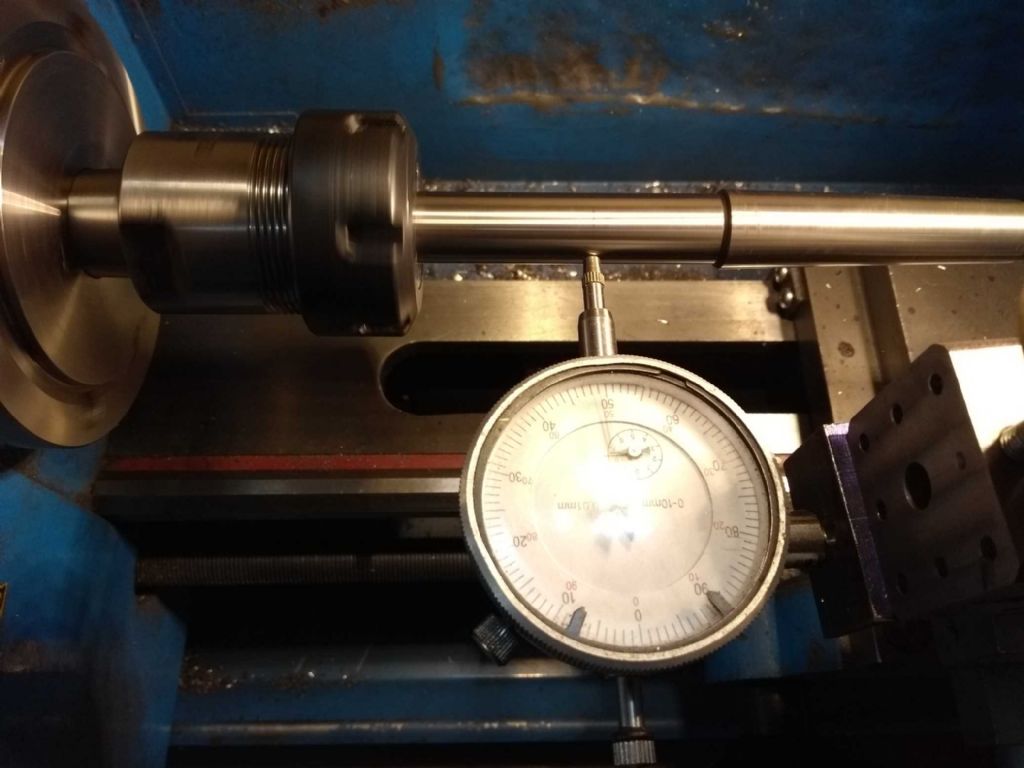

First I took an MT3 test bar and clocked the wobble.

I took most of my measurements 110 mm from the face of the spindle.

I'm going to use the term wobble to describe what I'm measuring. I'm not entirely sure I understand what run-out is – is it wobble (item at an angle to the spindle axis) or offset (item in line with axis bit not on centre). Accordingly, I will use an informal term so I don't get flamed

The wobble was of the order of 0.02mm. Hard to tell for sure as there was a definite tick which I think is a problem on the surface. However, under a thou seems reasonable..

This shows that the spindle is accurate and that there is no much in the spindle bore.

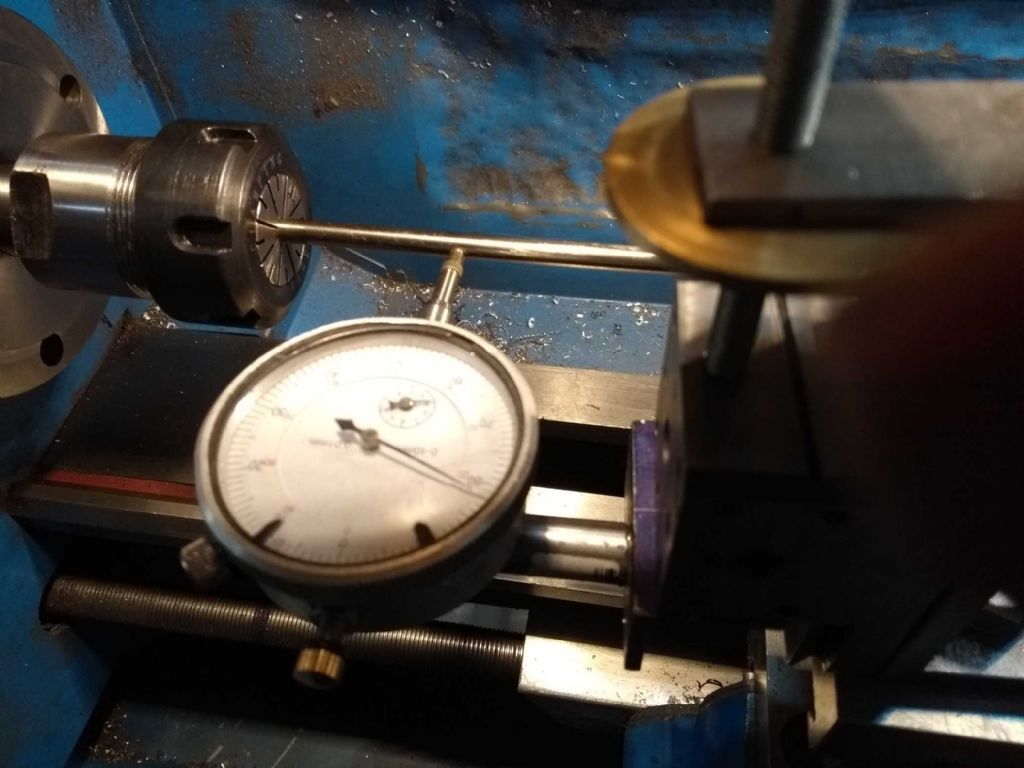

Next I measured the wobble in the chuck taper.

This came to around 0.06mm at three locations inside the bore. I measured again after re-seating and got a little bit less (around 0.05mm). I didn't try and see if the near points down the bar were in line (offset) or out of line (wobble). I've only just thought of it!

Having established that the chuck isn't crackingly good, I thought I'd measure some test bars in collets.

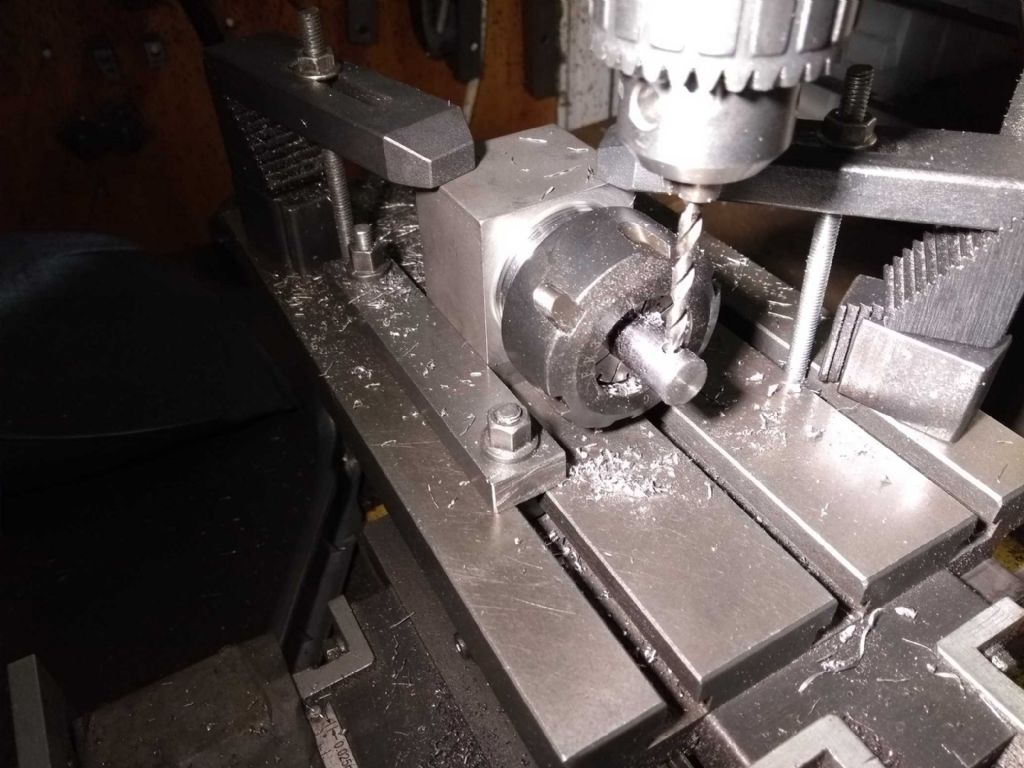

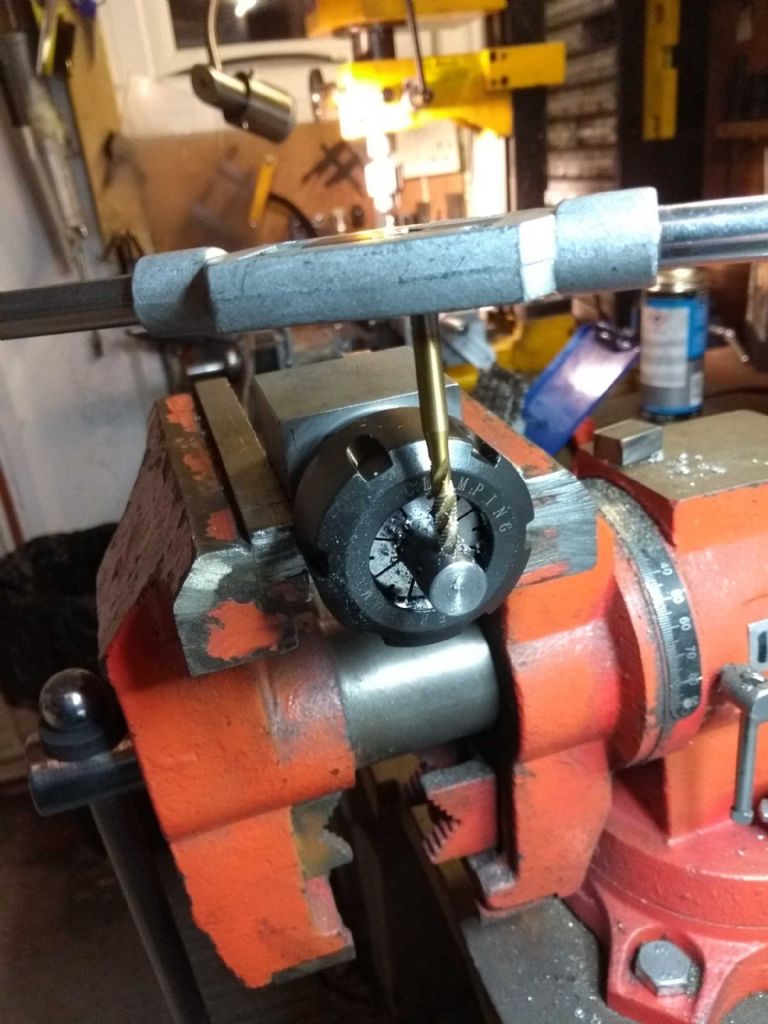

First up was an MT2 test bar held in a 16mm collet. Before trying this I attempted to deburr the collet. I took a small square diamond fine and run a a few passes on the insides and outsides of all the cuts. next I took a pick and pulled along the cuts to drag and swarf out. then finished off with a clean with WD14 and a rag. I should say that there was no evidence of buts by feel before hand.

And this was the test bar mounted in the collet.

I got wobble of 0.17mm at 75mm from the spindle face, 0.25 at 110mm and 0.36mm at 135mm. The wobble was entirely visible.

Next some 12mm silver steel. this was noticeably better -and better than the readings I'd taken before.

75mm – 0.06, 110 – 0.10 and 135- 0.14.

Next some 6mm scanner bar – like the bars in printers these should be ground and accurate.

at 110 mm I got 0.21mm wobble.

Finally, I took a piece of 20mm silver steel original intended for a crank, and did a few more things with it.

With the collet straight out of the box (first time of use), but cleaned:

0.30 mm at 110mm. Next I turned the rod in the collet (or possibly the collet in the chuck). This gave me 0.11mm wobble.at 110 mm.

I took the collet out and deburred as above and tried again. this time I got 0.24mm wobble at 110mm.

I tried again to rotate.(through 180 degrees) and got a wobble which was much less (0.07!).

As far as I can tell the low point of the wobble is the same with respect to the chuck / spindle regardless of the orientation of the collet or bar.

My best guess is that both the chuck and the collets are bad, so if the bad aligns, it's very bad, if it doesn't then not so much. This is not a nice thought and it doesn't seem realistic that all the collets are bad in a comparable way.

Any other ideas or diagnostics most welcome!

Iain

Grizzly bear.

![wp_20190722_005[1].jpg wp_20190722_005[1].jpg](/wp-content/uploads/sites/4/images/member_albums/162324/835182.jpg)