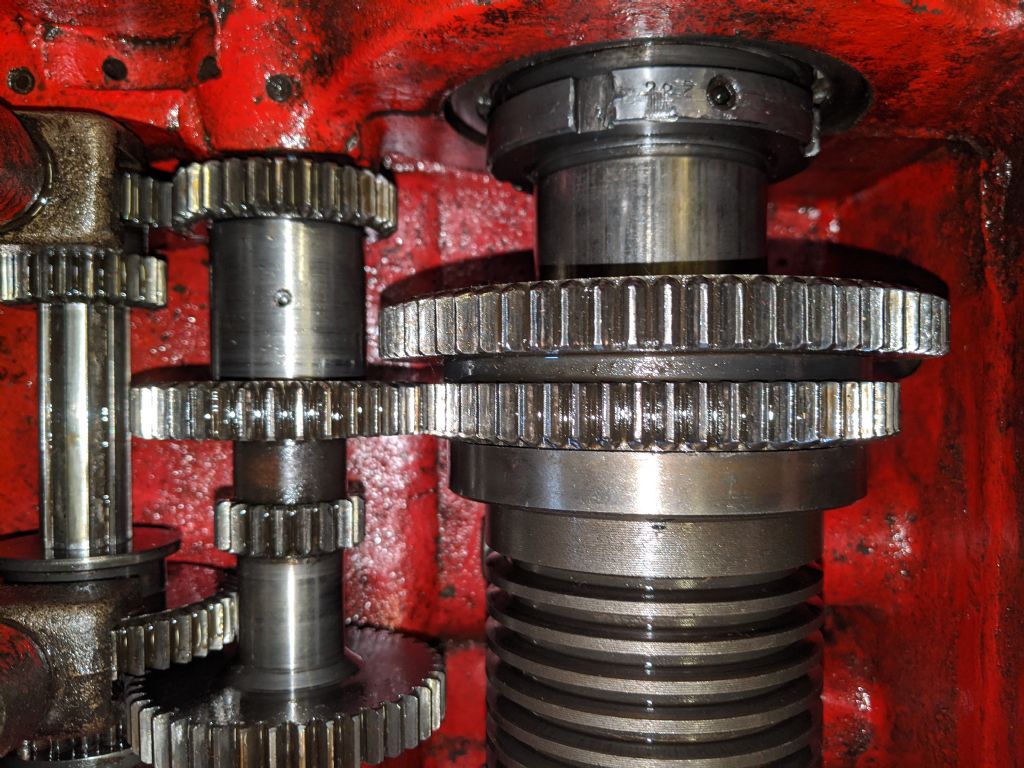

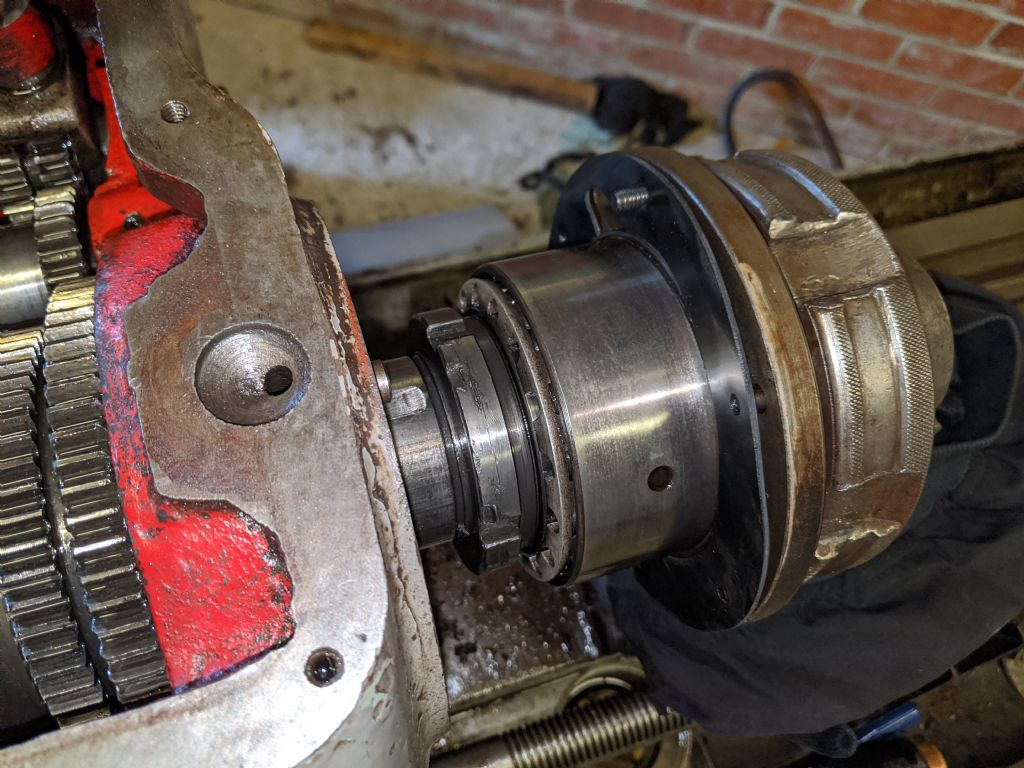

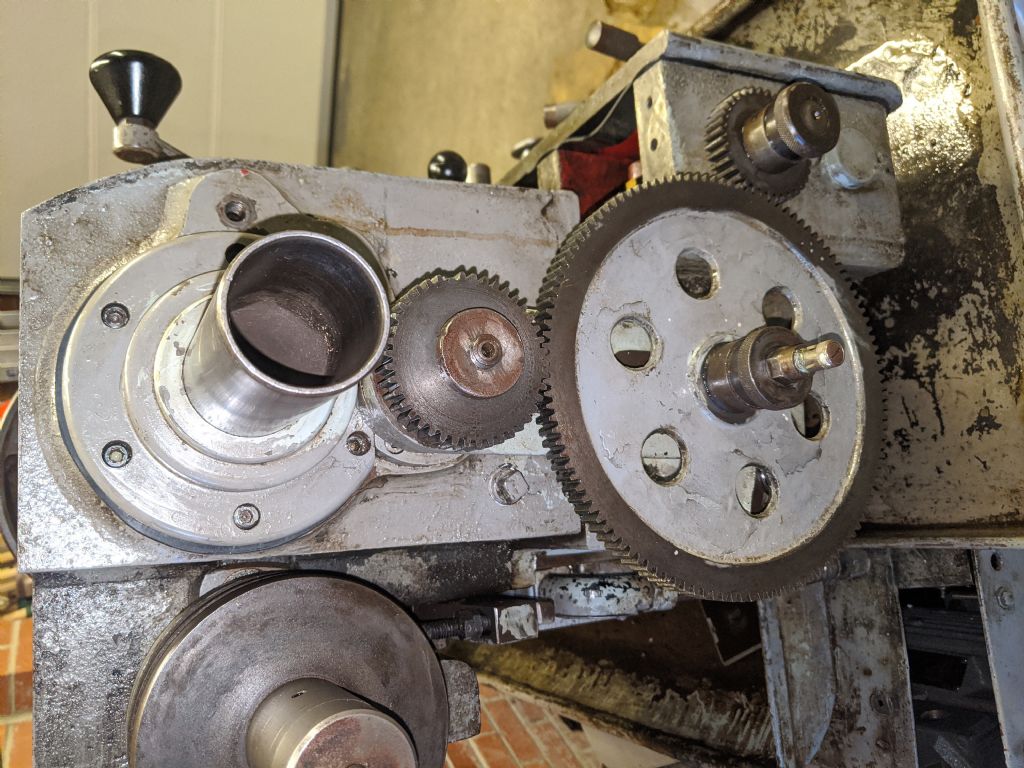

As the spindle is tapped back, using a copper mallet or block of wood and such things to not damage the spindle nose, put in the rear bearing as this will help align the shaft and make sure it is going in square. This helps it go in much easier

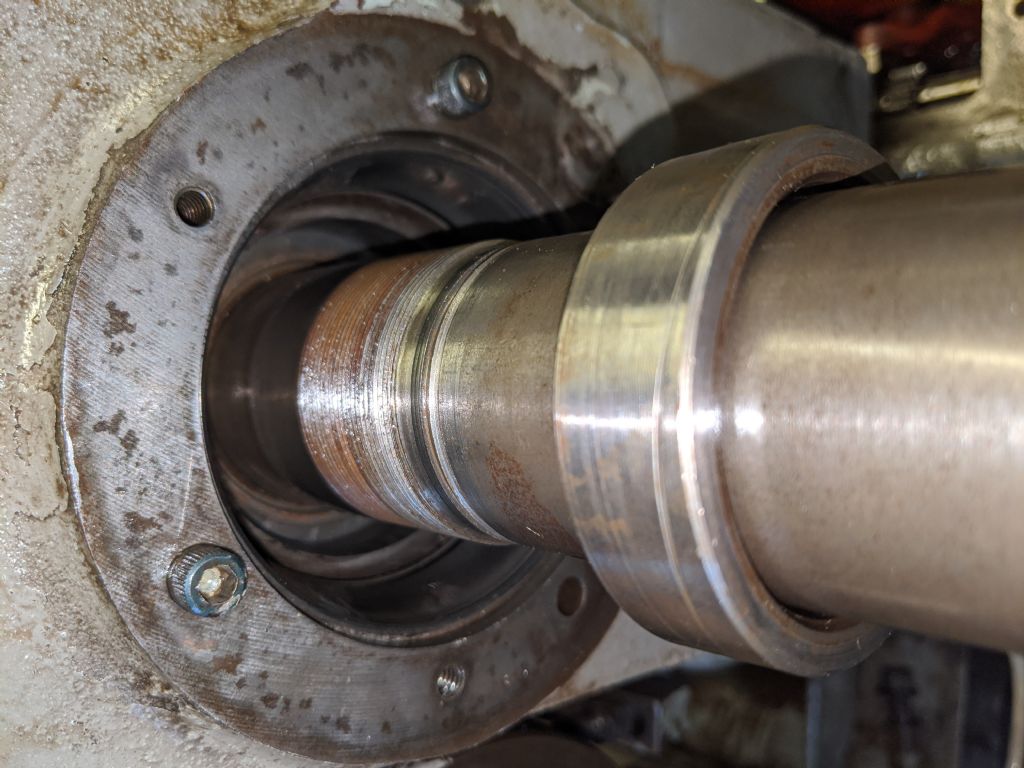

Once the spindle is back in place, you must put all the bolts in, lining up the gasket at the same time. I made my gasket tight over the bolts so that it would stay in place and aligned while I tapped the spindle back in

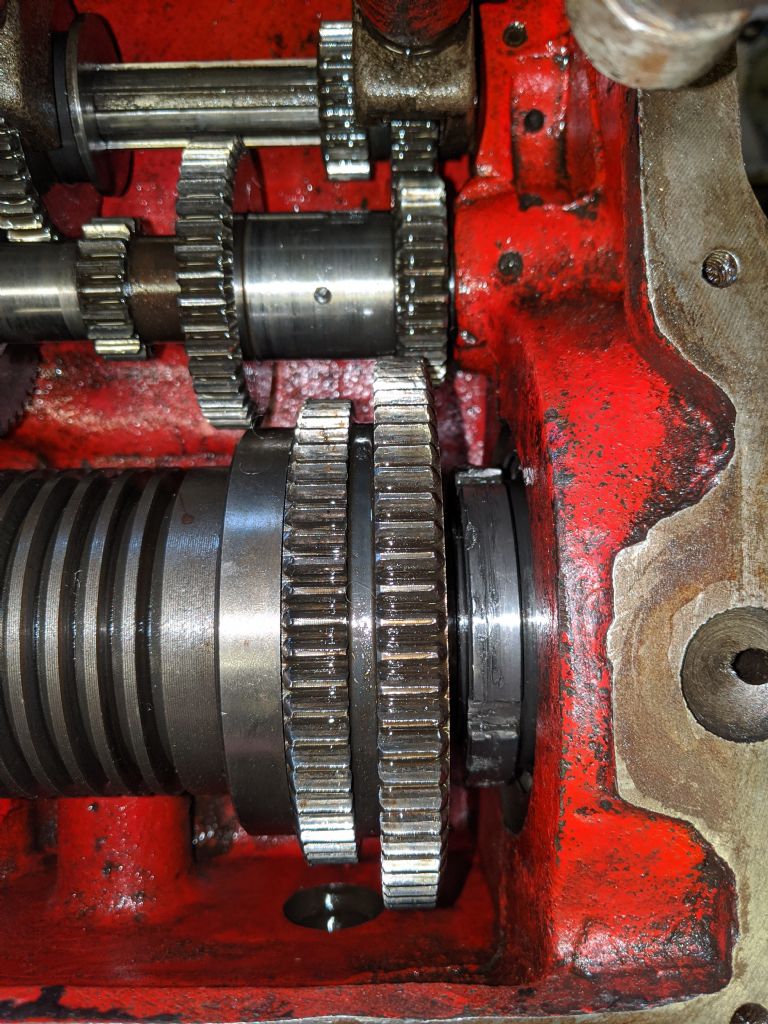

Then you can slide the spacer ring back on that I was on about earlier. If you put the bearing back in to align the shaft then this must be removed before you can do this.

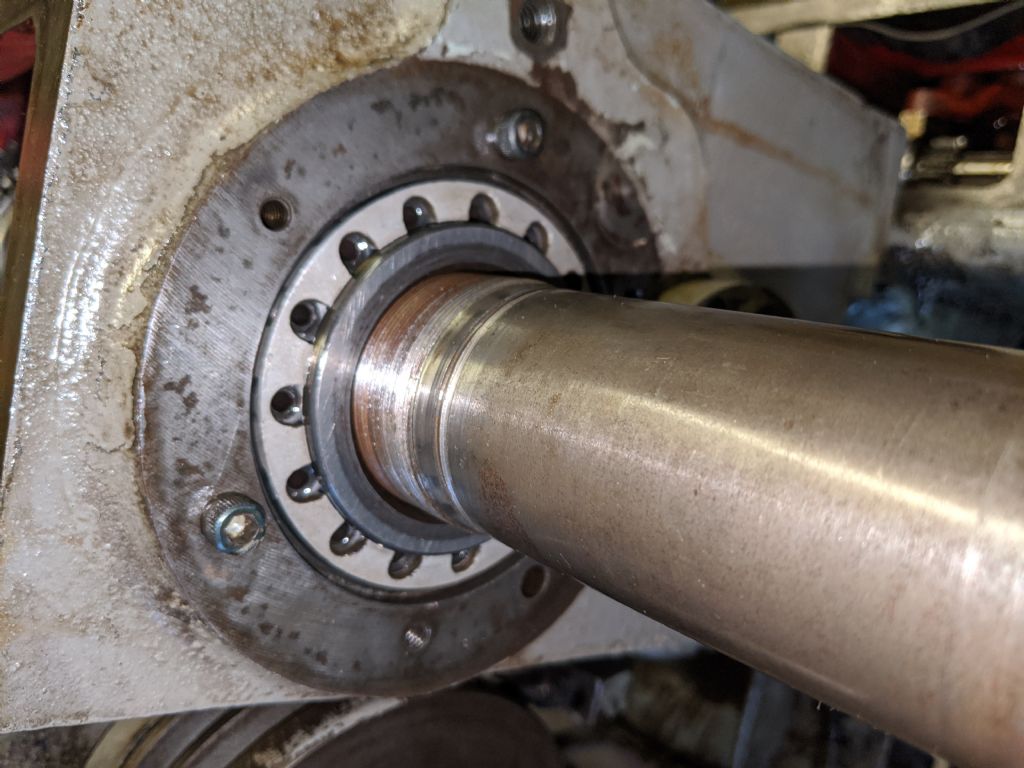

Then the bearing goes back in

Then the locking ring, making sure to tighten it down quite tightly

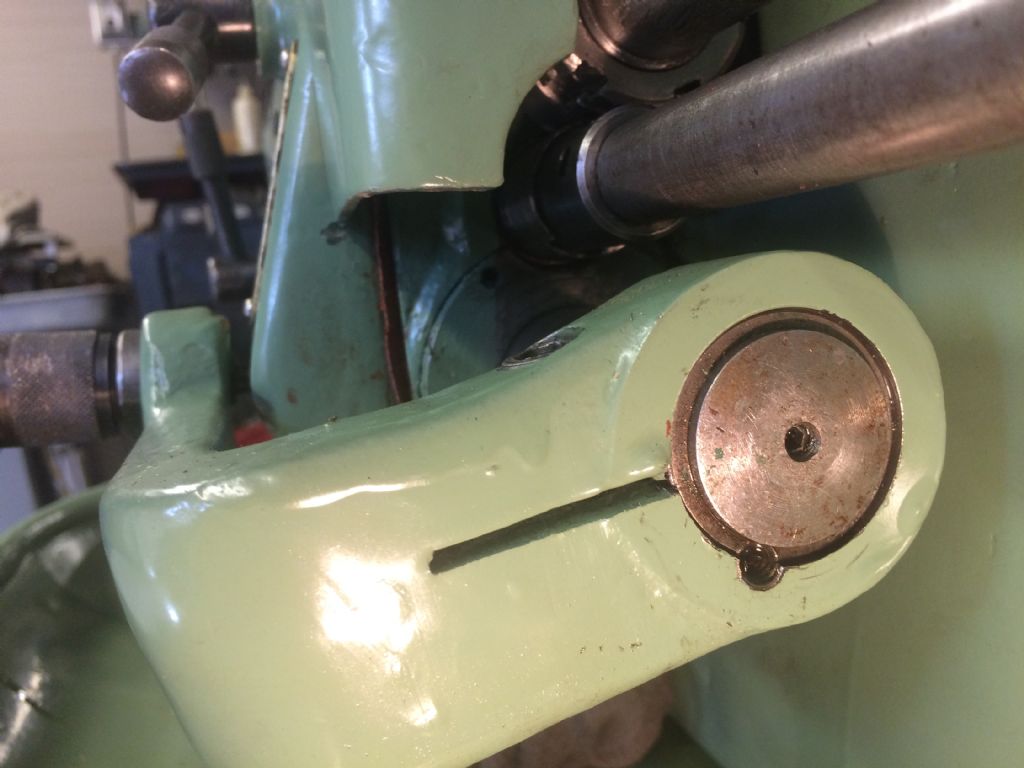

Then I put my gasket and end cover back on.

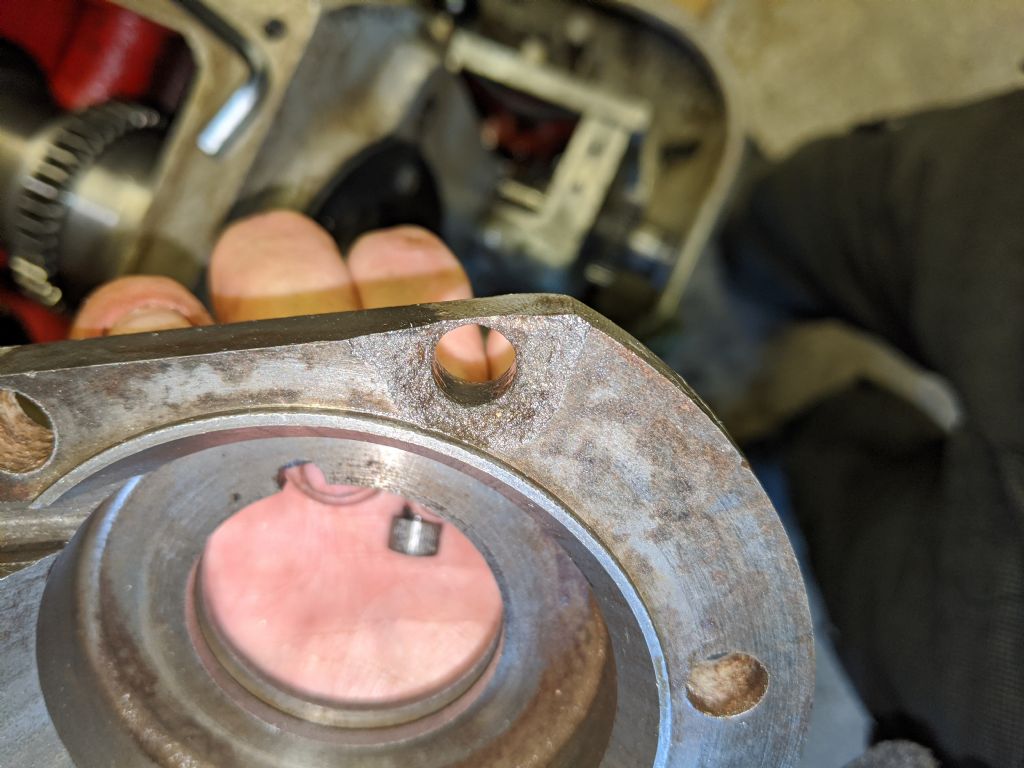

I realized as I was doing this that it wasn't going on square, so I took it off and had a look.

I knew the casting was broken, but I thought it was broken on one of the through-holes. Turns out it had broken in one of the recessed holes, making it a through-hole, so this piece is only being secured by two bolts. Not ideal, but it will do for now. I'm still trying to get spare parts from Tracy so hopefully, that'll come too.

This means it's not applying lots of pressure to the gasket all the way around, so it may leak there, but I tried to tighten the other bolts up enough to put a bit of pressure on it. Hopefully, it'll work.

So, it's all back together, I can continue to work on cleaning it up. I've put some PTFE tape around the plugs so they won't leak anymore either.

I have more than enough gasket material to make at least another 20 sets of gaskets, so I'm going to replace the one from the headstock too.

Phil, If you want any nitrile rubber to replace any of your gaskets with, I'd be happy to send you some since I have so much spare. I know you've done them already but may as well offer. It makes me think of the ridiculous profit margin on the precut gaskets on eBay. 35 quid for that is stupid. But I suppose some people will pay!

I'm very pleased with today's progress. I'm still going to go back out and get it fully reassembled though. Maybe even continue cleaning the other parts!

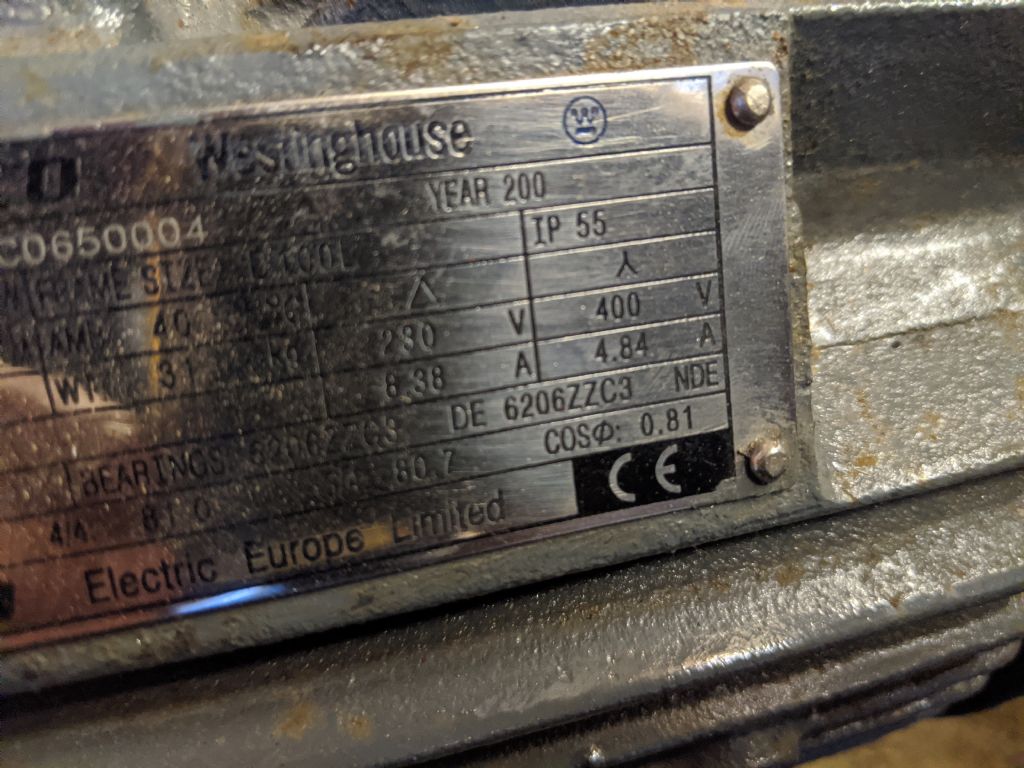

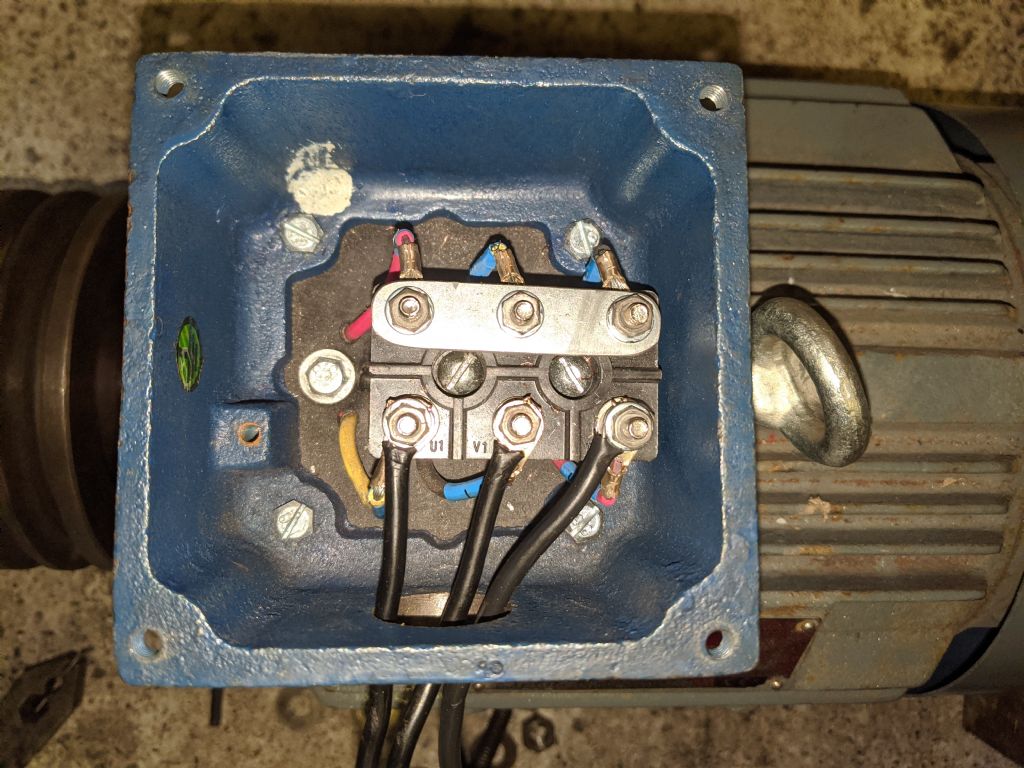

Not too sure how the motor will be running. Is it simpler to just spend the 25 quid on the transformer and wire that up?

Phil Whitley.