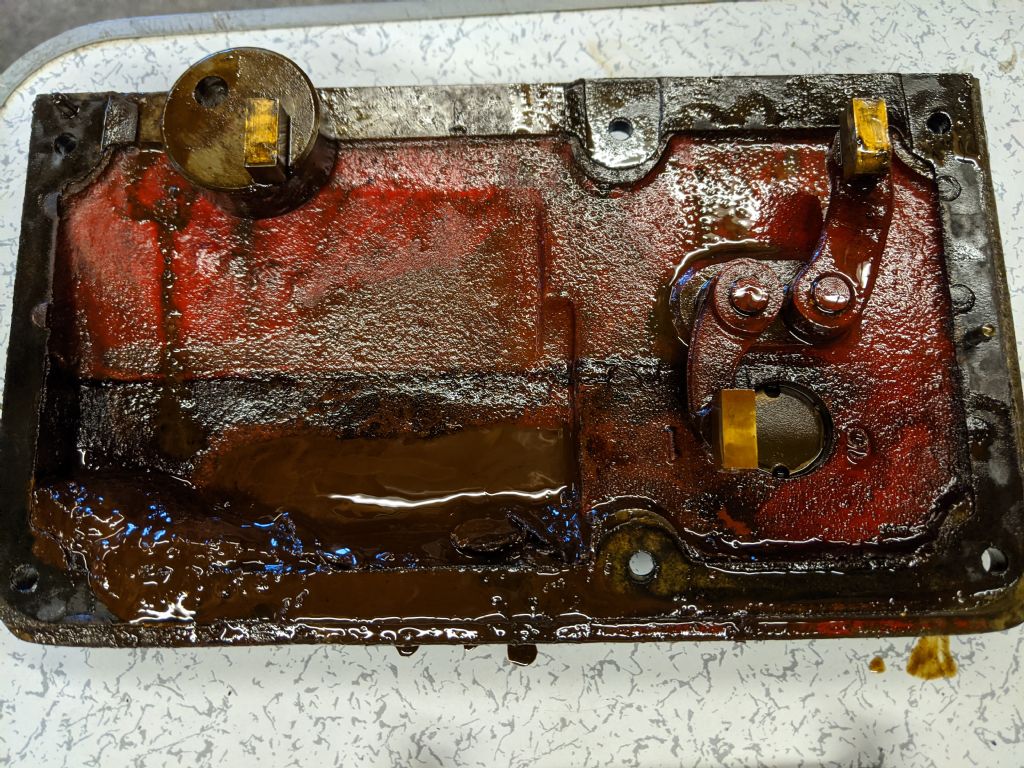

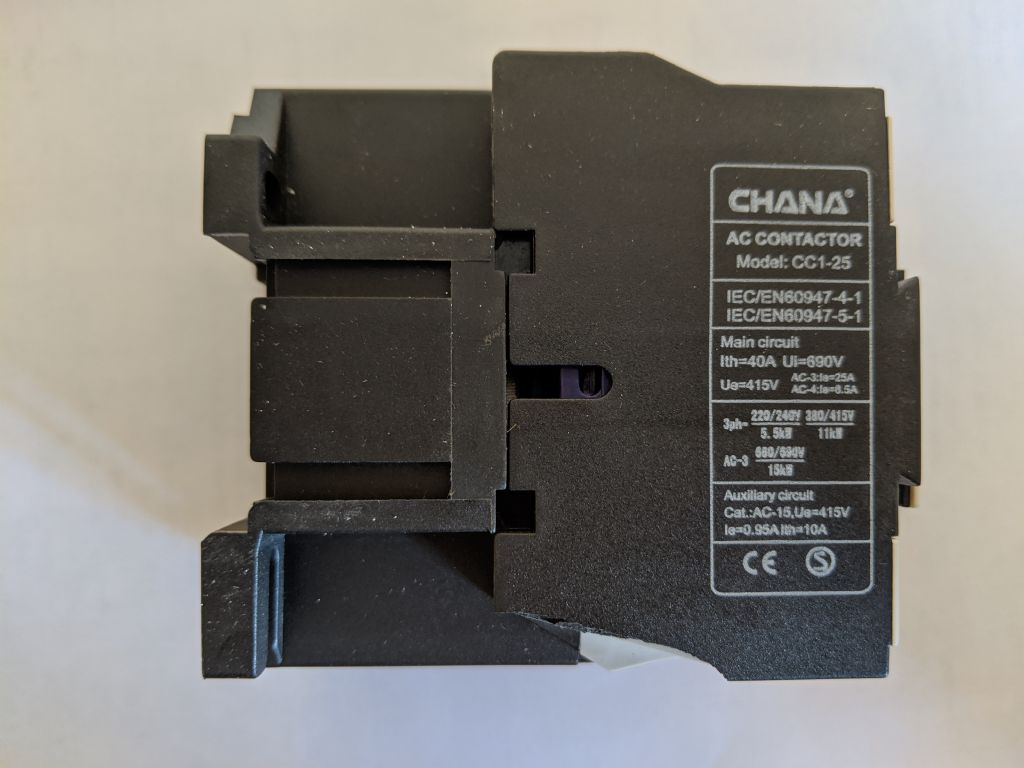

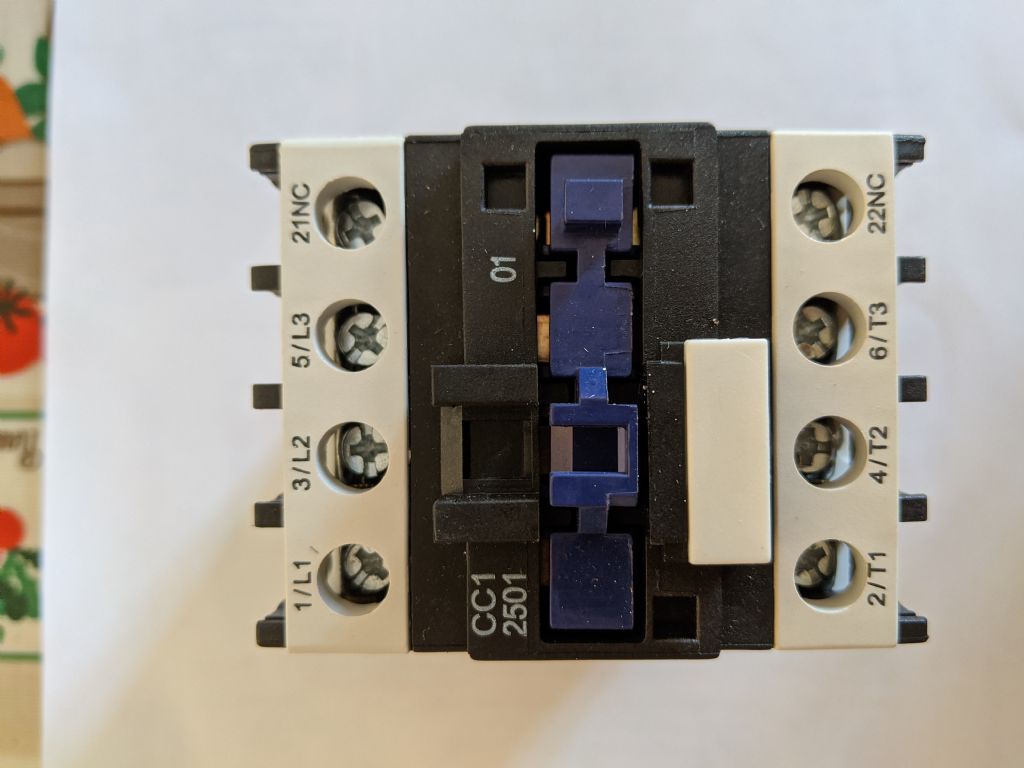

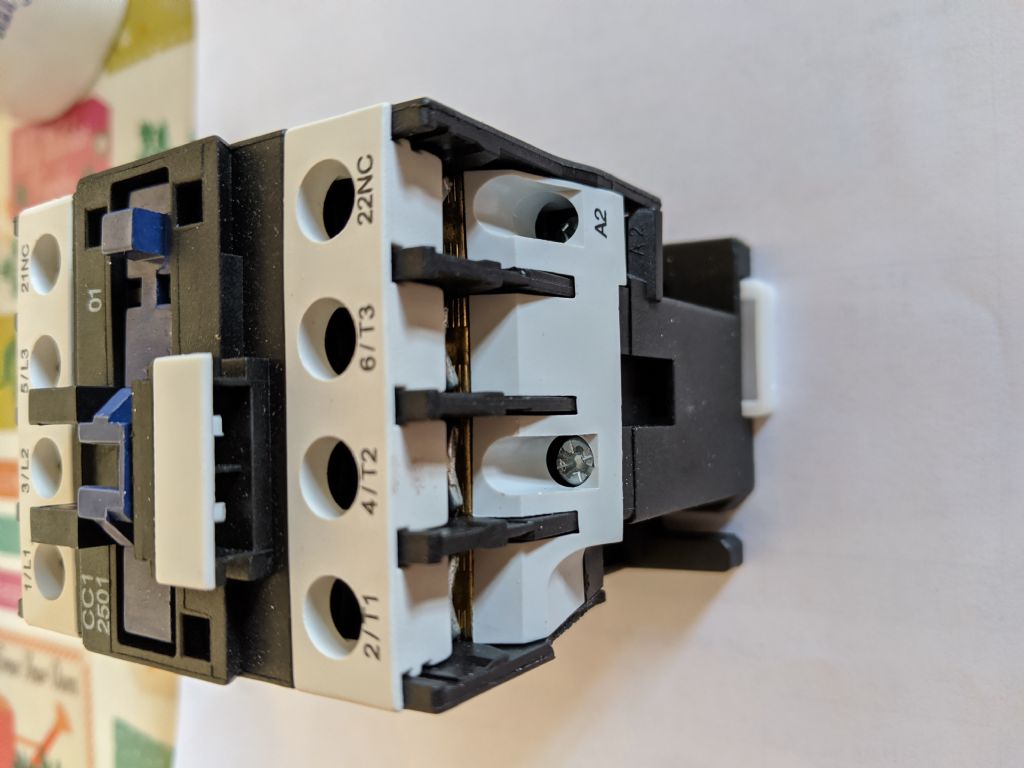

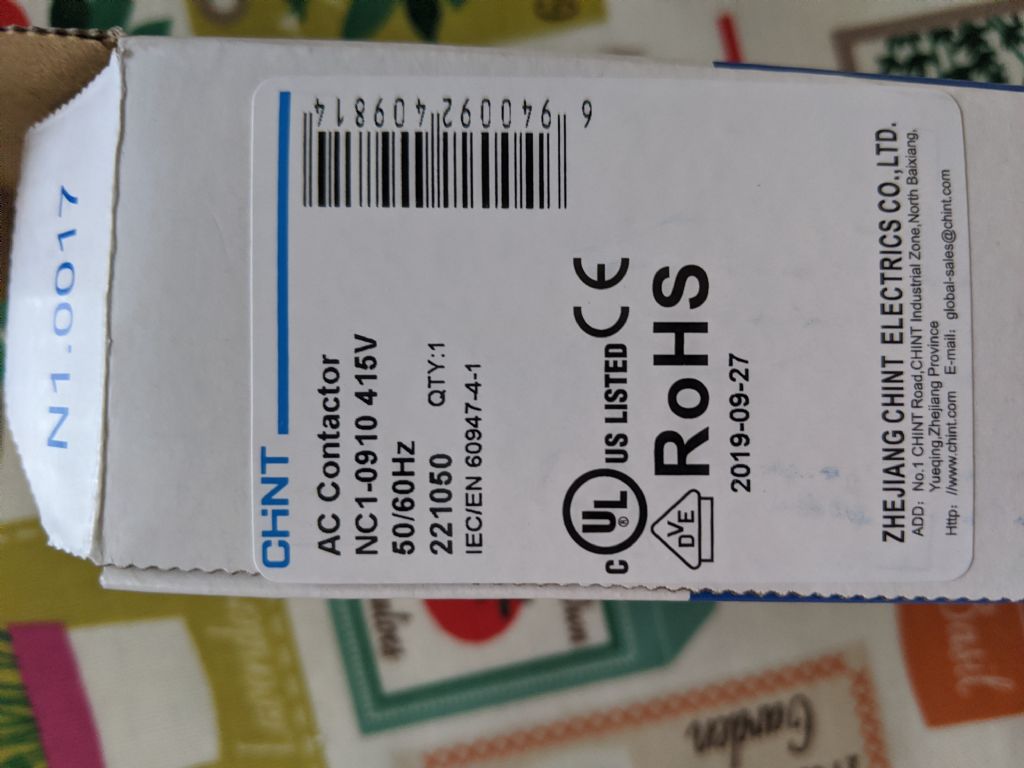

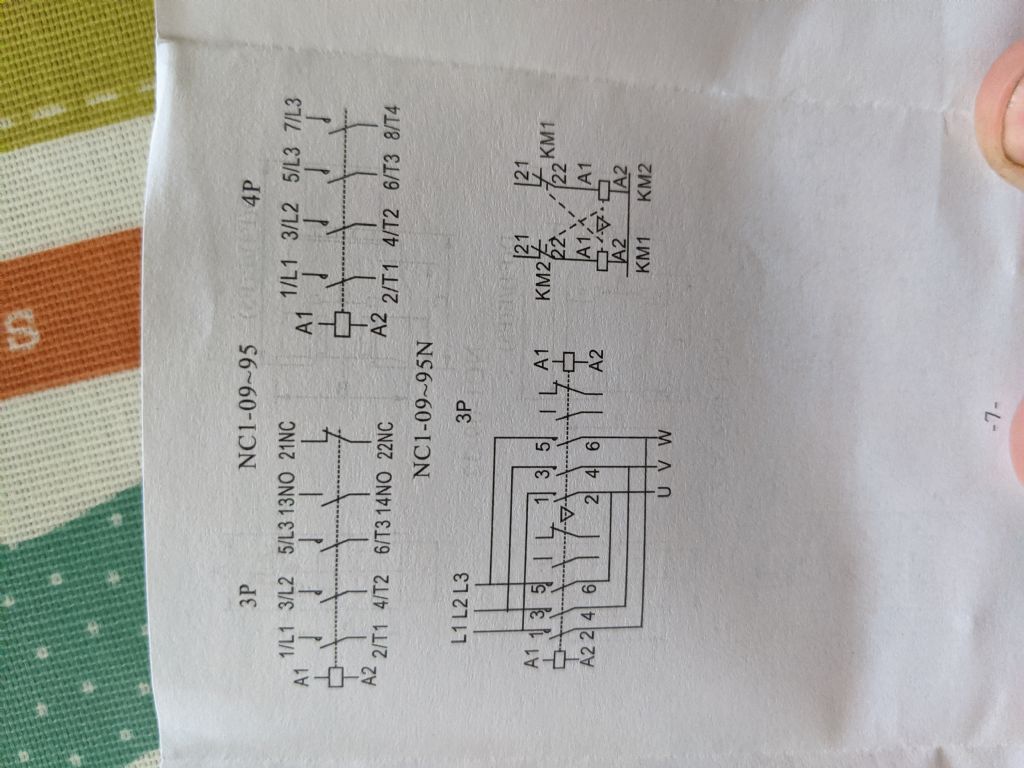

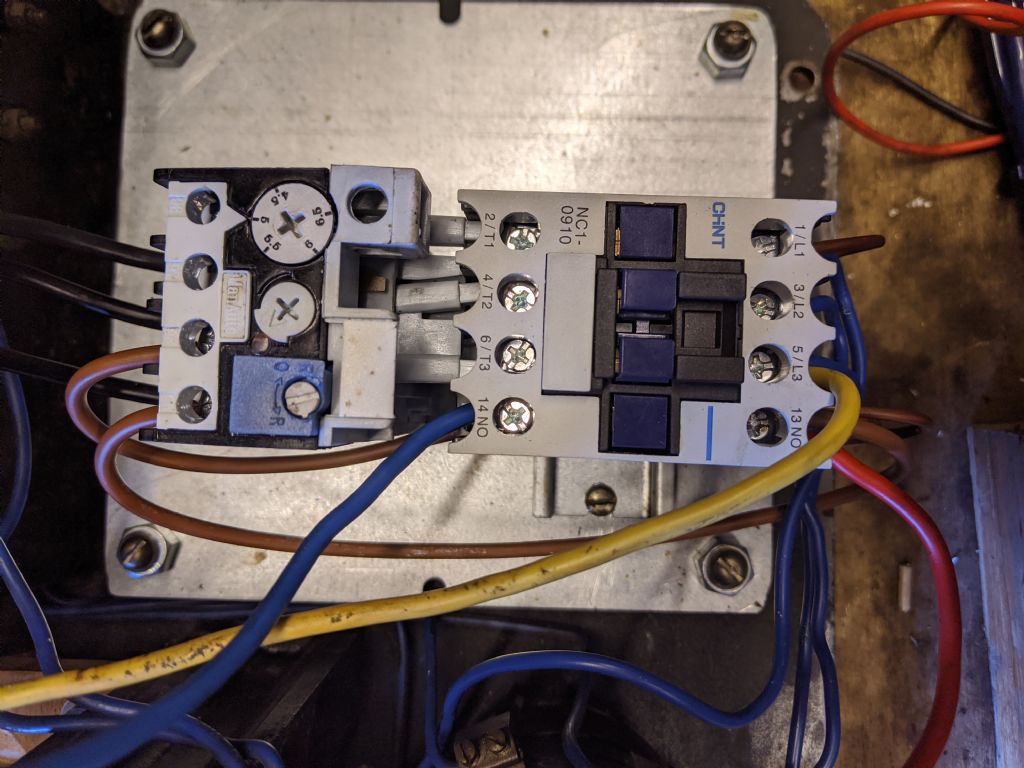

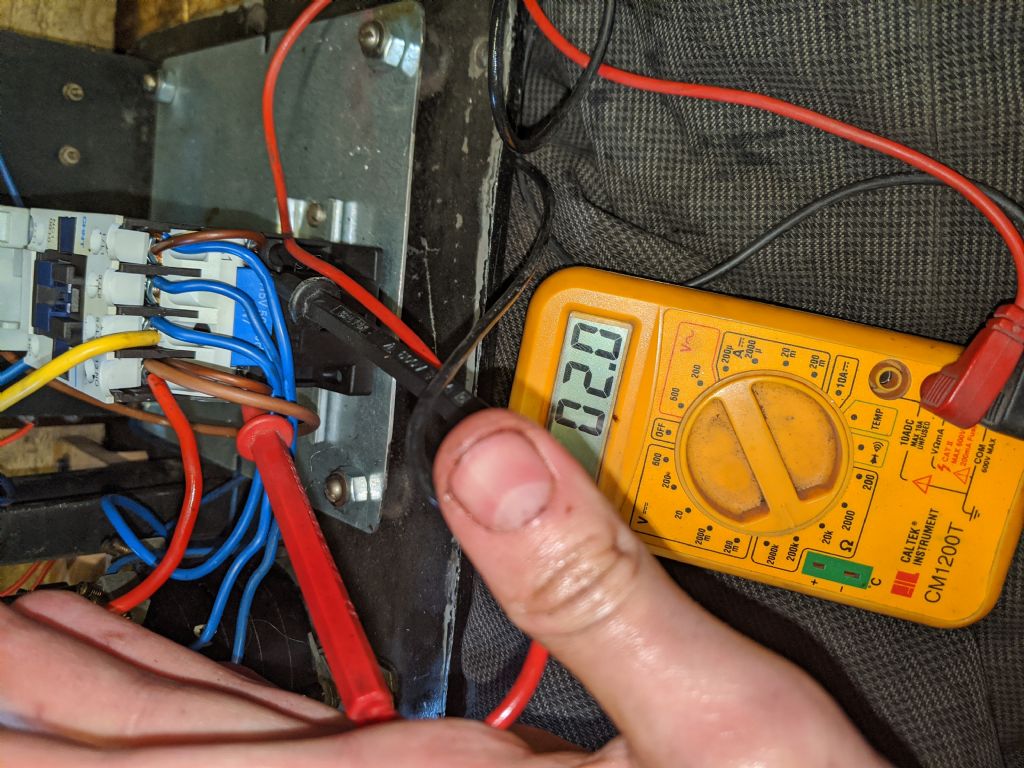

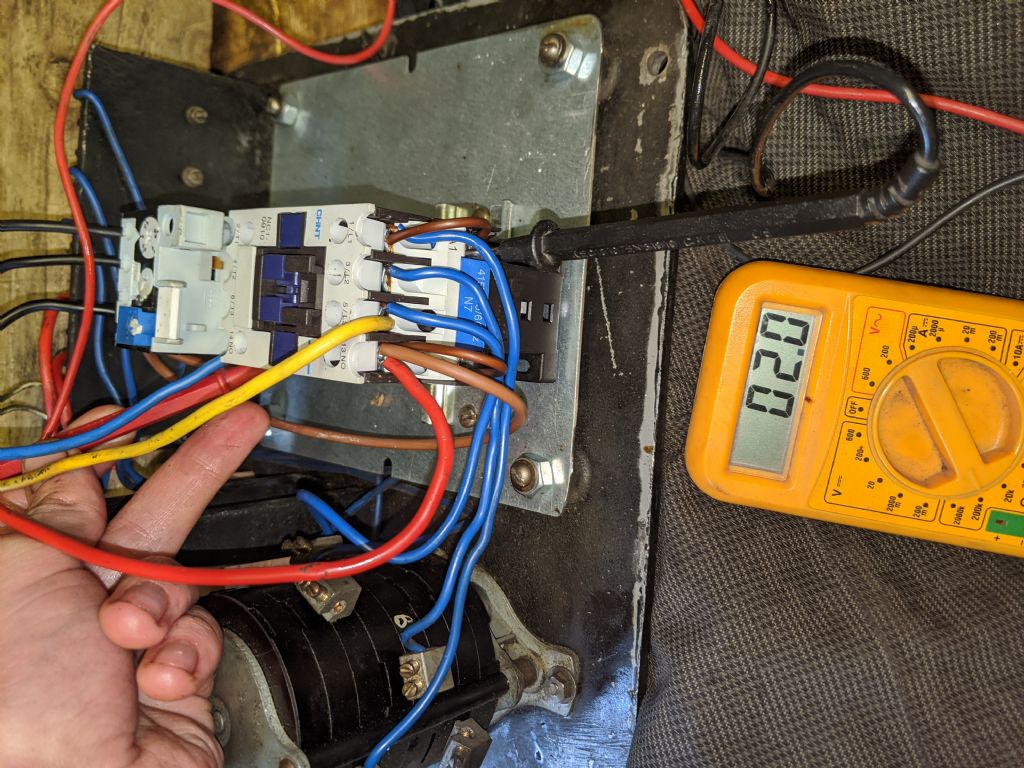

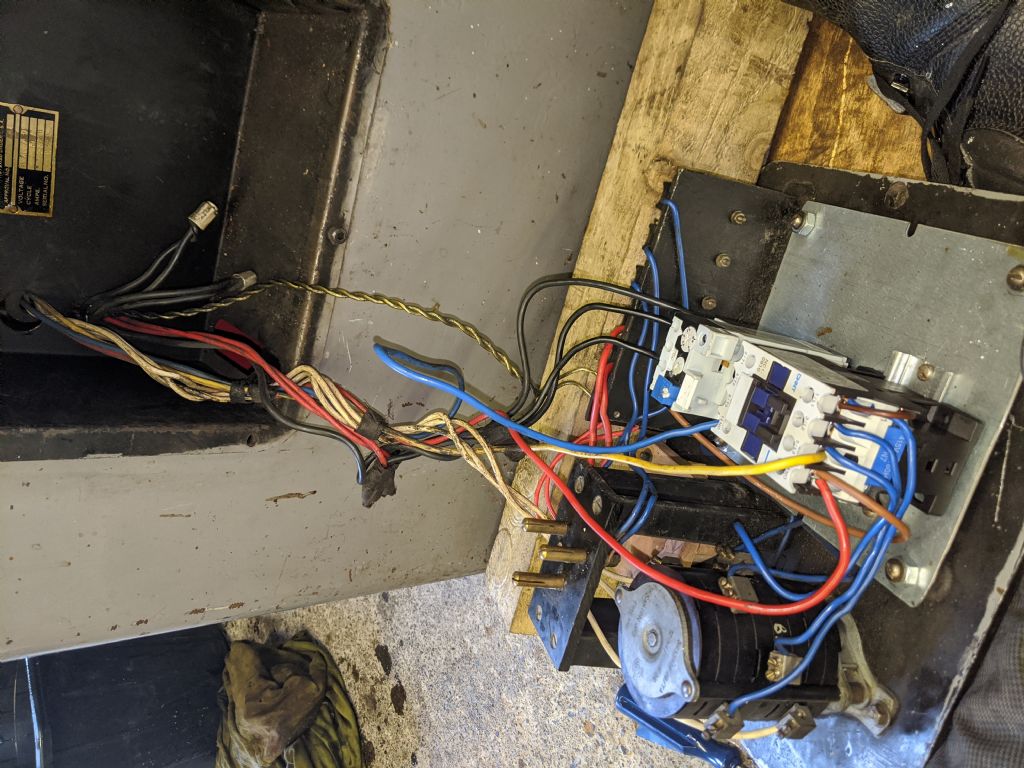

Hi Richard, First off, I am confused!! the terminals 21 &22 should read NO, not NC, but I am hoping this is due to chinese confusion in terminology. put a multimeter across them, there should be no connection until you push the contactor down, if this is the case, they are NO, and have been labeled incorrectly.

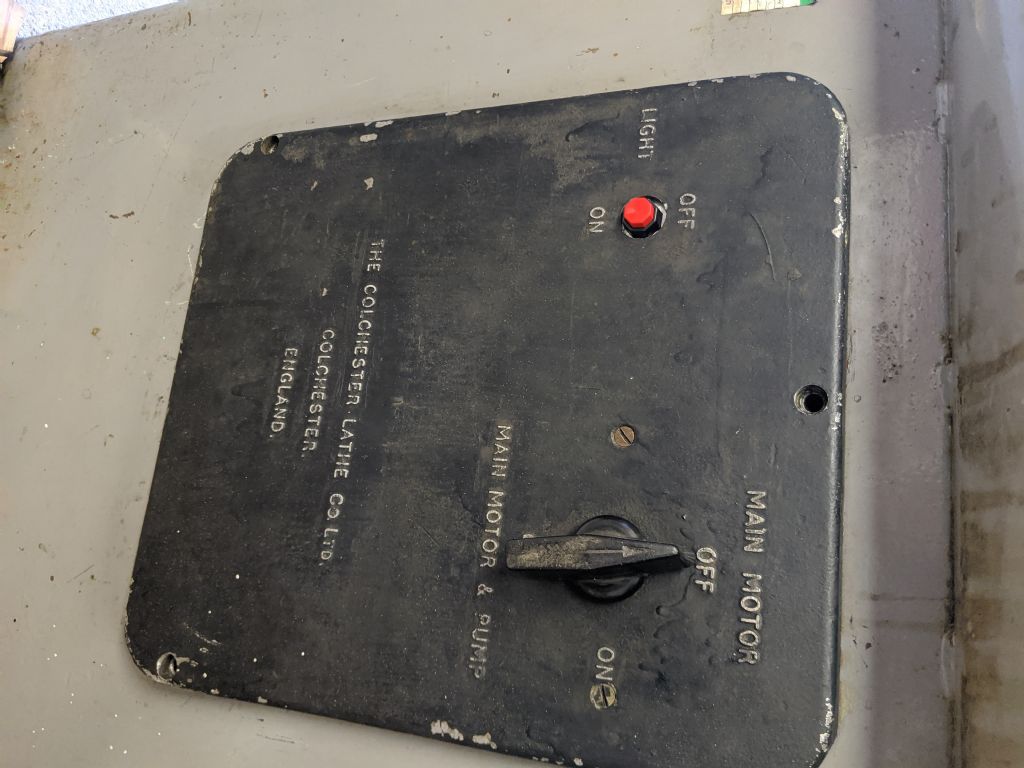

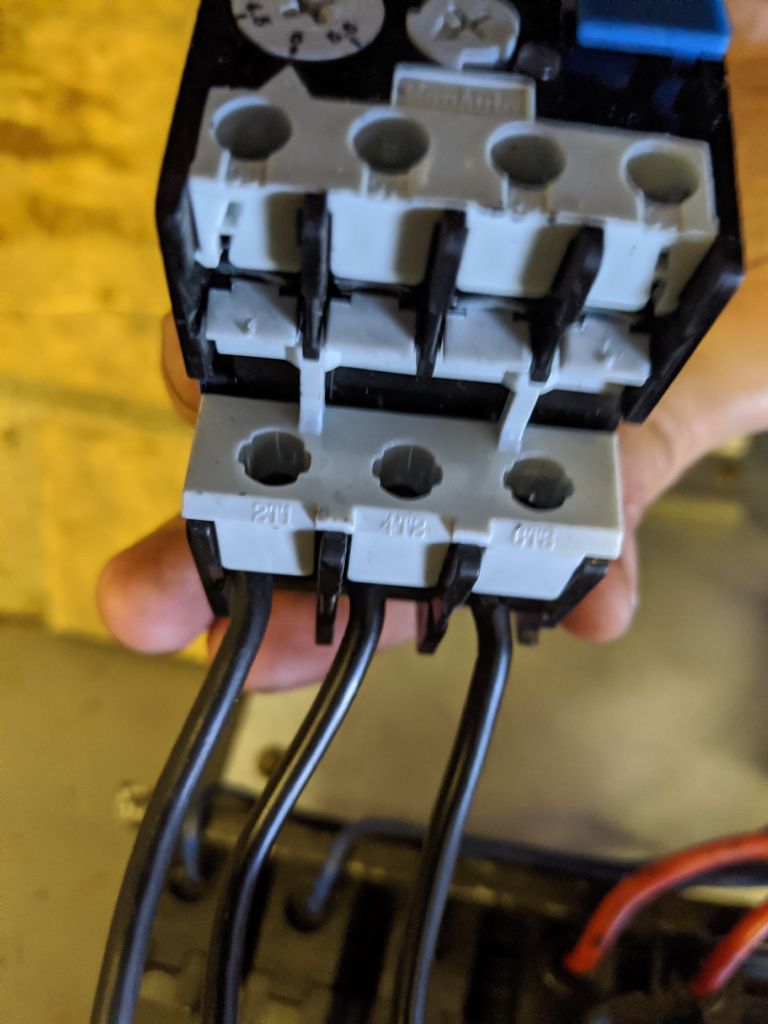

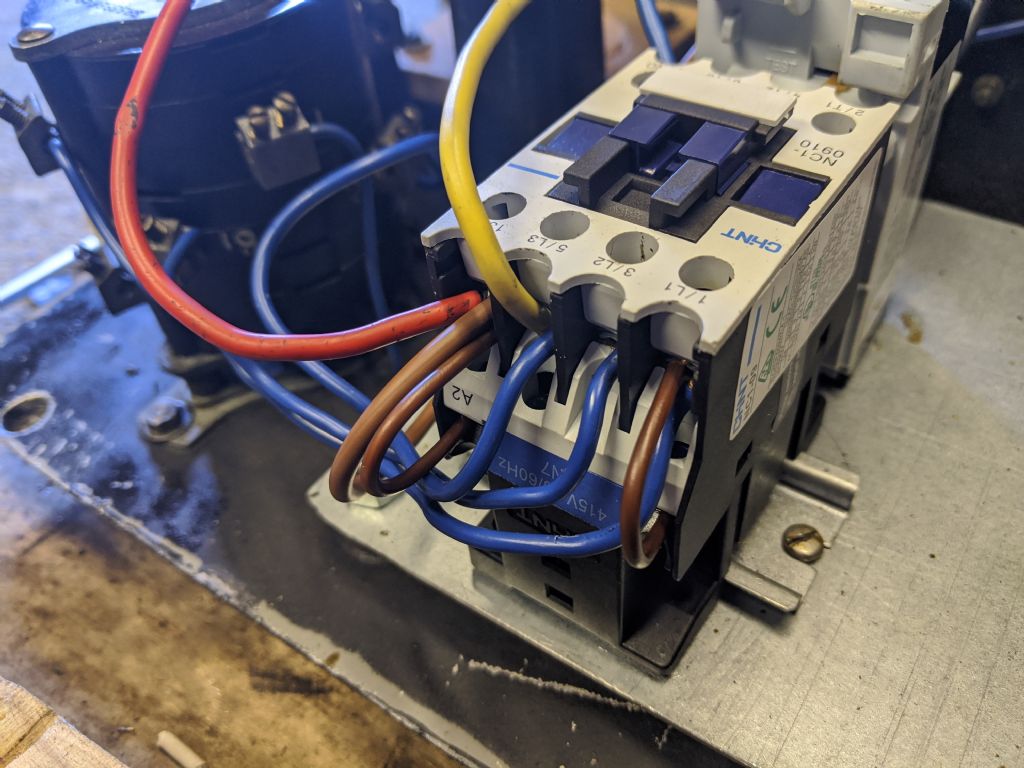

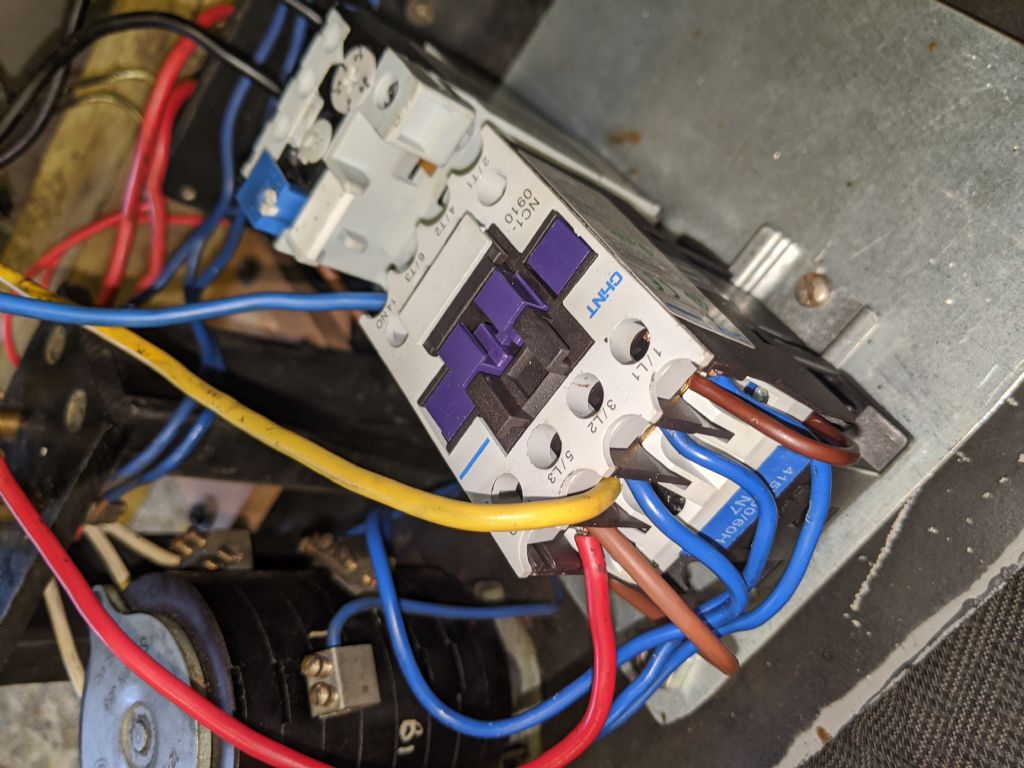

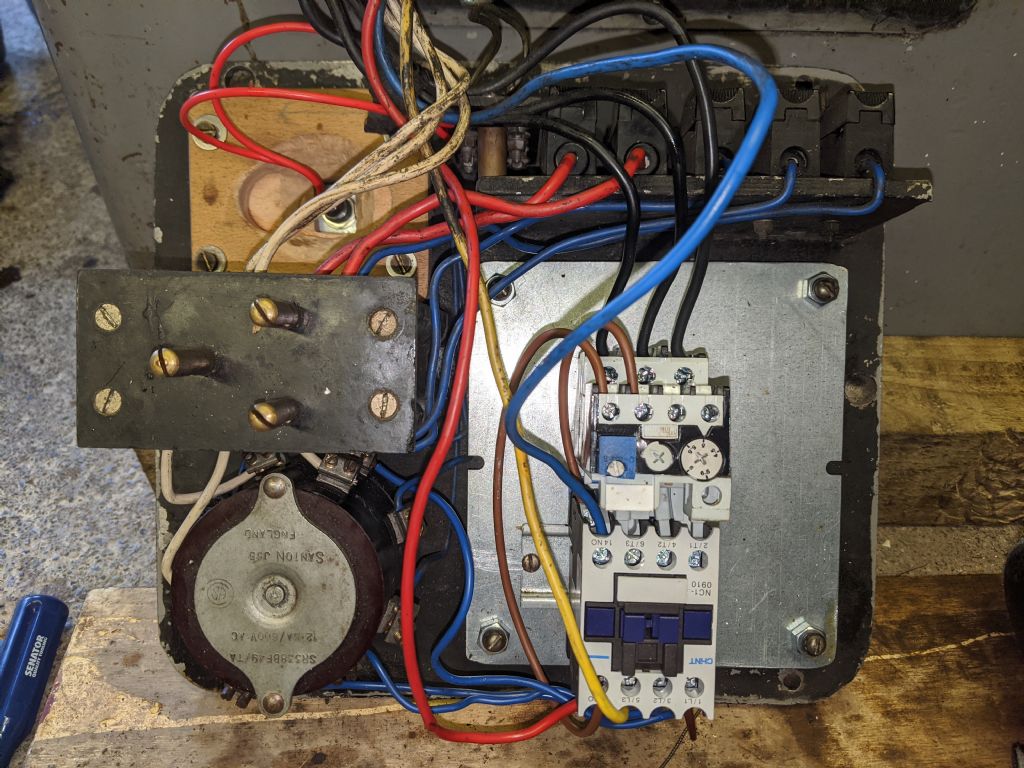

Connect the incoming three phases from the rotary switch to L1 L2 and L3 fit the overload to the contactor to T1 T2 and T3, connect the motor wires to the three outputs from the overload

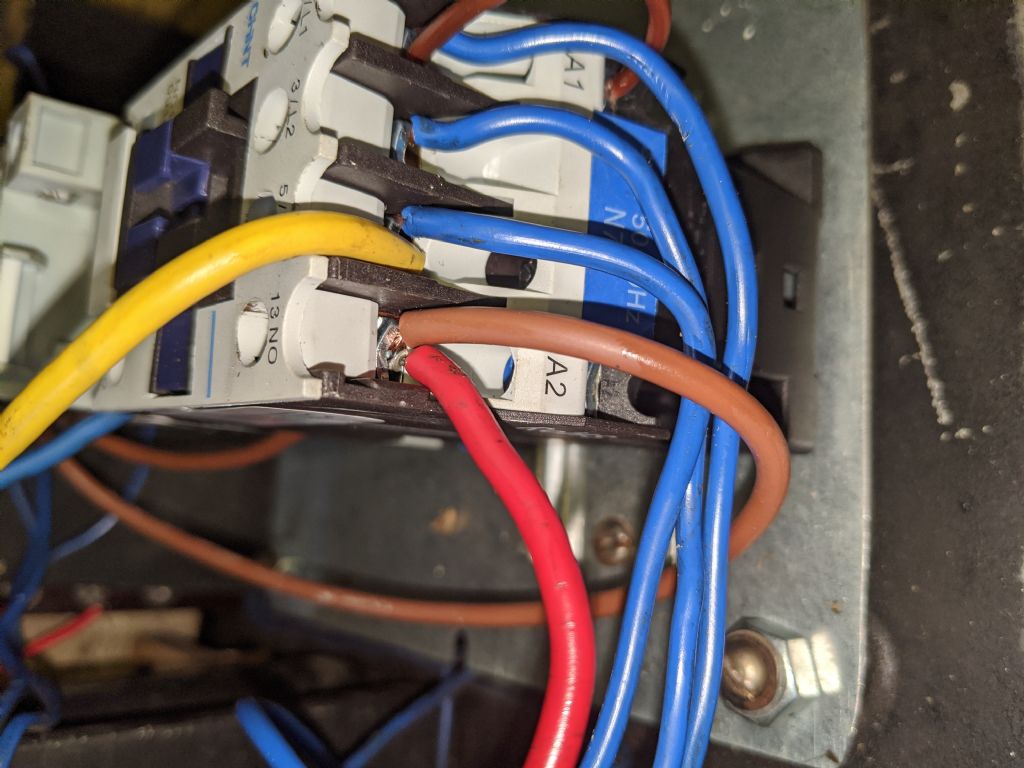

on the contactor, put a wire link betweenA1 (coil connection) and L1.

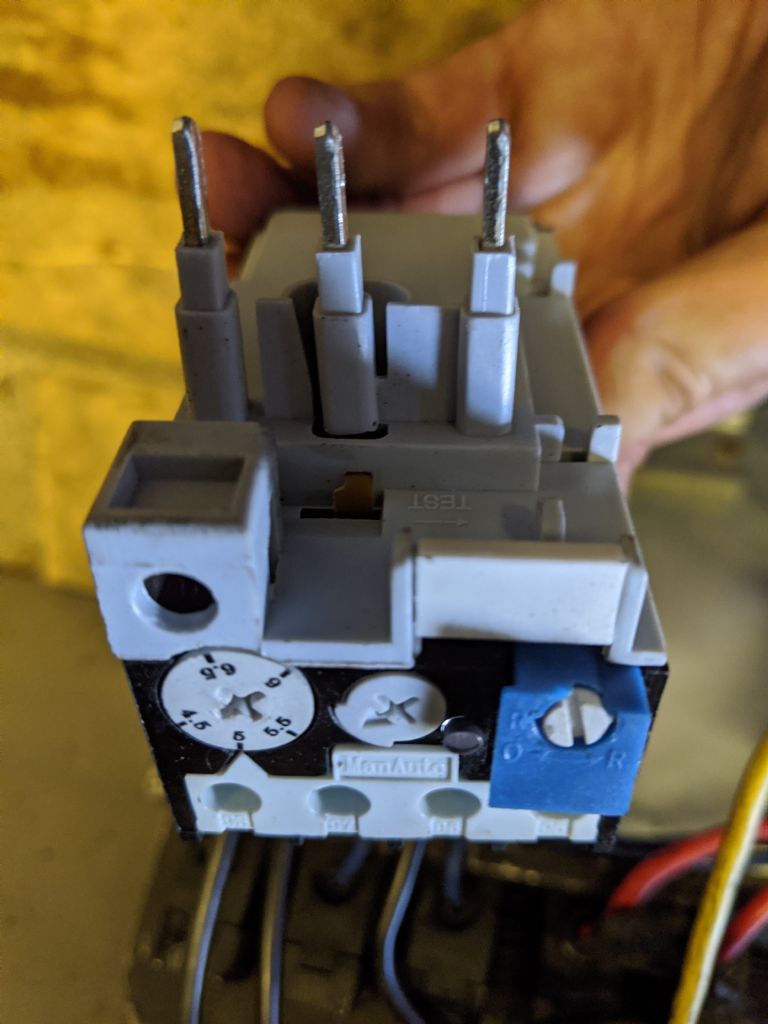

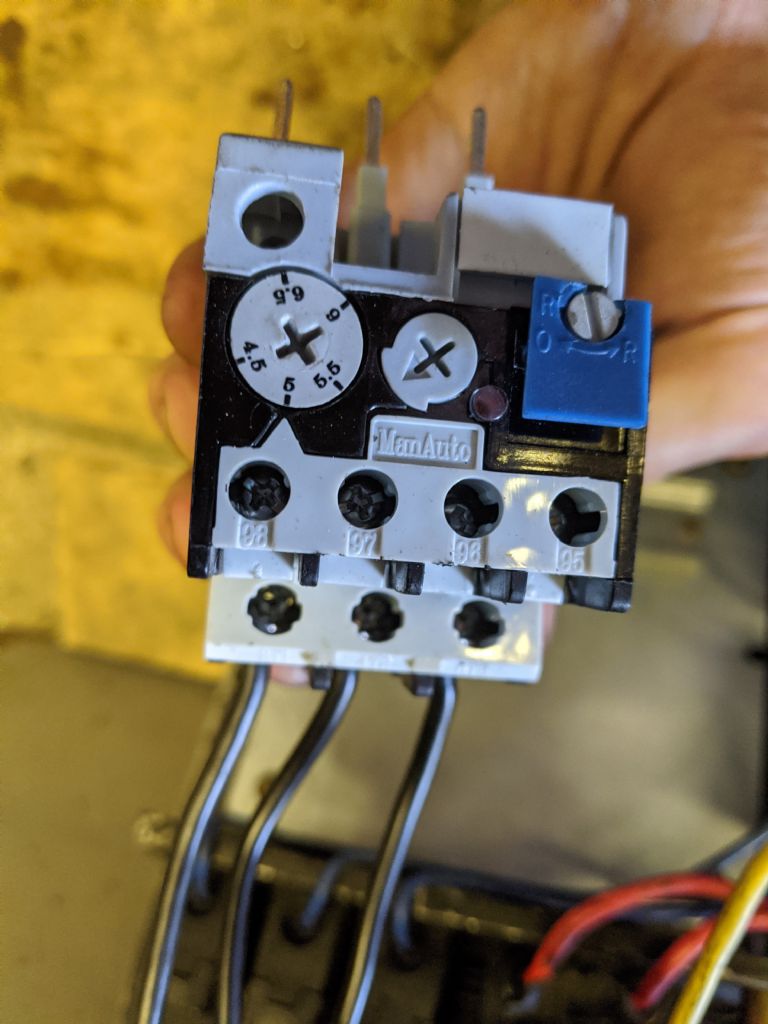

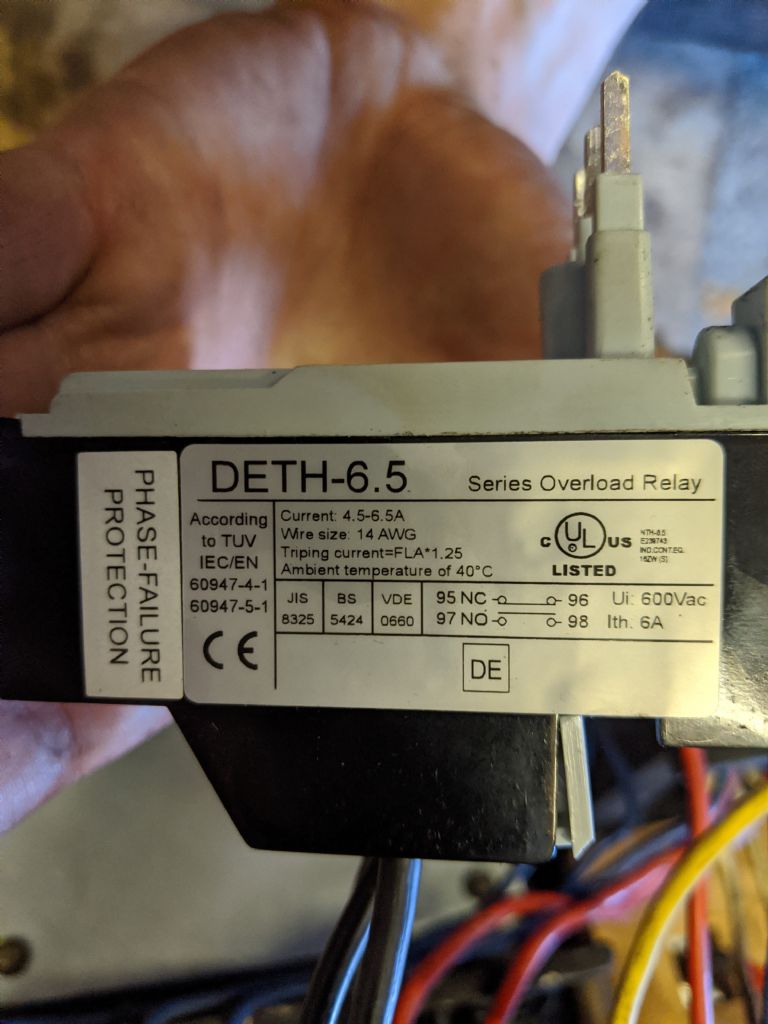

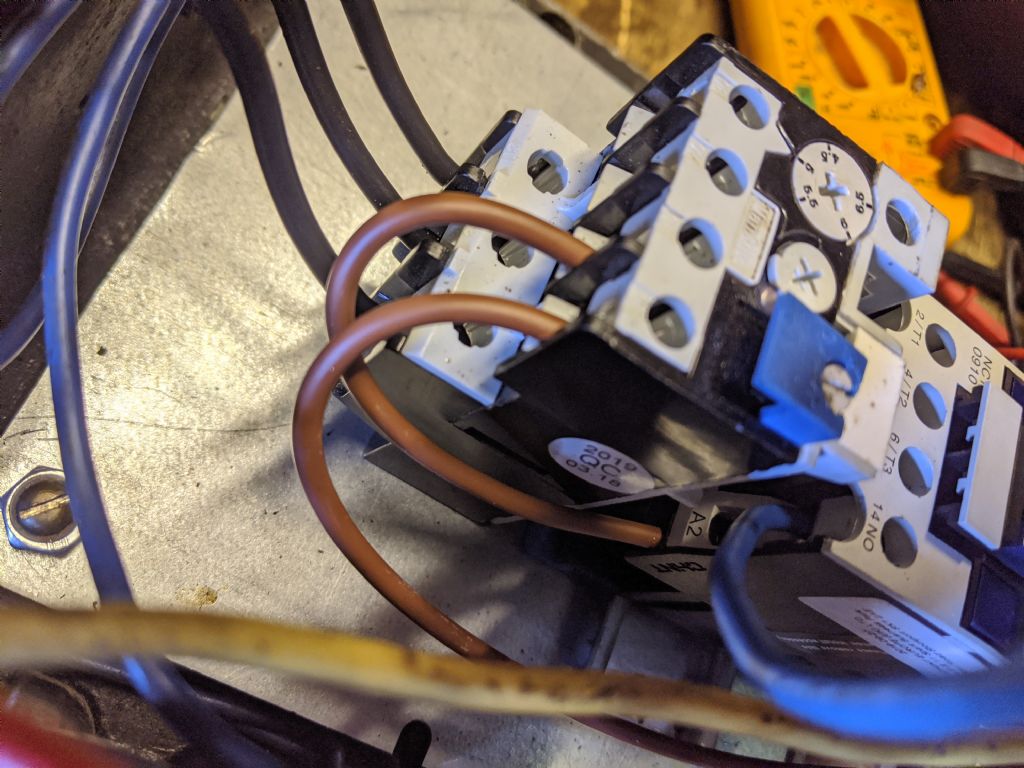

put a link from A2 (other coil connection) to one of the NC connections on the overload (Need a pic of the overload connections!)

Put a link from the other NC connection on the overload to one of the NO connections on the contactor holding in contacts along with the red wire from the C&D limit switch

Connect the blue wire from the C&D limit switch to the other NO connection on the contactor.

Connect the yellow wire from the C&D limit switch to L3 on the incoming side of the contactor.

With the end cover fitted, and the key switch on, check continuity between L3 and the yellow wire in the C&D limit switch, this confirms that the switches are working.

power up the lathe and lift the stop/ start handle, lathe should start and continue to run.

Press down stop start handle, lathe should stop.

start lathe again and turn off mains power, lathe stops.

turn on mains power, lathe should not restart until stop/start handle is moved to stop position, and then back to start.

This is a peliminary instruction set!! I need to confirm that the contactor connections marked 21/22 are actually NO, and close when the contactor is energised, and also need a pic of the connections on the overload to confirm the connection designations.

BTW! if you get it wrong it will simply not work As long as you have got the coil connections correct!

I need to go lie down for a bit!

If you compare the above instructions with the wiring diagram I did earlier in the thread, you will see they are in compliance.

Phil.

Edited By Phil Whitley on 26/03/2020 15:23:06

Phil Whitley.