So, progress has been made

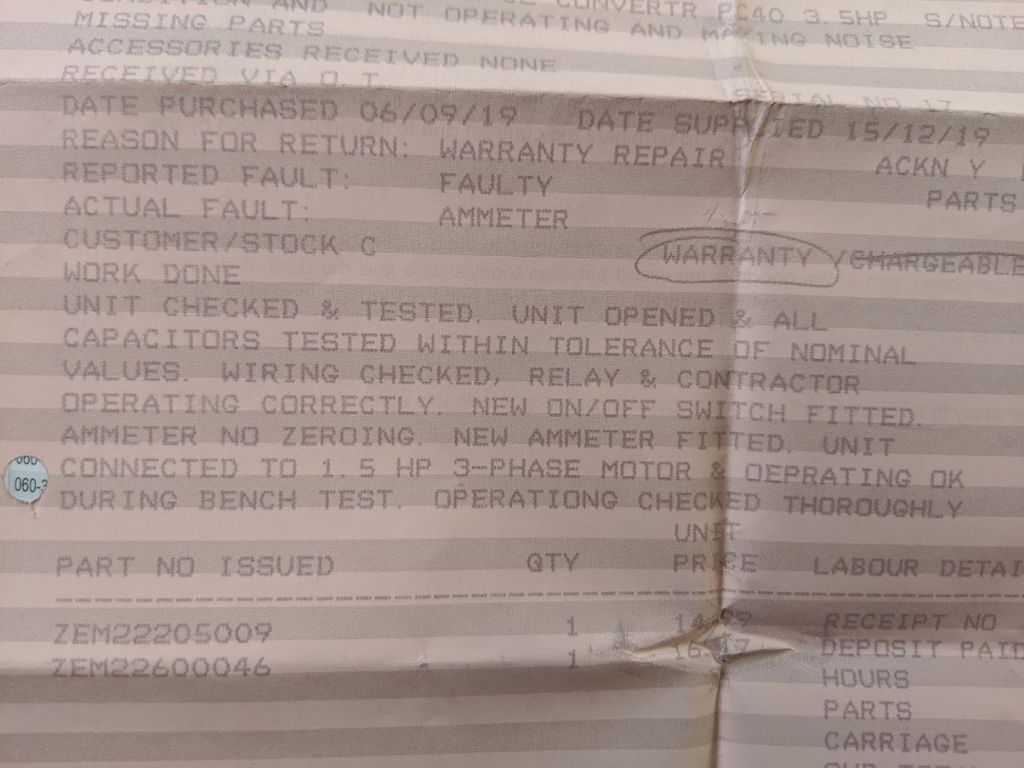

Pc60 just arrived so I've tried it out.

On the 1.5hp switch, after warming the lathe up a bit, it now runs in 400rpm and 600rpm, So definite progress

However, it will still not run in 1000rpm. It just sort of idles at 100rpm and doesn't get enough speed. It takes a few seconds to ramp up to 600rpm, but it does get there consistently now

As far as I know, static converters only give you around 2/3 of the power of the motor.

So, my thought is that the motor is actually only giving around 1hp of juice, which might not be enough to ever get into top speed.

But, when I went to see Phils lathe and had a feel of that, his chuck ran a lot smoother and more easily than mine, and I mean significantly so. But also, Phil mentioned that his bearings are shot and need replacing, but i don't know that that would make it run more easily.

So, my thoughts are that the motor isn't outting enough force in, or that the drive needs too much force for the motor due to some unfound friction issue (whether it be bearings or anything else)

What are peoples opinions on this?

I have found that the belts make a lot of noise and creak quite a bit, unsure how old they are. They seem too small for the lathe as when the motor is fully hinged up they are still tight. Also, one belt is more worn than the other, so travels more when you squeeze one, could this be an issue and should I replace them?

I have spoken to my electronics friend and i am trying to replace the contactor, overloads and lighting transformer, but we just need to find the correct components.

Thanks everyone

Phil Whitley.