Today has been fun!

Brazing is definitely an interesting topic. But let's start with the fun bits

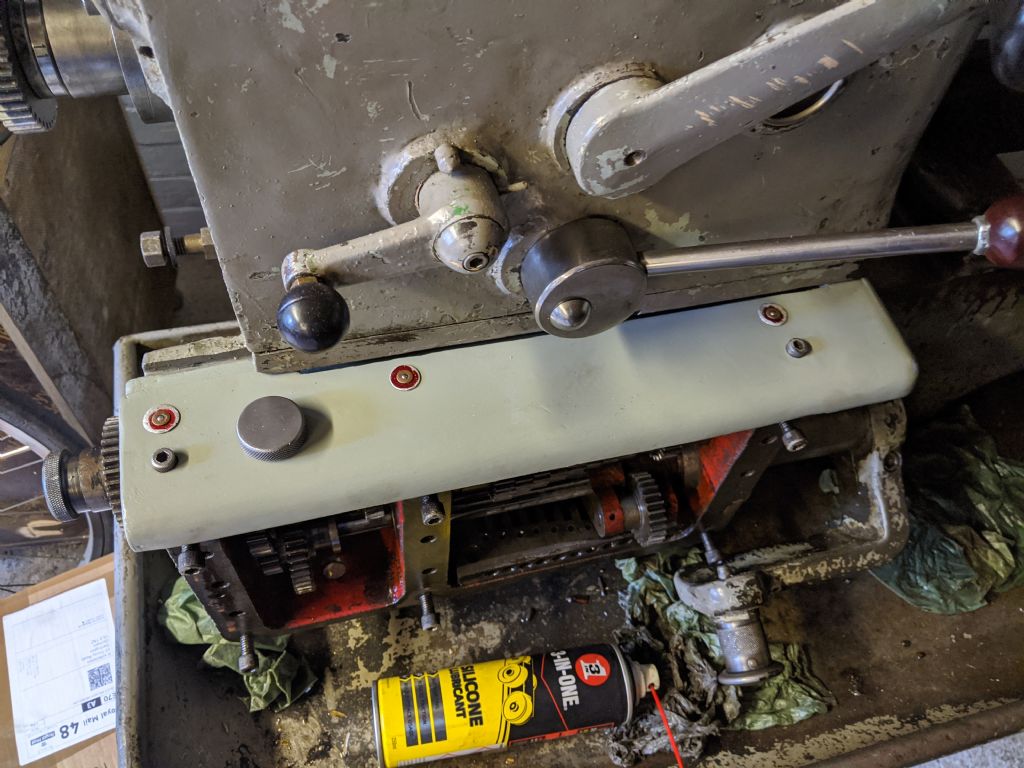

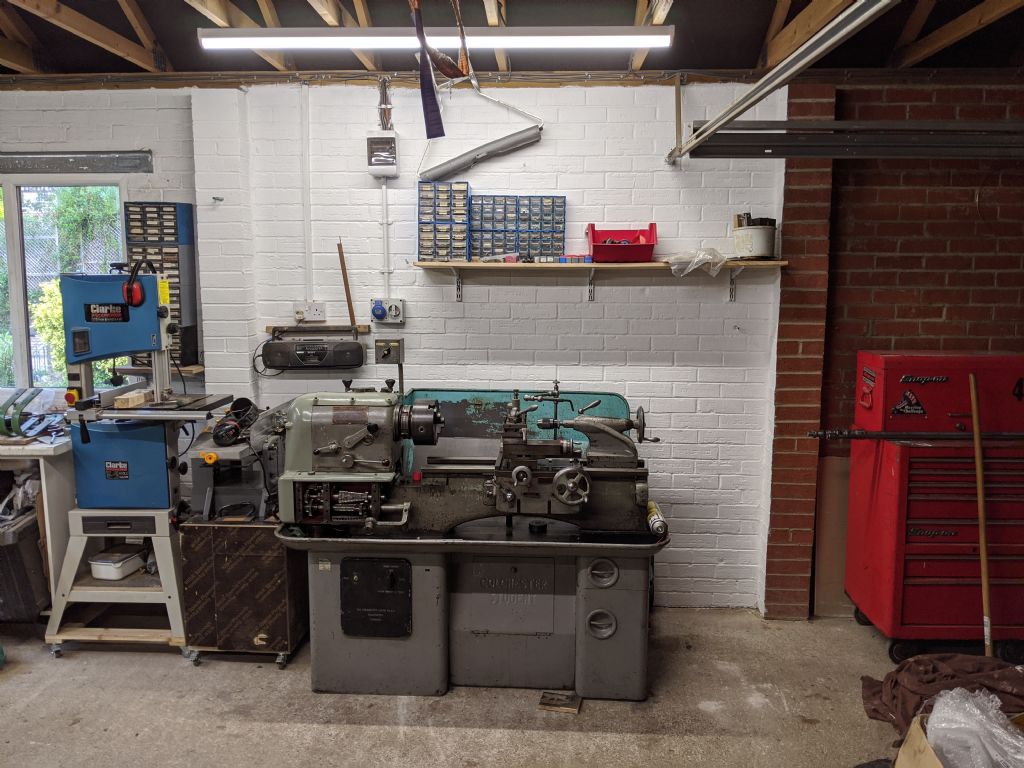

My friend has a very large lathe, its a bit of a workhorse. Although I've never seen him use it! It made my skin crawl, a fantastic machine that just needs a good clean

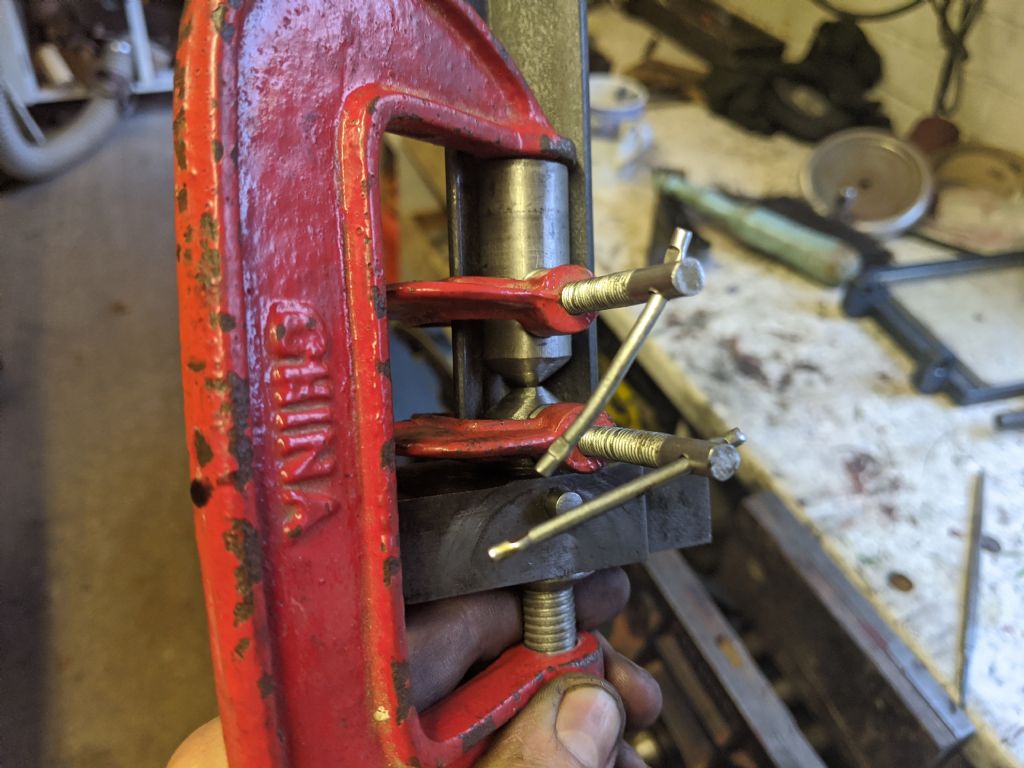

Anyway, so I had 2 things to braze at my friends, the rear bearing housing and the half nut

Last night I took the housing and ground down the broken area so it was smooth

So this should all be clean and good to braze

I did a sample on some mild steel, but I found that the mild steel glows differently to the cast iron, so I should have tested on some of that instead. Oh well, I've learned a lot today

I found tacking the shaft to be very difficult, so difficult that I just decided to not bother and just braze it all together, then if it all worked, I would have to clean it up on the lathe anyway.

I found that there was not enough meat on the lower bit of the shaft to clamp it properly into the angle iron, so they had not joined at the right angle. I am not going to bother wasting any more time with this part. I'm just going to wait for the spare one to get here

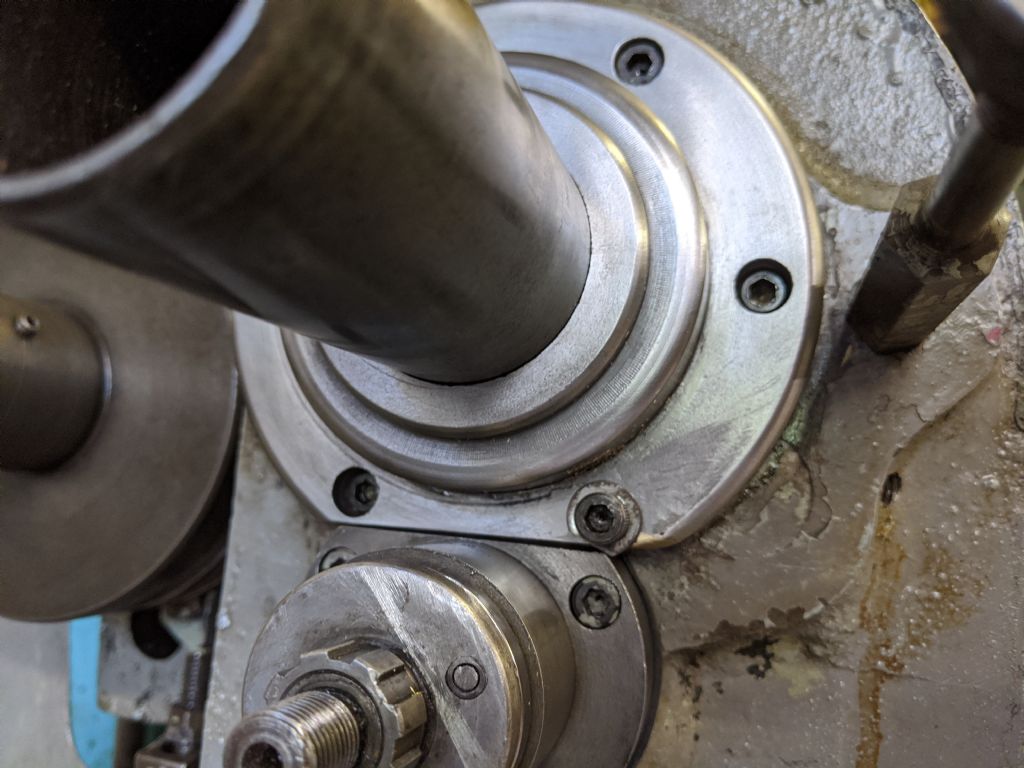

So, onto the housing. The housing was very tricky since the hole had a very thin wall, which I ended up melting

So this then became just a very large area to fill with braze.

I did change tips and get to a better flame so it was sufficient for heating

All filled up, but a mess. I went to use the other mans lathe to clean up all of the excess bronze, but not to really touch the metal.

I don't have any pictures of the actual turned surfaces, but there will be one in the next post. Its been a long day and I'll do it tomorrow

It was quite a nice lathe. A harrison model. Still, it needed a good clean as well, but at least it worked.

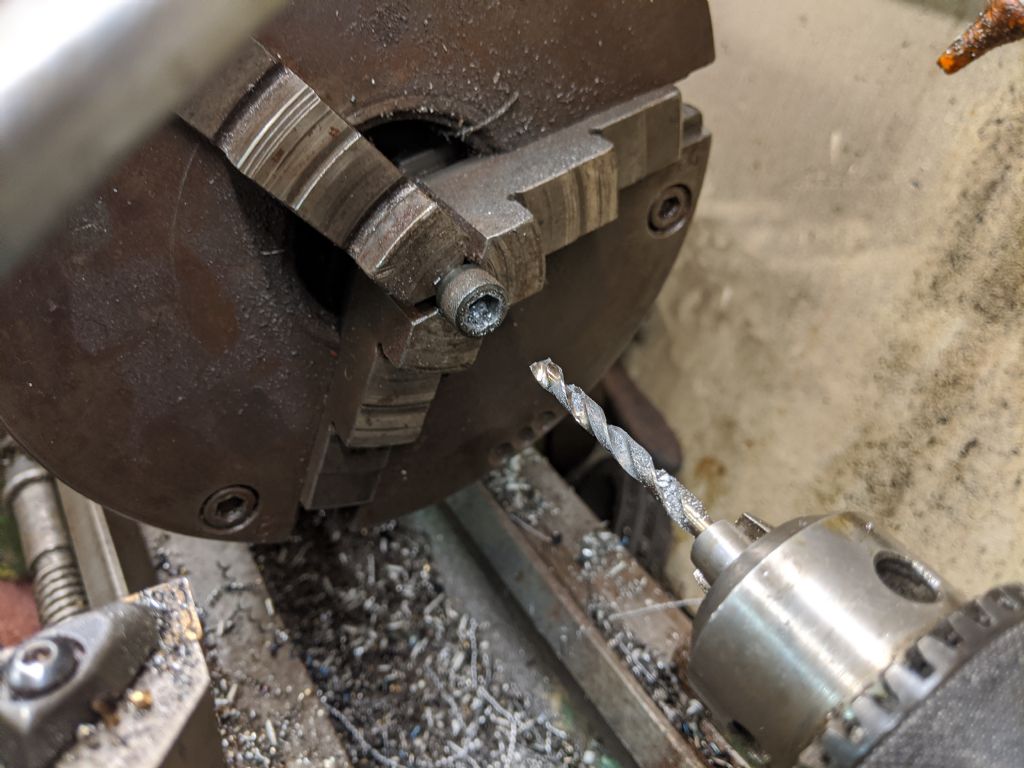

I also used the lathe to drill the center of 2 bolts out to 5mm

Then I tried to tap them m6, but the tap got stuck. It is still in there, but I didn't want to risk trying to get it out at my friends. I'll do a better job at home. I'll get them tapped somehow.

Anyway, the housing is machined down closely enough so i will be able to finish it off with files and sandpaper or whatever. Good progress. Then I'll just put the rest of the lathe back together

My only issue will be getting the hole that i have filled redrilled in the correct location, but I have a plan!

Phil Whitley.