Fantastic progress today, I'm very satisfied with what I've done

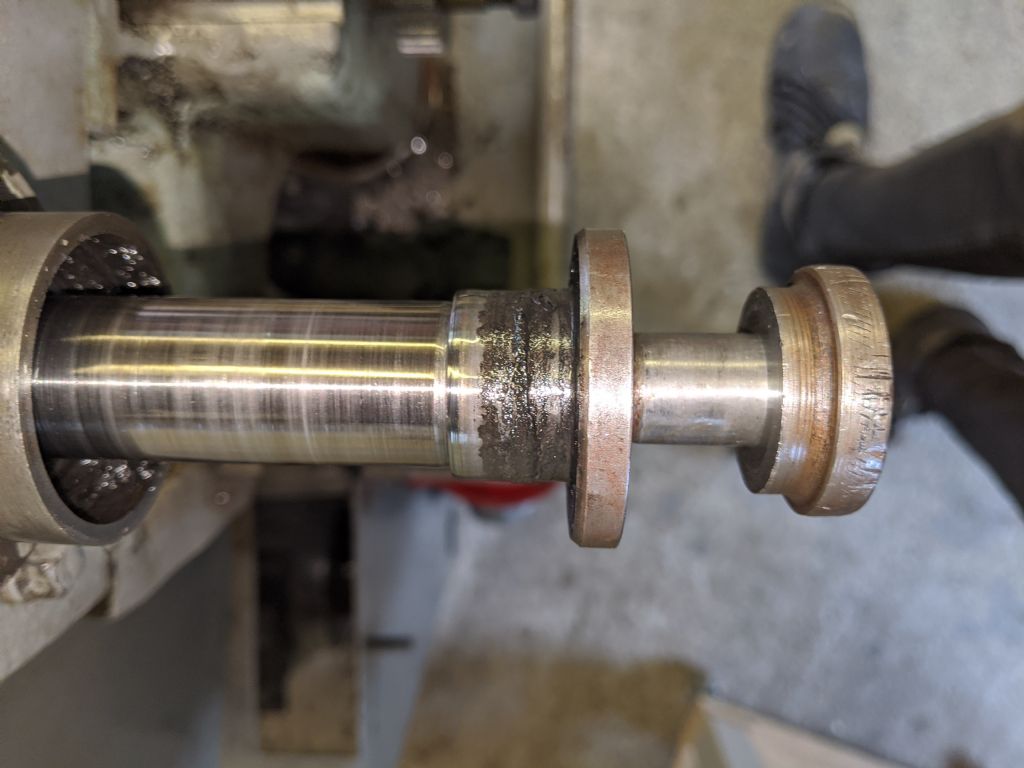

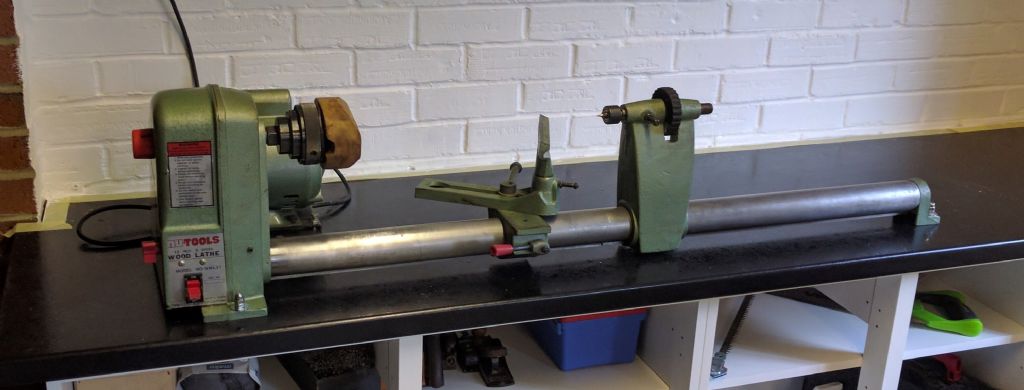

I began by moving the lathe away from the wall and starting to remove the main spindle. It must be the 4th or 5th time I've taken it out now, so it was very easy.

Side note, Phil and Herman. If you decide to use the nitrile rubber gasket material you should know that it creates a very tight seal, almost sticks the two faces together, so it was a little bit of a struggle to get the parts off. But well worth the effort for it to not leak

Anyway, as I was taking it to pieces I saw the usual leaking spots. It drips out from below here, however, this could also be leaking from the main spindle where the casting is broken. Either way, I need to replace the gasket

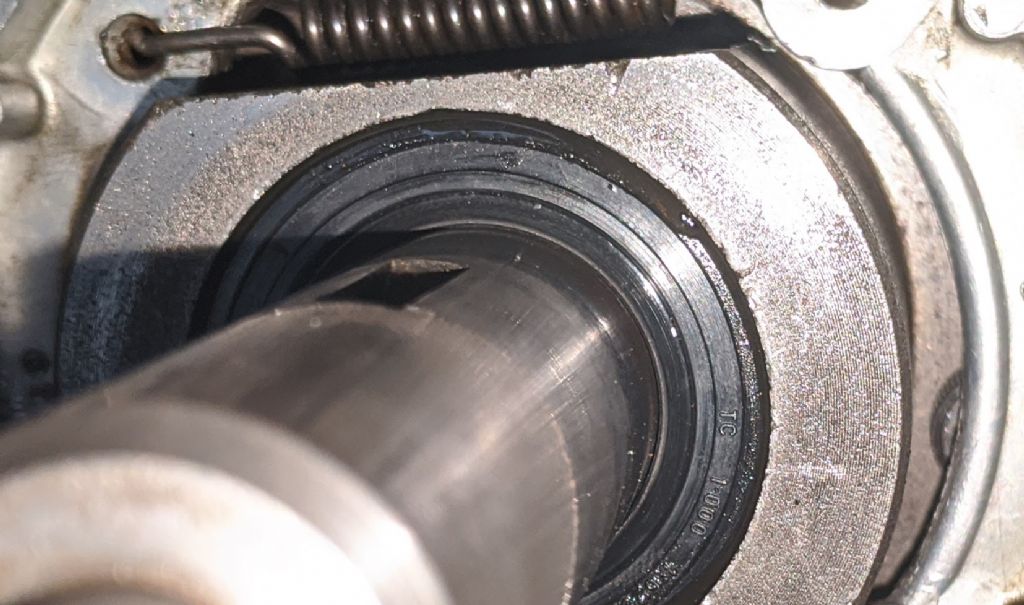

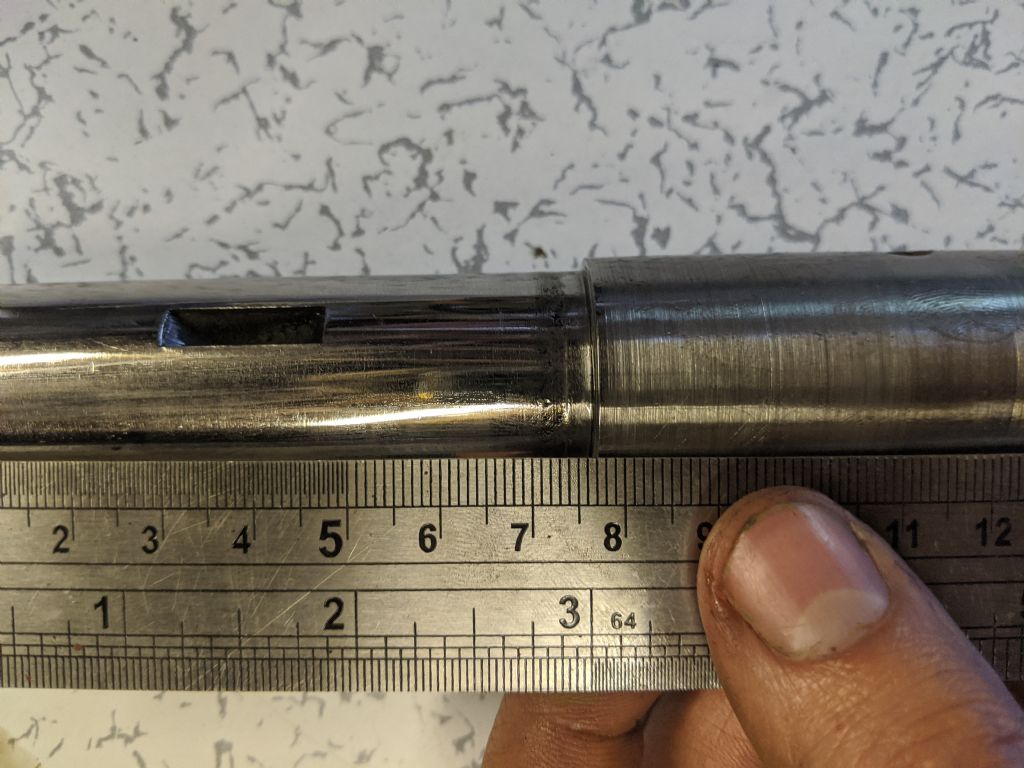

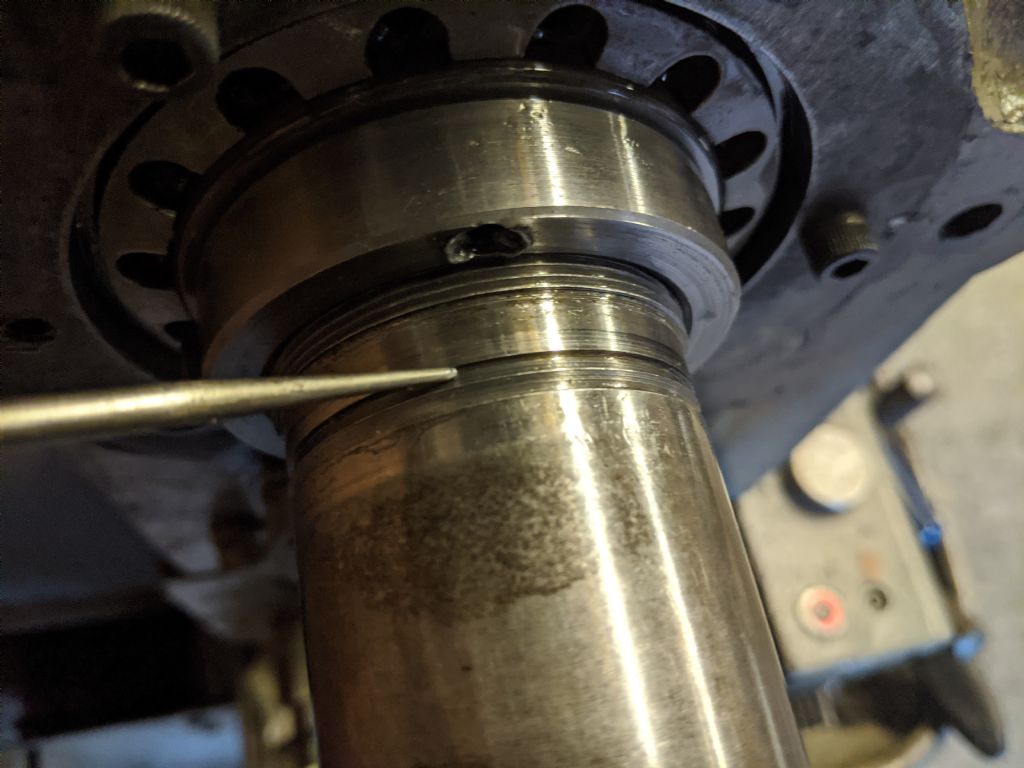

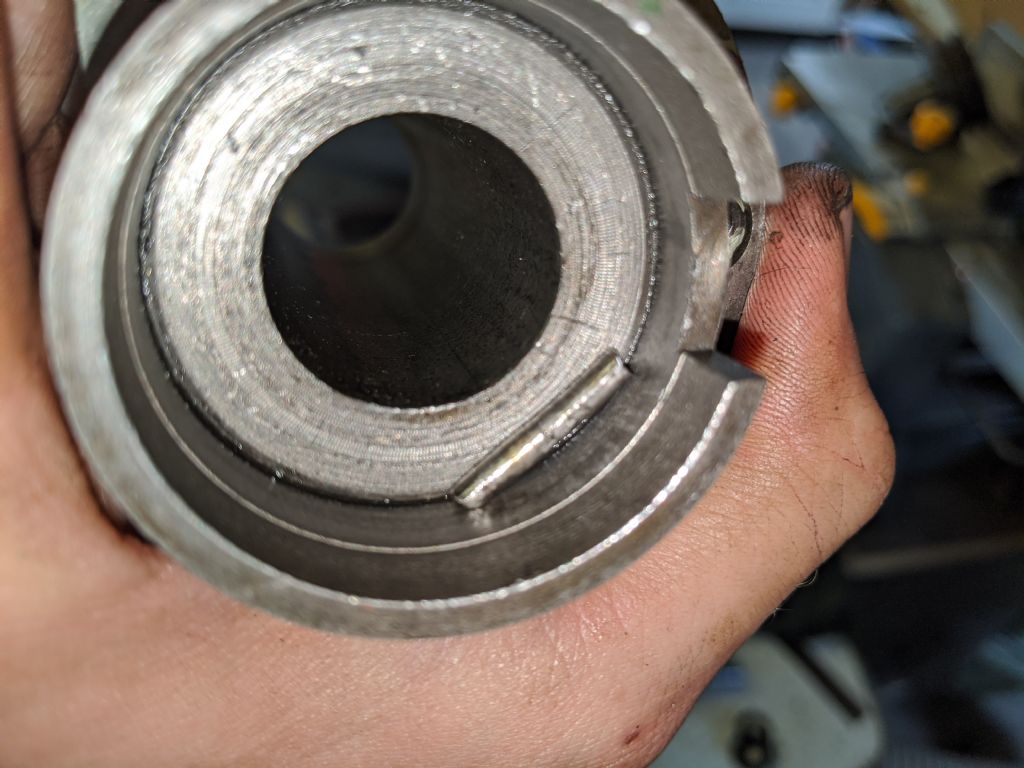

Looking at the back bearing cover housing there is definitely space for a ring of some sort to be placed, and there are grooves in the main spindle too. I am sure there must be some sort of seal here too since a little oil leaks out. But I can't find anything in the manual about it. Thoughts???

Then I proceeded to remove everything else. I blocked the bottom hole of the sight glass with a rag, then I used a pipette to repeatedly fill it with glass cleaner. I managed to find some pipe cleaners in my grandpa's old toolbox so that was a great help. It was tricky, but maneuvering them inside helped to clean it out. I let it sit, then cleaned, then filed it back up and let it sit many times. And I am very pleased with the result. Looking closely it seems like there is a crack on the inside of the glass, or maybe a scratch, but it doesn't go all the way through and I'm not quite sure how it got there, so I'll leave it.

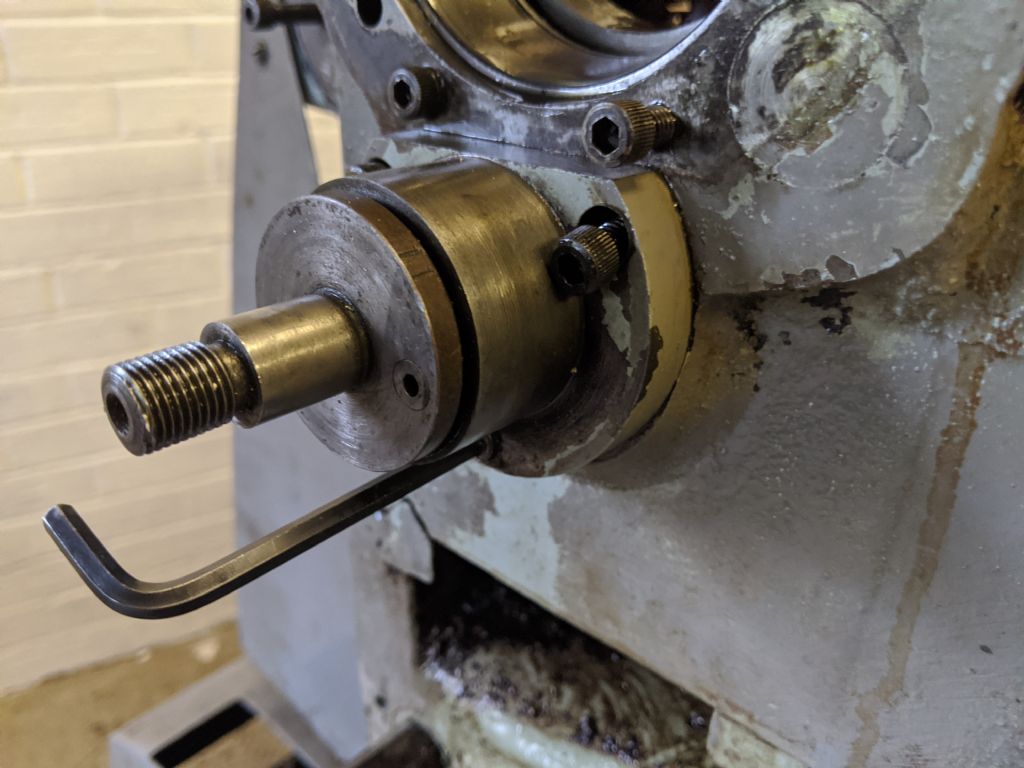

Then I moved onto the removal of the forward-reverse spindle. This stopped pretty quickly since its held in by a circlip which I need 90-degree circlip pliers for, but I only have straight ones. So I'm stuck for now, however, I have ordered some. Click and collect from Screwfix so they'll be ready soon I hope.

Looking at the manual of the lathe, there is a bearing and an oil seal on this shaft, so I will replace both.

This means ordering more parts and waiting a while, so I will take the threading gear box to pieces again and clean the sight glass in there the same way. I'll also take the tumbler arm off again and put that back on properly since after I played with it it has started leaking a little.

While I was waiting between the sight glass marinading I painted the wall behind the lathe white. I'll do a second coat tomorrow, but It's looking a lot brighter. It should make lathe work a bit easier.

The threaded hole in the headstock used for mounting the splash guard in my lathe has been used for a chuck guard. I don't tend to use the chuck guard as it just gets in the way, So I'll take it off. I will also try to get the splash guard from Tracys lathe and fit it to mine if possible, but postage may be an issue, and that's if she ever gets back to me!

Plenty to do

Phil Whitley.