I'm sure my background of a nice brick wall works perfectly too

I've had a very productive day. I finished some jewelry boxes, similar to the one I made for Phil, but with trays and sections. Then some castors arrived in the post so my bandsaw is now free to glide around the garage. Then onto lathe work…

I picked up some m8 bolts from Toolstation so I could work on getting the panel fixed in place properly

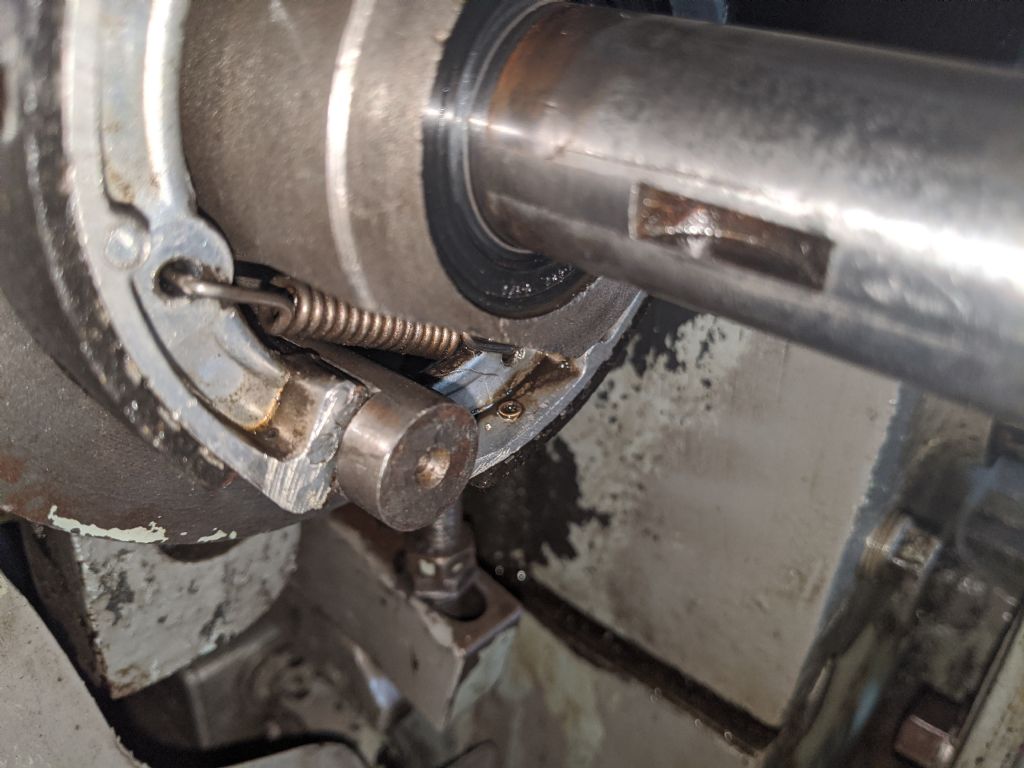

Before I could turn the bolts down I had to put the starting lever back onto the lathe, so I took a picture of the back. Tracy finally got back to me today, so I will try to see if she can send me the starting level of her lathe so I have a spare if I mess this one up!

Chalk test, with a gold highlighter as I didn't have any chalk. The belts are not even. Can this be caused by a misaligned motor too?

Anyway, I'm running on 1 belt now and the lathe is much more peaceful. The link belts seemed a bit expensive when I can just use one belt, especially since I just bought these belts, although I do see the attraction.

The bolts were screwed into a piece of aluminium I tapped, then faced, and turned to the dimensions I wanted.

Then I cut the slots just with a hacksaw

Then I prepared to drill and tap the lathe body.

This went surprisingly well

Then I polished the bolts, gave them a brushed finish, then cold blued and oiled them.

Fully installed, I'd say they look rather fitting.

They pull the panel in tight

Then I tried the light and gave the panel a bit of a bang around to see if the light went off.

The light went off again

I've still fixed the stripped threads and improved the panel's fit, which I'd say is productive enough, but It annoyed me that it didn't fix it, so I started testing things

I cleaned the contacts of where the 2 legs for the lighting power leave the brass plug bit, that didn't help

I cleaned the surface of the slide lock fuses, that didn't help

Then I bypassed the switch to see if that made a difference, low and behold it stopped flickering when I banged it, I think. I could be completely wrong once again, I'll replace the switch and see.

I've ordered a toggle switch to replace it with since I found a picture and there should have been a toggle switch there anyway. I ordered it a couple of days ago actually, so this is currently working in my favour until it turns out to not be the issue.

Phil Whitley.