Can anyone offer any hints or tips on how best to use this stuff?

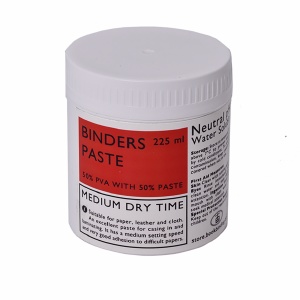

"Bookbinders Paste – Binders Paste – Medium Dry Time" (from Shepherds)

**LINK**

What I like about this paste is:

A) It doesn't seem to cause the book cloth to stretch and/or curl… (unlike the "Noble Craft – Professional Crafters Glue – PVA Glue Strong Craft Glue" which is a nightmare in that regard!) My guess is that it has very much less water in it than the PVA glue.

B) Unlike the "Collall – All Purpose Glue" it seems to give you seem to have plenty of time to get it to where you want it before it start to set.

Background

I am using it in two different situations:

A) Bonding millboard to millboard

B) Bonding book cloth to millboard

NOTE: For bonding the book cloth to millboard, the book cloth will be acting as a hinge.

Questions:

1. Just how thickly should it be applied?

I can achieve a very thin, even layer if I use a plastic spatula.

2. To speed up the setting process (which does seem VERY slow) should it be allowed to dry for a minute or so before the two sides are brought together?

3. How can you best avoid the glue going beyond the edge of the part?

4. How long is it supposed to take before it will form a half-decent bond? – "over night"?

5. Is it important to apply pressure whilst it sets?

6. How flexible is it when it is fully set? I mean once it gets fully just how flexible/brittle will it be?

Do you have any other hints or tips about Binder's Paste

With thanks

J

PS I find the Collall 'All Purpose Glue' useful because, being solvent not water based, it doesn't warp anything (unlike PVA)

Sometimes it is also nice to be able to move fast between successive stages of a project, due to its rapid setting time. But it I would like to find a way to slow it down. It is also rather too thick. Maybe I could thin it using a solvent like acetone or Isopropanol?

PPS What about EVA

e.g. "Eva-con R Adhesive" from Shepherds

**LINK**

When Shepherd talk about a "Fast Dry Time" how fast is that likely to be?

Will it be like Collall where seconds count – or closer to the Binders Paste… where it seems to take an hour (??) to start t set and 8 hours to go properly hard (??)

Shepherds do talk about mixing it with starch paste to slow it down – but I don't really know how I would do that….

I am feeling out of my depth…

Any advise gratefully received!

John Smith 47.

is presumably virgin where was greyboard has been recycled, yes?

is presumably virgin where was greyboard has been recycled, yes?