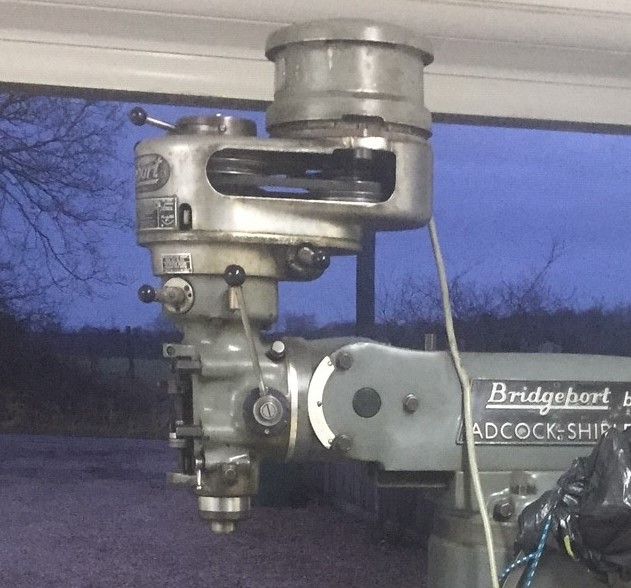

As Chris says there is some evidence that Bridgeport motors and Transwave converters don't play well together unless everything is just so. Presumably some interaction between the motor design parameters and Transwave design parameters pushes everything to the edge.

Basic rule is make sure that all the control gear runs off the incoming mains driven phase. Both the others are generated and will have no power from a static converter until the motor is running. Transwave a s breed are sensitive to cable losses. You need a good incomer supply from the utility to the house and a hefty cable to the workshop. At least double book size is desirable in my experience.

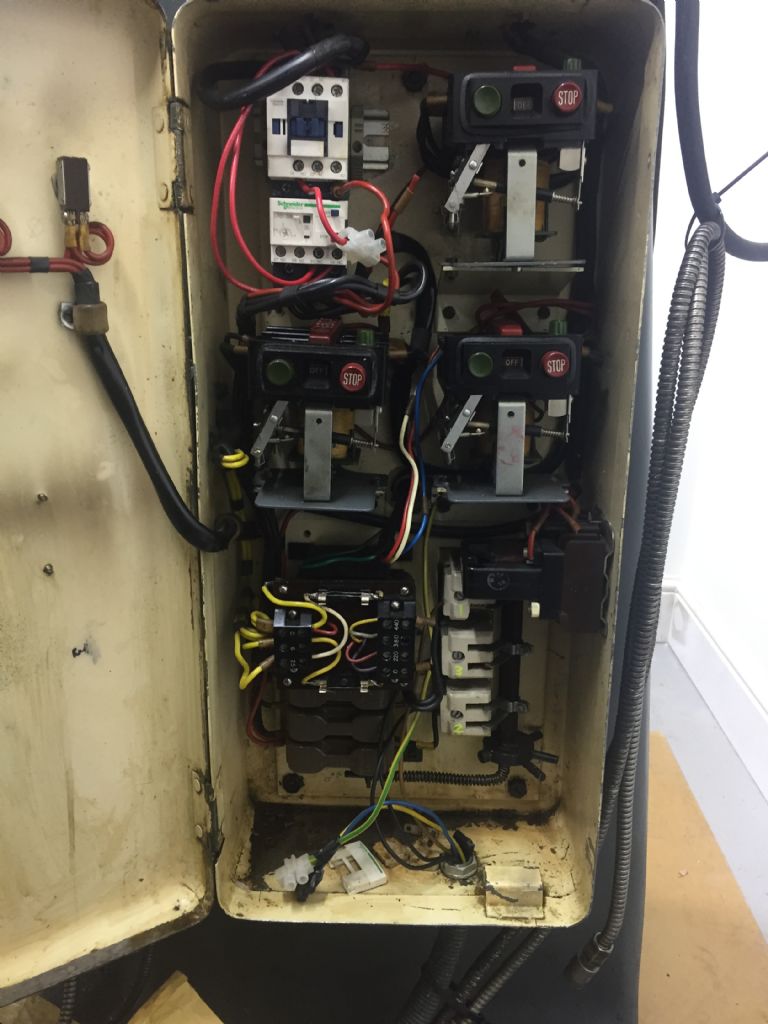

If you have the switched auto-manual reset overload devices on those old contactors its worth checking for proper operation and giving a good dose of switch cleaner. They are known to get a bit iffy after many years. Probably 'cos they pretty much never operate and get bored after sitting in one place fot 50 or more years.

Old Bridgeport motors have a certain reputation for not lasting well when hooked up to a VFD. Hard to be sure how much is inherent and how much is just plain age. I know of Bridgeport motors that have failed after some time on a VFD (5 to 10 years). I'd prefer to use a decent branded VFD and, probably, fit inline filters to reduce switching stress. Bridgeport motors being seriously non standard its worth spending a bit more to be safe.

Despite what you may read on the Internet from "Build your own converter" mavens converters are not inherently simple "follow the diagrams and plug the Lego together" devices. Over the past decade and more the renewable energy folk have put considerable effort into engineerign analysis of the Steinmetz motor connection set-up on which all converters are based. All the papers I've seen involve very serious maths. None claim to be comprehensive or even the last word in however a limited fashion.

I've long put converters in the "If it works it works. If it doesn't it doesn't." category. Well D'oh! By that I mean something that, if you don't make a silly mistake, will work after a fashion and can usually be refined into going better but if it refuses to co-operate after the initial basic checks prove out its not worth expending great effort trying to make it go. Even if you do get it going after a fashion its never going to be properly satisfactory.

How do I know! After the fourth game you begin to get the idea.

My Varispeed Bridgeport ran adequately off very old MotoRun 4 hp (?) static converter, albeit with the switches set differently to what the book called for on a motor of that power. Worked a lot better when I added a 5 Hp pilot motor to make it a pseudo rotary converter.

My pal Mikes Bridgeport was very hard work to get running reliably on a Transwave 5 hp rotary converter. Like Chris we had major issues with it not running reliably for long periods and occasional refusal to start. Eventually after much swapping of phases and re-arrangement of wiring we found a set-up it was happy with. I had meters, experience and a comprehensive vocabulary of swear words to help. These days it would get an hour of playtime then a VFD but that was not a financially viable option back then. Subsequently we had similar issues with a Hydrovane compressor, which did get a VFD after an hours worth of playing! Mike subsequently spoke to Transwave and they advised seriously uprating the cable between his workshop and the mains incomer. Poking around afterwards showed everything else in the workshop to be working much better on the big cable.

Clive

Edited By Clive Foster on 14/01/2020 10:10:11

Aaron Brailsford.