Not seen a Warco Super Mini myself so it is possible it comes fitted with an unusually weak belt. I think it unlikely to be the root cause because parting off is notoriously difficult especially for beginners, and triply so when they are cutting a difficult material on a small lathe.

Parting off is one of those operations where everything has to be 'just right' and this is hard to arrange. Particularly on a small lathe, it's likely that the tool won't be held straight if too much pressure is applied. Front tool posts bend (they do!), the work bends, saddles twist and lift on the gibs, and the saddle can be pushed along the bed. If any of these happen, expect a dig-in. Unfortunately it's also vital that enough pressure is applied to cut. If the tool is allowed to rub, it goes blunt, and the friction generates enough heat to soften the metal causing the tool to grab and another dig-in. This makes parting off a balancing act and – particularly on a small lathe – the onus is on the operator not to make any mistakes. Setting up requires all sources of movement to be minimised – lock the saddle, reduce overhangs, tighten the gibs, avoid worn lathes etc. Even after all these things are done, a rear tool post out-performs a front tool post because they are more rigid.

Then the operator has to know his lathe and the materials he's using so he can optimise cutting speeds, pressures, lubrication and swarf clearance. There are significant differences between alloys, I find brass always parts well provided the tool is sharp. Aluminium alloys are often bothersome because they can be sticky. I doubt there's anyone on the forum who's not had bad parting experiences.

One thing about the learning process that might help. Quite often people picking up new skills plateau – they get so far and suddenly can't improve no matter how hard they try. The cure is do something else for a while, and then have another go.

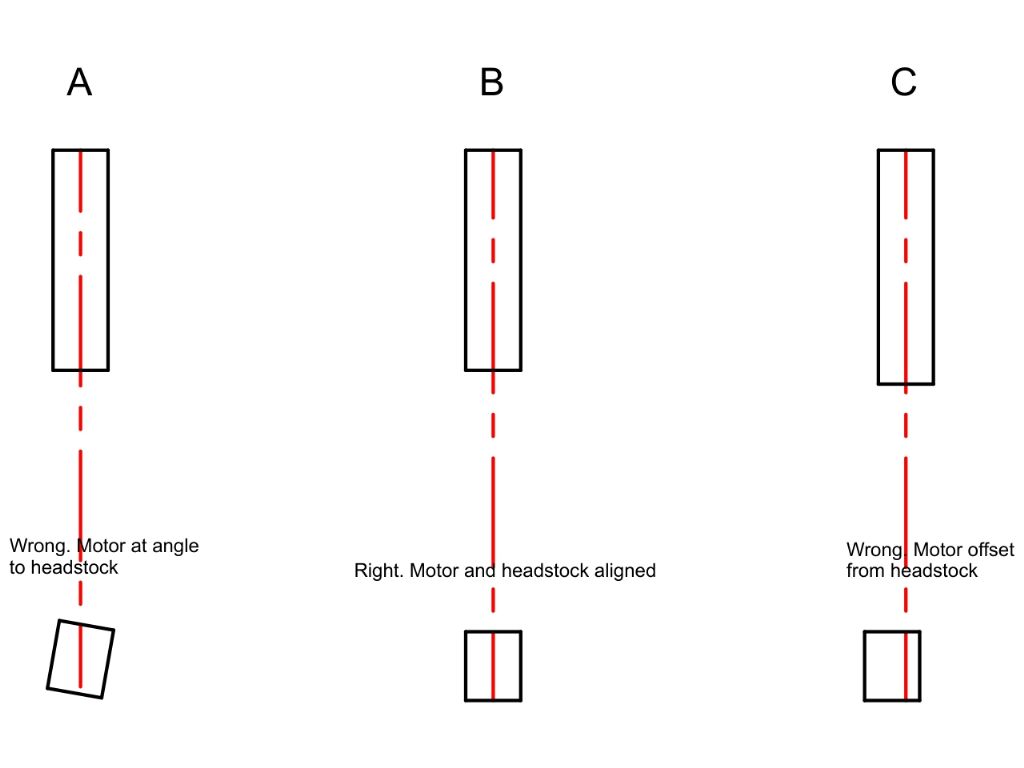

Although the belts are breaking during parting off, I think something else is damaging them. When you fit the new belt, it's worth double checking alignment as well as tension. Depends on how your lathe manages the adjustment, but changing tension might interact with alignment and vice versa. Getting everything trued up could be another balancing act.

The diagram exaggerates getting it wrong, but quite small misalignments between the motor and the headstock pulley can soon damage a belt. I suspect that, compared with ordinary types, a toothed belt could be extra vulnerable. If the teeth become stress raisers and there's a sideways tearing action I can imagine the belt quickly failing.

When the new belt is on can you post some photos?

Good luck,

Dave

Edited By SillyOldDuffer on 19/11/2018 12:15:42

andrew lyner.