Bit of history about the lathe that i know of since i've owned it.

I got the lathe in around 2000/2001 when i still had my workshop in the UK. It came via a good friend who was emigrating, and came in a part ex deal with a couple of motorcycle basket cases. Complete bikes, part restored, in parts, an iron head Sportster and a T140 Triumph Bonneville. He was a commercial aircraft mechanic working from Norwich airport, and was going to use the lathe at home (his shed and projects had the best of everything, tools, aftermarket parts etc befitting of a certified aircraft technician) prior to him deciding to up sticks from the Norfolk coast and move to southern Spain.

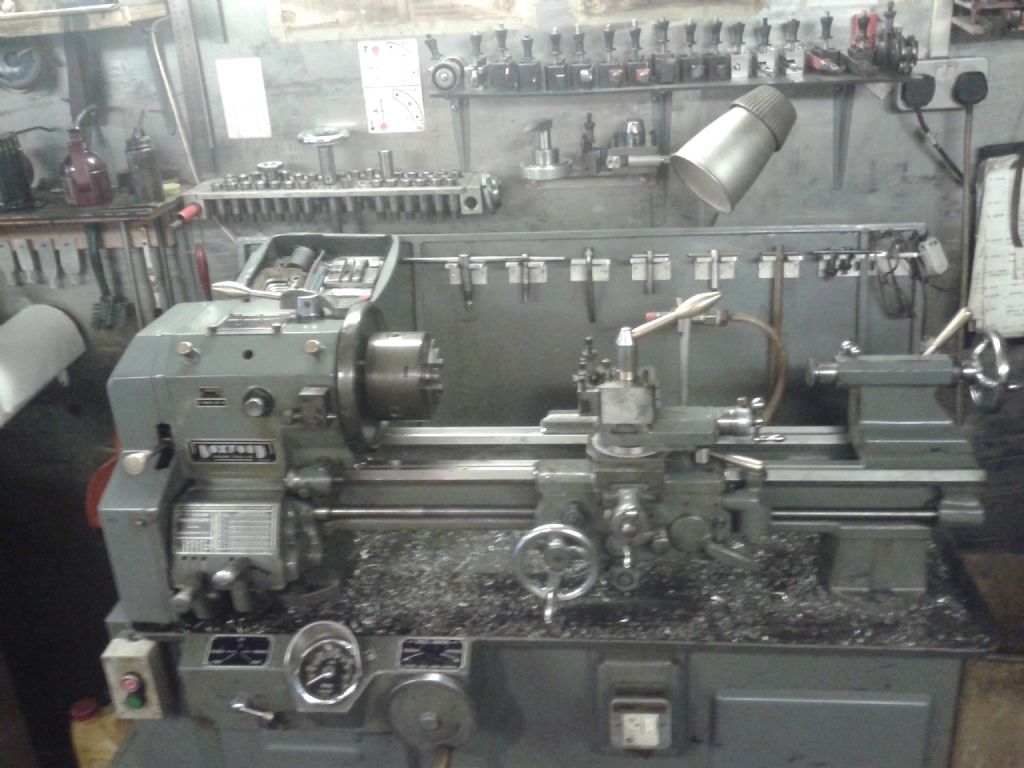

I was'nt that interested in the Boxford, it was part of the deal with the bikes, as i had two Colchesters (a 24" Student, and a 36" Master, both round heads) in the shop, i just put it in the corner, covered it up, and thought one day, maybe tart it up and out it to some shed dweller, or home machine shop enthusiast, or heaven forbid, a model engineer. It was in lovely condition and pretty much fully tooled.

Anyway, 2003 rolls around, i've had enough, decided to shut the shop, sell up, sell the freehold, move abroad, though to NE Thailand. In hindsight, i should of kept one of the Colchesters (love my round head Colchesters), but weight, and lack of cheap converters, inverters, at the time, made me decide to sell the industrial stuff and keep the little Boxford.

The Boxford was 3 phase, again at that time inverters were pretty new and pricey, and converters were outragous money, and did'nt have a great reputation. Being in the trade, i got a machine tool service engineer friend of mine to find and locate the very rare correct 930 rpm, 1.5 hp single phase motor, s/hand, and we fitted it in with a bunch of swearing and skinned knuckles. New belts at the same time. One of my employees knocked up an extended left hand side motor access door (the replacement 1 phase motor was 50% bigger than the original 1 hp 3 phase motor), and also fabbed up a lovely splash guard. All got colour matched at our local powder coaters. Then i got a professional machine tool electrician in who owed me a favour or two (again, handy knowing people in the trade), who completely re wired the whole lathe, to run off a household plug (light and suds, seperate plugs).

The lathe has an imperial gearbox and leadscrew, but both top slide and cross slide feed screws and dials are metric (?).

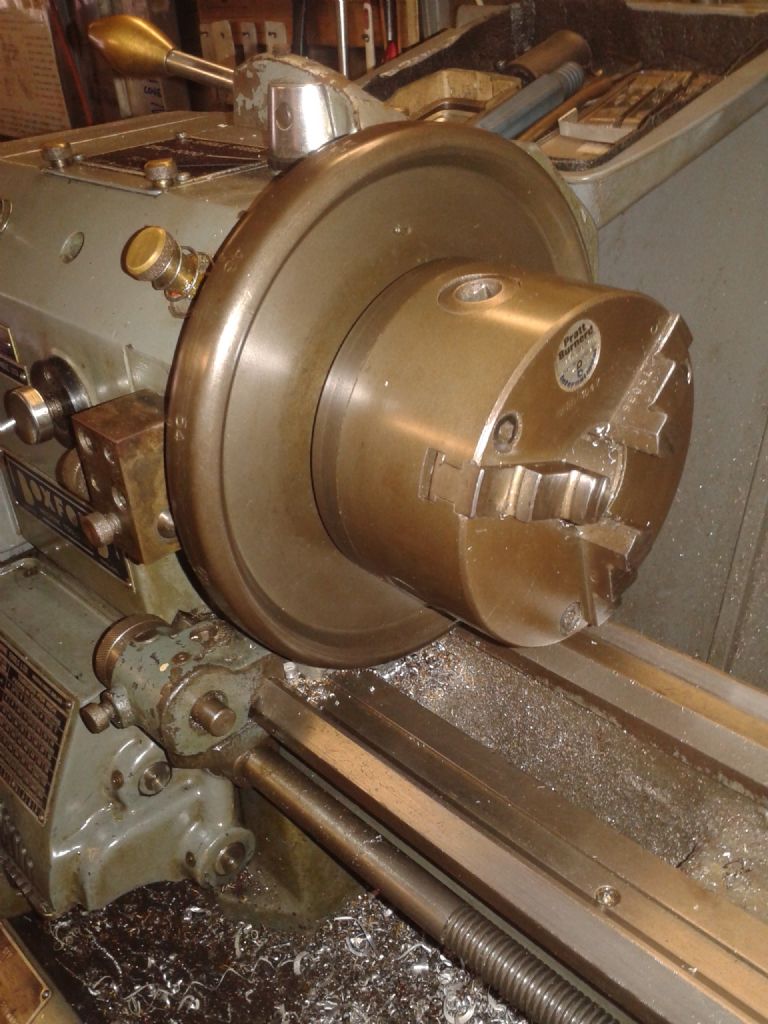

The lathe came to me with the correct 3 jaw chuck, 4 jaw, faceplate, catchplate, both steadies, Crawford 3C collets (90% complete metric and imperial c/w several duplicates) and all gubbins, all the change gears required to cut all threads, 4 TPI and below and all metric inc the big 100/127 compound gear, correct indexing 4 way toolpost, and all the usual stuff that fits in the headstock and tailstock spindles.

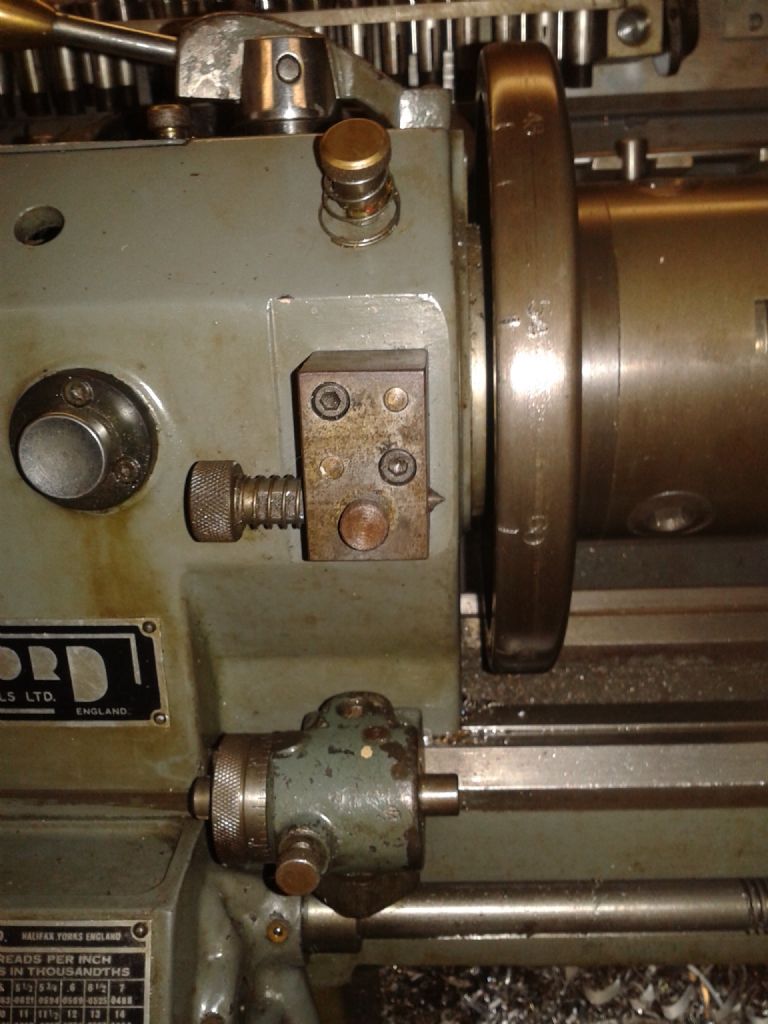

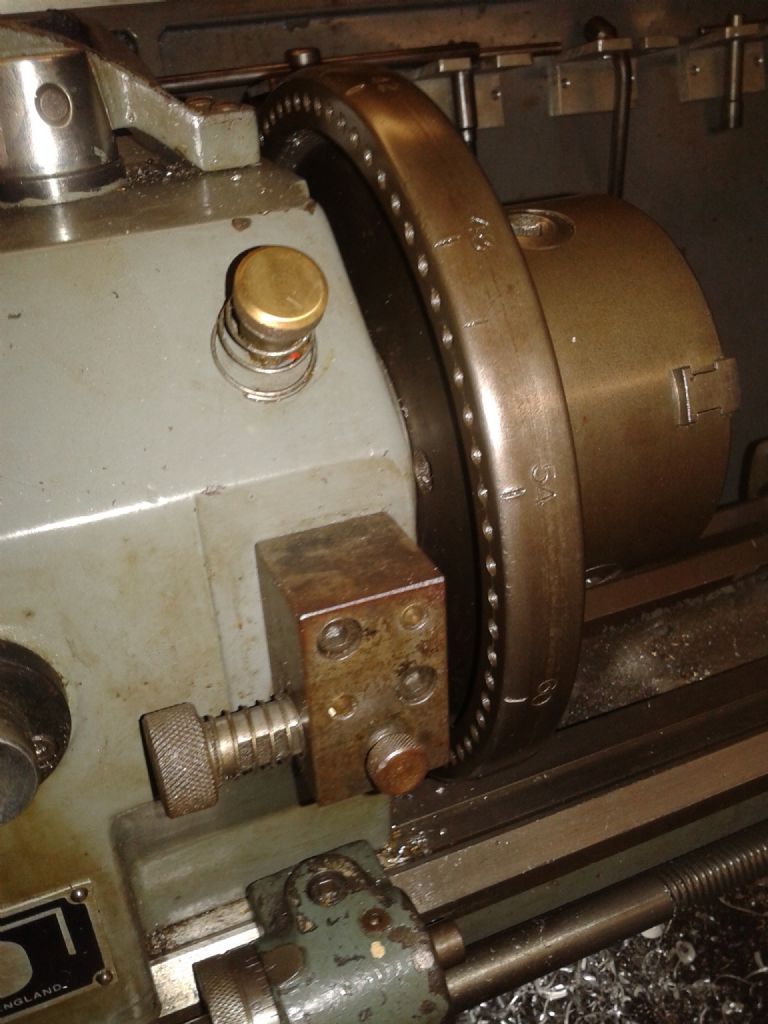

So, i moved out here in 03, and my containers with Boxford followed me out here in 05. Prior to storing the lathe, i purchased a Bison Dickson QCTP from Cromwells. The t slotted cross slide was purchased from the UK since i've been out here, still have the original. All the plastic balls on all the handles have been replaced with brass. ditto, all my machine tools, TS mill, Boxford shaper, Stent T&CG, Taiwan pillar drill, none of them have any plastic on, everything on the end of a handle is brass.

That dividing wheel/disc is useful for spinning the chuck by hand with gears dis engaged, but i have rarely used the dividing hole facility, having an H/V rotab (c/w plates) for the mill and shaper, even though it's handy for 3, 4 and 6 marking out on discs for radial bolts etc whilst still set up in the chuck. Oh, and the (poorly) stamped numbers on the rim, every 6, not original, my handiwork unfortunately.

This lathe has probably seen more work in the last 12 years than in it's previous life. It gets used a LOT, i love it dearly, but on those big jobs, too big for the spindle hole, or some nasty 5" diameter steel, i do miss my round head Colchester…

thaiguzzi.