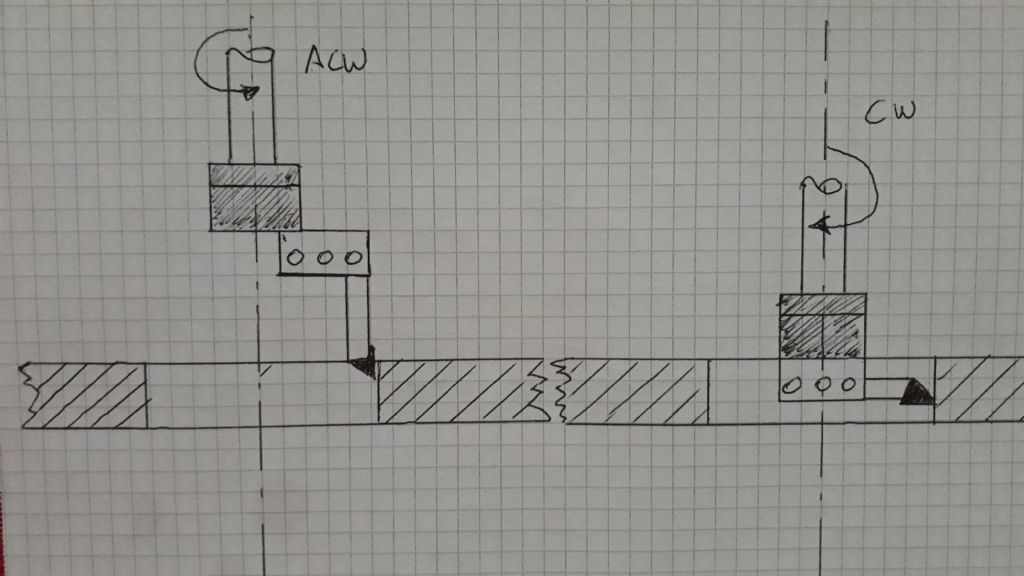

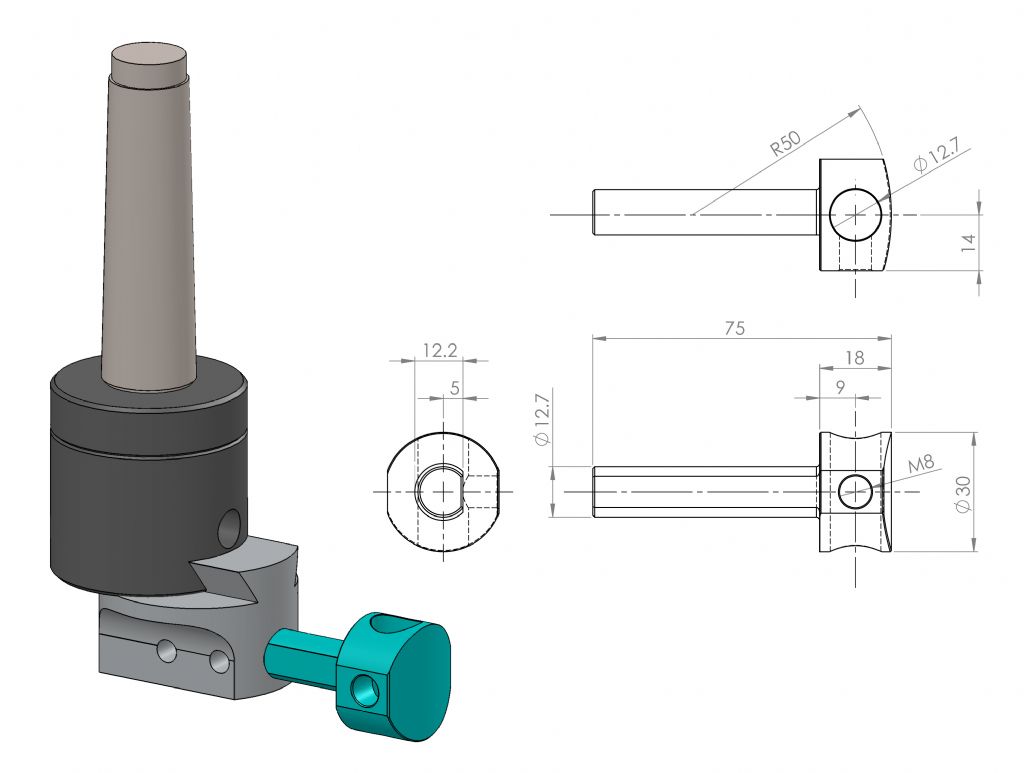

You can get RH and LH boring bars, and even double-ended ones. The type supplied with the head are correct for vertical operation in the boring head and for most lathe-work.

I've run my boring head in reverse and not had the drawbar come undone on a mill with an MT spindle. If the drawbar is tightened enough for the taper to grip properly, it shouldn't unwind.

Possible Perspex contributed. It's on my list of difficult materials. It needs a sharp cutter and it's important to make sure the plastic doesn't melt and stick. I once ran a jig-saw through a sheet of Perspex only to find the two halves welded back together behind the blade.

I wish I knew a way of tightening drawbars scientifically. I do mine by feel, first hand-tight, then spannered to close up with two fingers, plus a 1/4 to 1/3 hard turn to nip up. Seems to work well enough – the taper releases after a single sharp tap, and doesn't spin. But what on earth I mean by 'spannered to close up with two fingers' is probably only meaningful to me – pretty unhelpful!

I suggested in a recent thread that R8 might be more likely to slip than MT2 because the R8 taper has a smaller surface area. No proof though! Perhaps Ian has hit the problem in the real world?

If I bored lots of big holes I'd buy a Left Hand boring bar.

Dave

Howard Lewis.