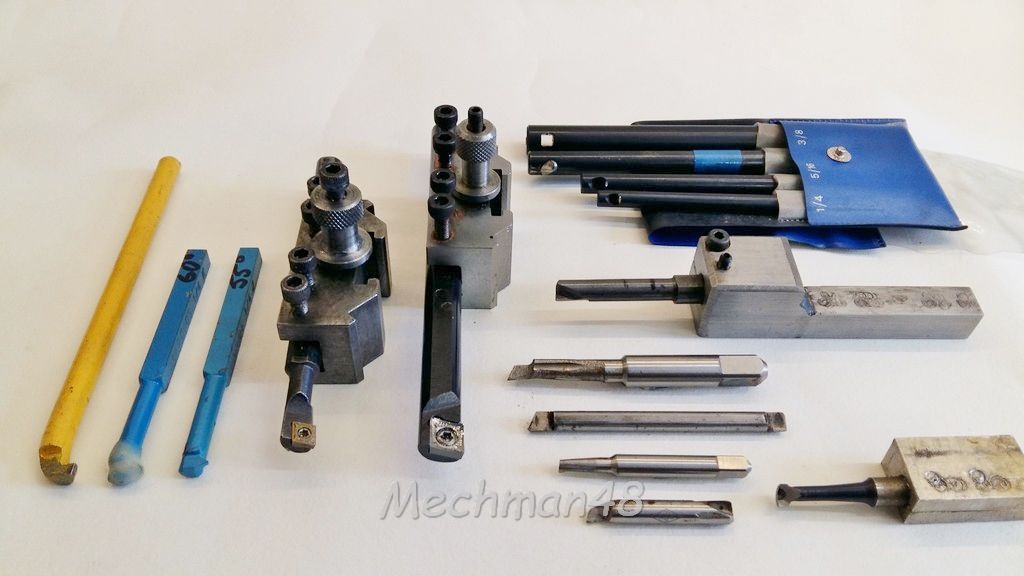

I'm blessed with more boring bars than you can shake a stick at.

One of my favourites is made from the bent and ground end of a broken drill, jammed in a bit of aluminium extrusion. It's excellent for straight and tapered holes down to about 1/4"

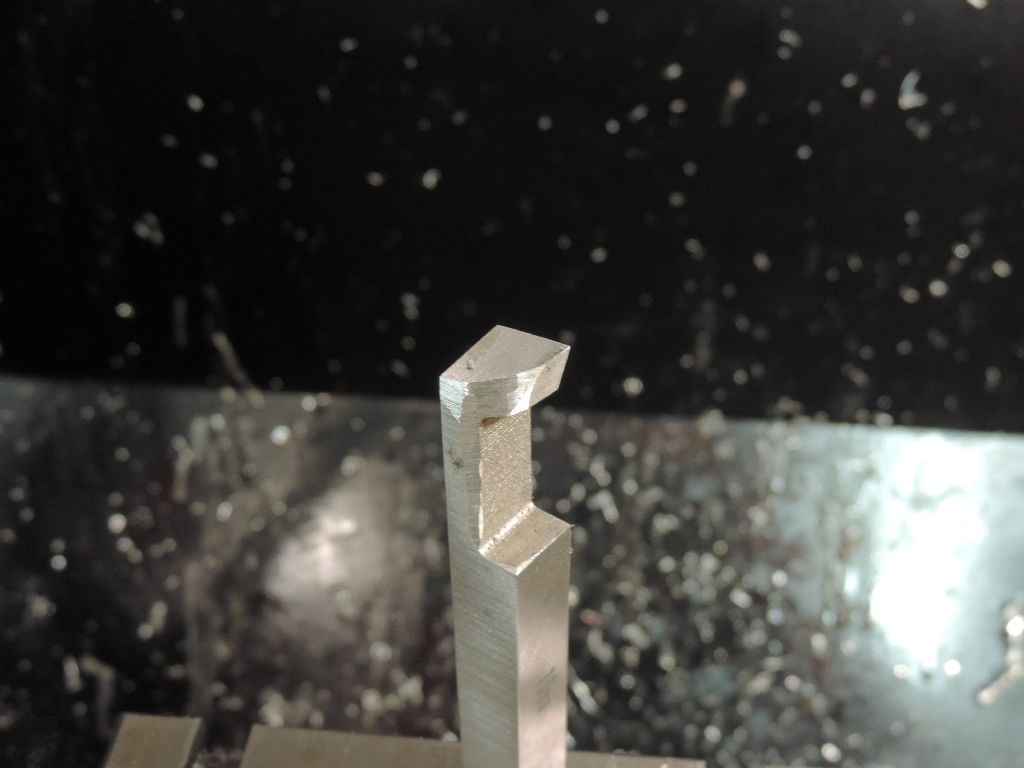

The boring bars that come in HSS sets are generally of two types. The square shank ones are easy to use, with the same shim, as other tools in the set, but need to be ground away for clearance in small holes. 8mm tools will just about work in a 16mm hole with this treatment.

Round shank boring bars need less grinding, but are harder to set. It can be better to use a big bar straight in the toolpost without its square holder, than to use an undersize bar with a big overhang.

I also like the bars that take a tiny 1/8" HSS insert in a 3/8" or 10mm shank. These work well with mini lathes, bit you may have to grind a curve on the fixing screw to get in small holes.

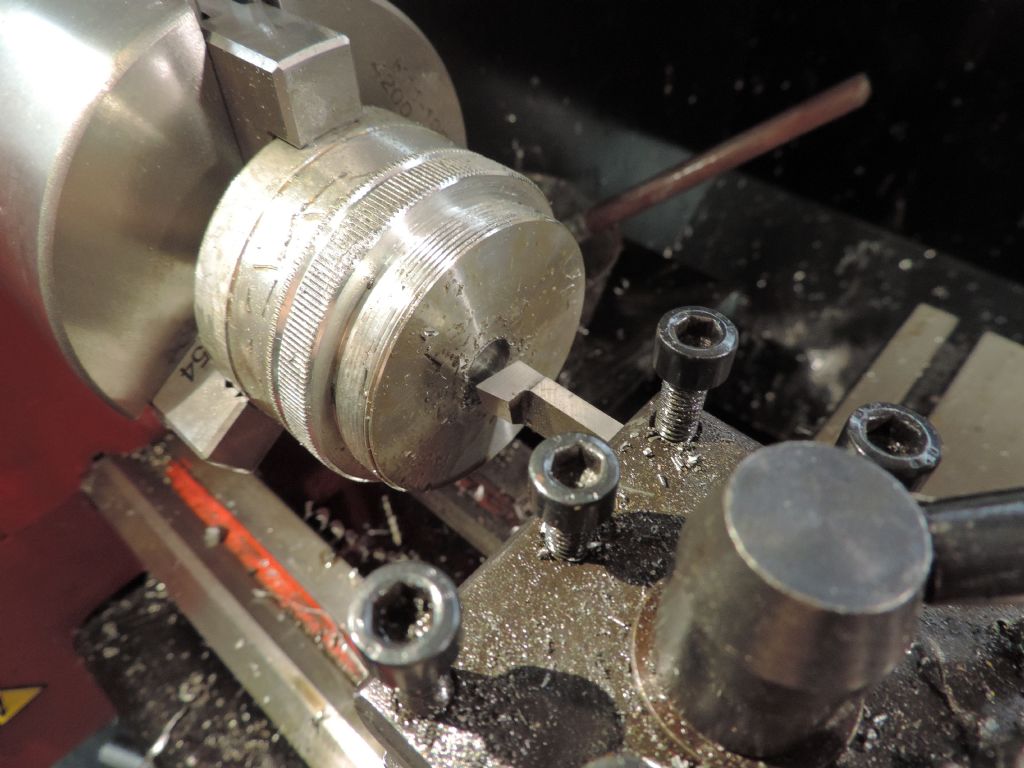

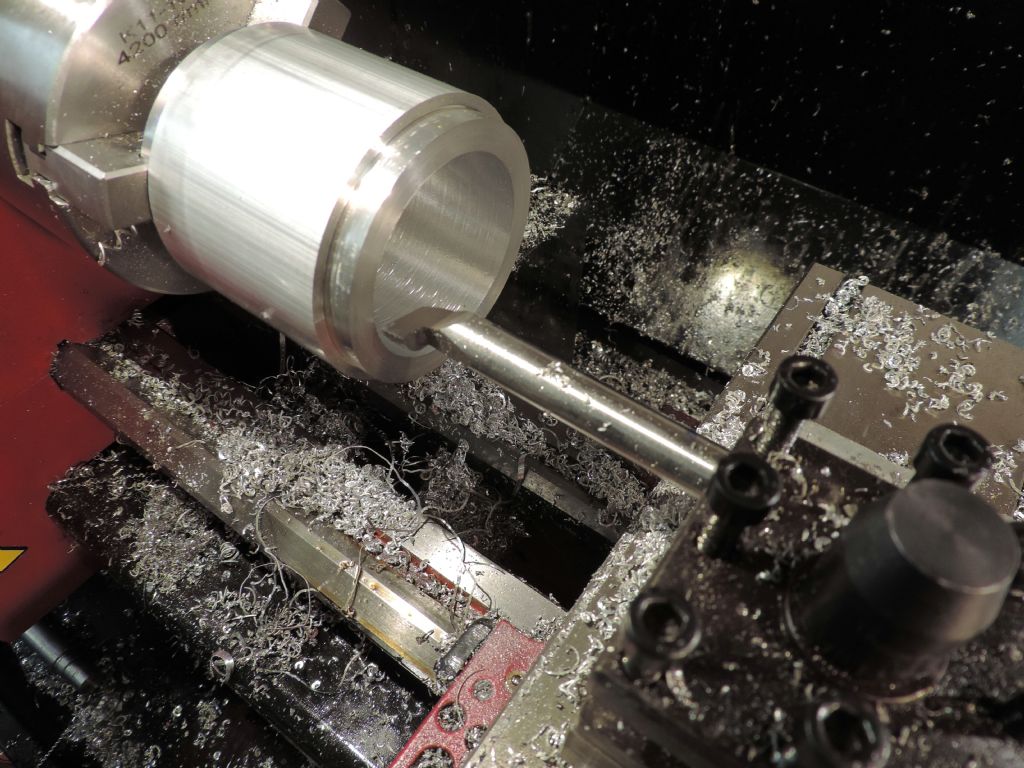

My new favourite boring bar is this S10K-SCLSR06 from Arc. It takes CCGT/CCMT inserts. It has flats on it so the insert 'droops' at about 20 degrees which seems all wrong! With a hefty bit of packing (about 2.5mm) it's cutting rather below centre height in the SC4 toolpost. Not sure how the mini-lathe would handle it.

Overhung by the thick end of 3" I had to limit cuts to 0.4mm in 6082 alloy today, but even with a CCMT insert (and a dab of cutting fluid) it was very free cutting with excellent finish.

Obviously a QCTP with much more latitude in setting height will bring me closer to boring bar nirvana on the SC4 but so far I've largely stuck to the 4-way toolpost.

Neil

Alan Vos.