If your model is to be insured and steamed in public, should it not be the case of establishing what design stress, joint factor and safety margins are acceptable to the boiler inspector and insurance company. Then the design can be worked out to meet their requirements and subsequently approved by them. In other words what code of practice do they accept?

Although you have done some testing to justify to yourself the safety of your design these are unlikely to be taken into consideration by your boiler inspector or insurance company unless very well documented and maybe also witnessed.

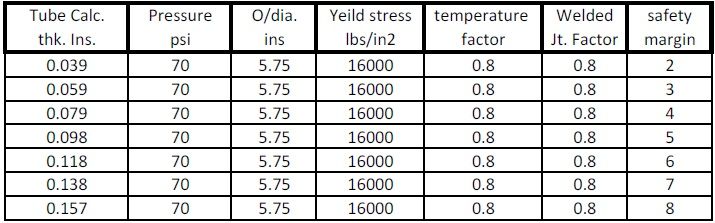

I am not familiar with the formulas stated above, the following table shows calculated tube thickness using a standard hoop stress formula (also typically used in pressure vessel codes). I have used some values suggested above for yield stress and joint factor and included a range of safety margins for comparison. Normally you would establish a design stress based upon material mechanical properties and operating temperature and use this in the formula.

Other considerations concerning boiler tube thickness will be a) does the boiler tube support any other significant structures like cylinders etc. b) what reinforcement is applied to openings/nozzles.

One method concerning openings/nozzles is to use an 'area replacement method', basically you take a section through the opening/nozzle, calculate the area of material removed then ensure that any reinforcing ring has at least the same section area. If the boiler tube is thicker than theoretical then the extra thickness above theoretical can be included in the calculation, for example, if the theoretical thickness is 0.05" and the actual thickness is 0.15" then there is a good chance that a reinforcing ring is not needed as the actual tube thickness already has sufficient strength. There is a specified method for determining the width of any reinforcing ring, I would have to look this up.

Here's a useful source of information.

I hope this is useful info.

Nigel

Crabtreeengineer.