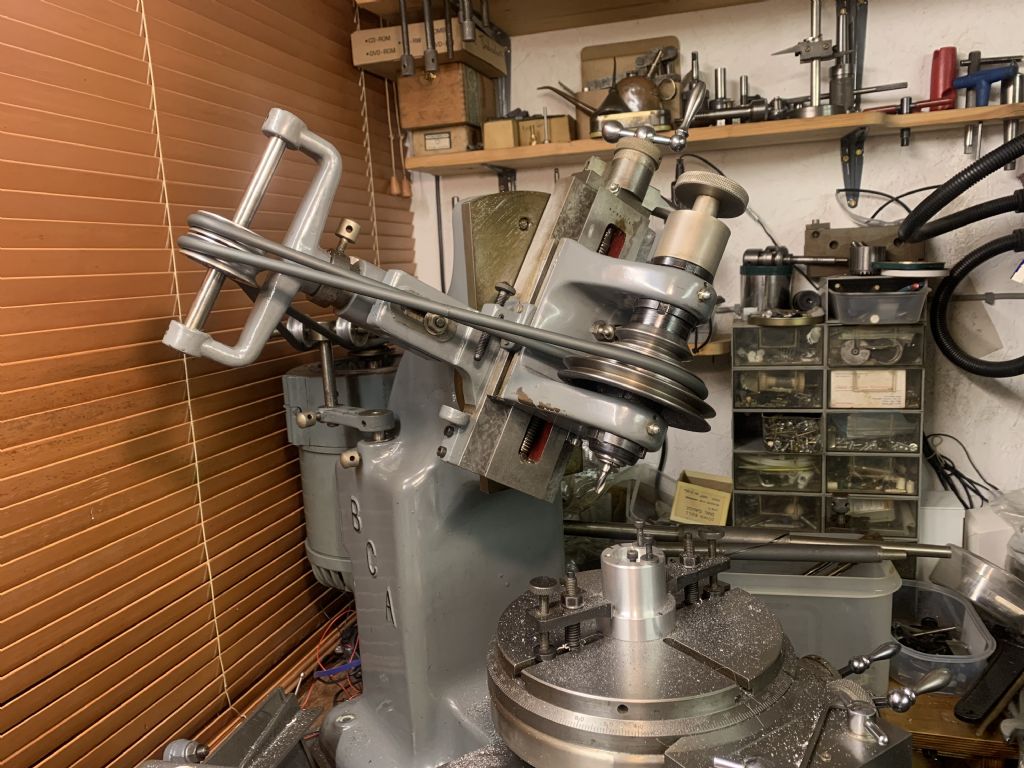

I have one of these (that a bit of Dorset Echo in one photo..? .) and I must admit that the rear pair of pulleys confuses me, though I notice you have the belt passing under them in one or two cases. On my machine the belt usually runs clear of them, but in any case they never seem aligned at the belt angles.

Mine came with a rather dubious inverter to power its original motor so I replaced both with a new motor and controller (Newton Tesla) but I was careful to fit the original pulley, and in its original location including height. I had to make an adaptor plate for the task.

Nevertheless, whether those jockey pulleys do any jockeying seems to depend on their mood at the time, and I am not sure if that is natural.

I am not convinced either, that the tensioning spring does much, but I have noticed that even when the tensioner is out at its maximum, the belt rubs slightly on the body of the machine if used on the lowest speed spindle pulley.

I suppose it's possible the belt on my BCA has stretched with age. I've not tried asking Tenga if replacements are available but if their collet prices are a guide, they won't be cheap!

Steve Wan 1.