Posted by IanH on 01/08/2018 21:51:31:

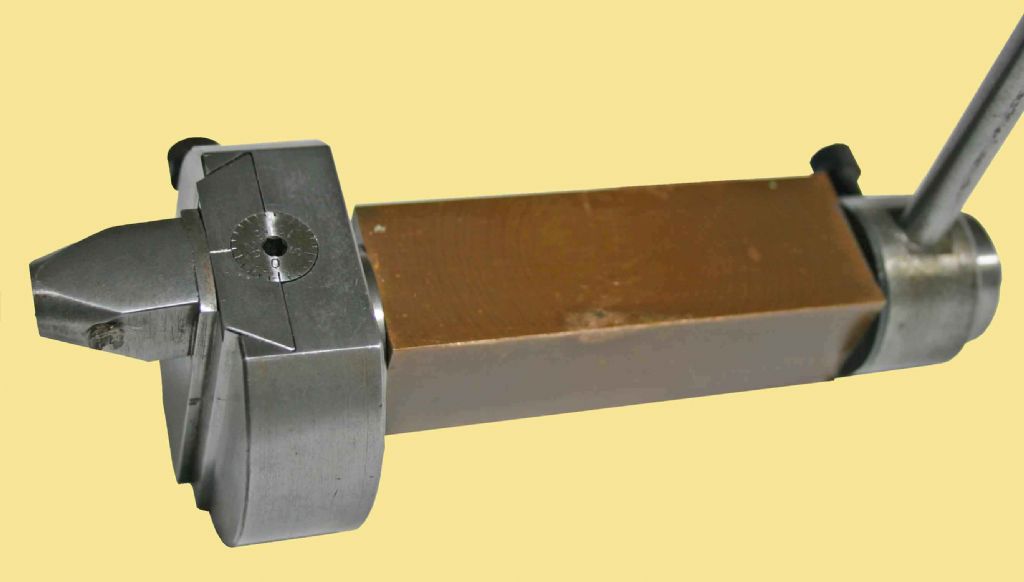

I use a small/miniature commercial boring head bought at an exhibition mounted horizontally in a tool holder.

Another approach that might appeal if you are making a number of balls to the same diameter is to bore a piece of silver steel bar to a diameter 0.7 times the diameter of the ball you are aiming for. Then turn a chamfer on the outside to give a sharp edge. Harden and temper.

Rough turn the ball, then use the tool you have just made by hand to finish the ball. There must be something on the web that shows this if you have a root around…

Ian

Edited By IanH on 01/08/2018 21:52:30

Thanks Ian Both interesting ideas just been watching videos of the boring bar attachment to see how that would function. will see if I can find one of the other method you mention

Posted by NZreg on 01/08/2018 22:45:17:

You might consider a Turnado from Eccentric Engineering, see advert to the right of this page

You know what, I saw that thing earlier this week whilst trying to find a solution and thought it looked marvellous I had no idea you could freehand a tool on a metal lathe, like wood turning and that really appeals to me for certain applications, However, I think Michael is probably right. I went and took a look at my Cowells after checking out Turnado videos and forgot how little room to manovere I've actually got 😀

Sam Stones.