From John:

Either (a) you are going o use this element in which case it doesn't matter; or (b) you want to make your own.

If (b) why worry about what wire was used originally? Just use somewhat thicker copper, possibly silver plated, but frankly at 13 MHz it won't make much difference given that you want most of the loss to be in the thing you heat.

John, I would use it but its a little short for what I am trying to do. Point is that Metcal by induction generate 40 to 50 watts into the tip, without cooking the wire , no tarnish, no oxidation. The wire is insulated with a very open weave fibreglass sleeve when coiled around the nickel/copper slug at the tip, so that would lessen oxidation to some extent, but the weave is rather open so is exposed to hot air. I have been playing with peralin coated copper wire, as well as kapton coated copper – it cooks…. I tested this by winding an identical copper wire coil in place of the Metcal wire and running it on the metcal tip and power source.

From Robert :

Is this a genuine Metcal tip?

Well,… Yes – since its my Metcal iron and the tips I purchased from OKI International – Tip in the photos is a STTC-135

Last time I took one apart it used Litz wire. That was several years ago though. Has th bit been used? migh seem obvious but if it's not been used much it won't have oxidised much.

That must have been long ago – Litz wire was used in the SP-200 system ( over 15 years ago..), which ran at 475KHz – quite different,

From Andrew:

I'd agree with Michael, platinum is way too expensive. Fair point by SoD about skin depth, although silver does tarnish in the atmosphere so the wire may not be simply plated. From a simplistic viewpoint the intent of induction heating is to transfer energy to the workpiece to heat it up. Any heating of the primary coil is wasted energy, so I would have thought that the primary coil wouldn't be designed to get hot?

Andrew, that is the key here, and exactly what I am trying to discover how its achieved – The tip gets hot, but the wire is never hotter than the tip – Measuring the AC current in the coil while heating the tip ( using an old, good, HP current probe..) I read around 1.2amps RMS. The voltage across the coil is around 200volts PP. That magnetic field then generates eddy currents in the nickel mix cladding on the copper tip and heats it. But the wire does not cook. If I replace with copper wire, the current actually drops to 1.05amps, but the coil cooks after a while – I suspect the skin effect is killing the coil.

I begin to think the wire is silver – Pricing also reflects that – around 18 Euro for a meter…

And last, in one of the Patents I read, It is indicated that the wire can be Silver, copper, or nickel/copper….

Reading patents – to do much of that requires a special kind of person…

'said means of multiple claimed pluralities causing substantial crossing of the glazzies'..

Joe

Photo shows the coil in its glassfibre insulation, the tip heating slug right, and the bare wire on left.

Coil zoomed in

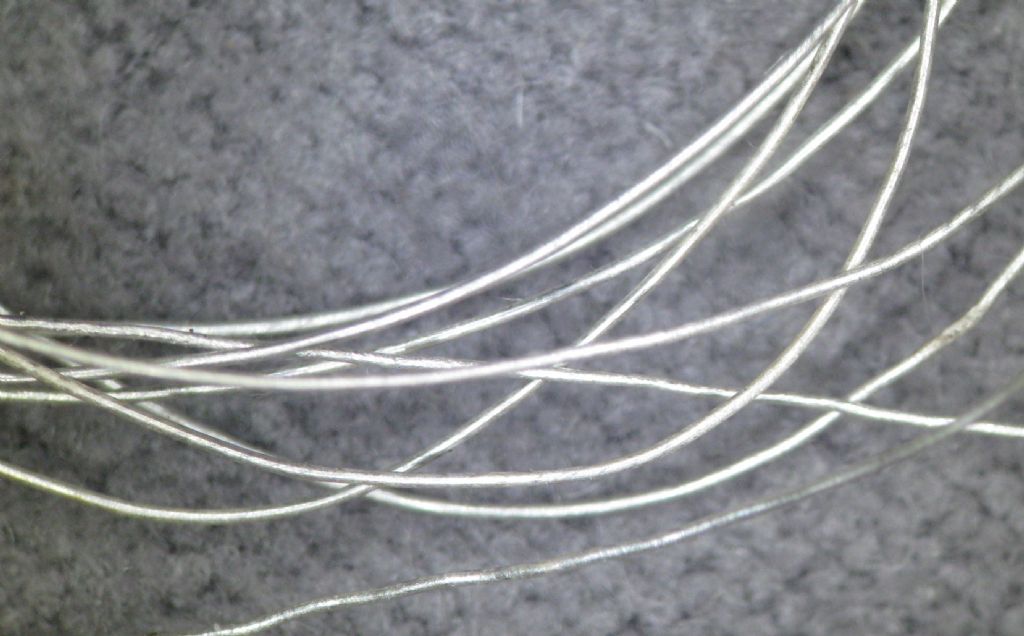

Bare Wire from a VERY used hot grade tip

Joseph Noci 1.