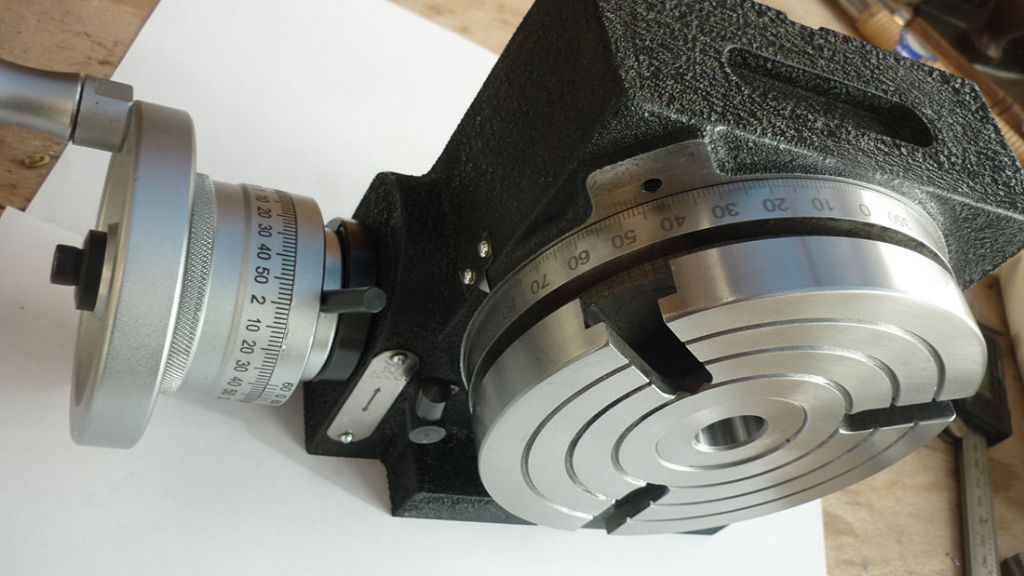

Hi, Mark – apart from the shape of the block, the bits of my table look exactly like yours. I don't have the big cutout in the eccentric cylinder for the handle/worm grubscrew location – mine is just a shallow groove all the way round the cylinder.

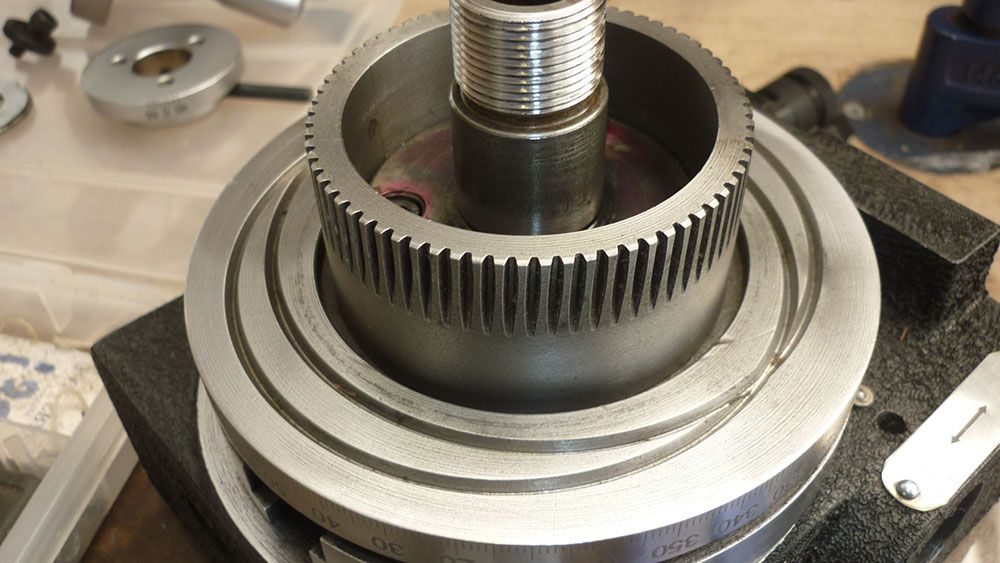

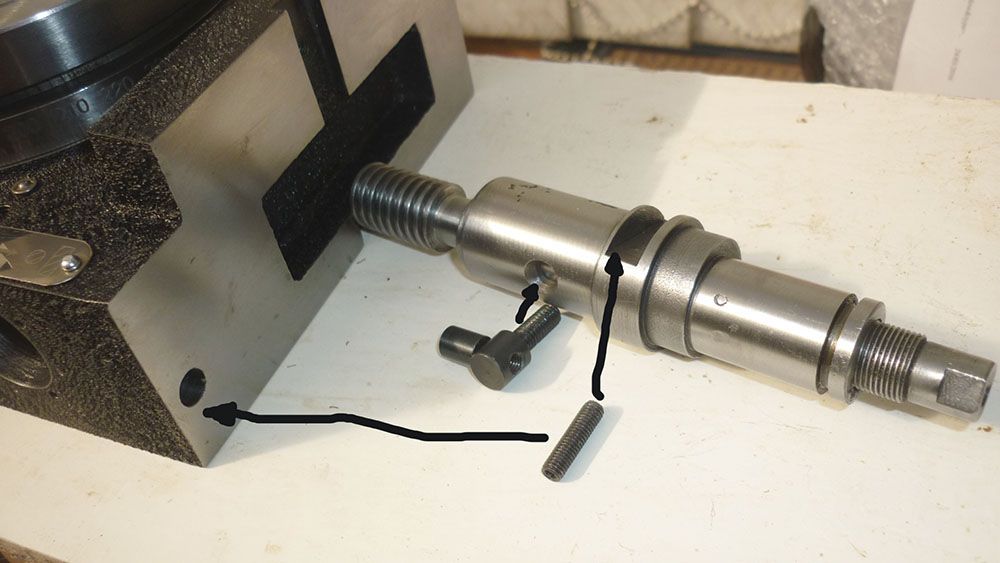

I also got no instructions. (Suspect Chinglish would have been hard to follow anyway). When I reassembled mine, I gently turned the entire eccentric handle mounting cylinder (Don't know what else to call it), until I could feel that the worm was engaged with the table gear (turn the handle a bit), then adjusted it until I could fell no backlash in the handle or by trying to turn the table. I don't know if this is correct, but lack of instructions…. After I had used it for a while, I repeated this process, as it seemed to have 'bedded' in or settled down a bit.

I assume yours used to work before you dismantled it, so the handle should fit back in approximately the correct position because of the slot for the grubscrew, so you should only have to turn it a short way to get the correct position. Since I set it up like this, it has worked fine – no perceptible backlash.

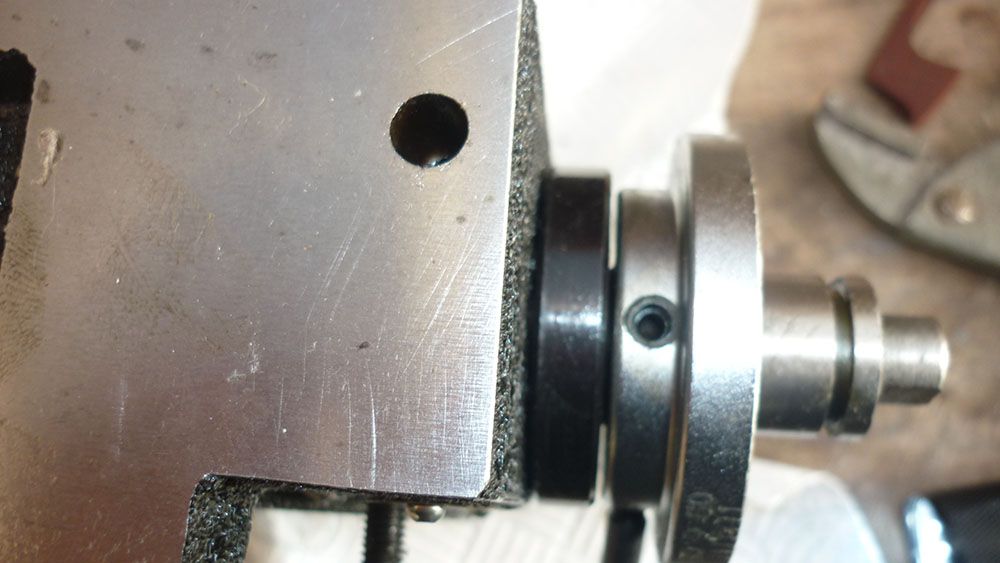

I suspect the big slot is to allow some In/out adjustment as well as rotary adjustment, so a slot would be cheap and easy to machine. I can't adjust mine in the In/out direction: it must fit fully home so I can get the grubscrew to locate in its groove. Check the grubscrew is OK – threads and hexagon – be a shame to get it back together only to find later that the grubscrew is knackered.

If you find things are touching that shouldn't, try putting it together 'one piece at a time'. Fit the table without the handle, and ensure that it rotates freely. If that is OK, then push the handle into place, and ensure it all turns freely and smoothly before tightening the grubscrews and locking screws. I don't know if it correct, but I used some grease on the worm/table thread (didn't like the idea of it turning 'dry' , and thin oil on other bearing surfaces. Maybe someone else some advice on this.

, and thin oil on other bearing surfaces. Maybe someone else some advice on this.

Sorry about the 'technical' terms – I can make it work, but I don't know what the bits are called, so I hope you can follow my description.

Edited By An Other on 30/03/2016 19:45:58

Michael Gilligan.

Michael Gilligan.

, and thin oil on other bearing surfaces. Maybe someone else some advice on this.

, and thin oil on other bearing surfaces. Maybe someone else some advice on this.