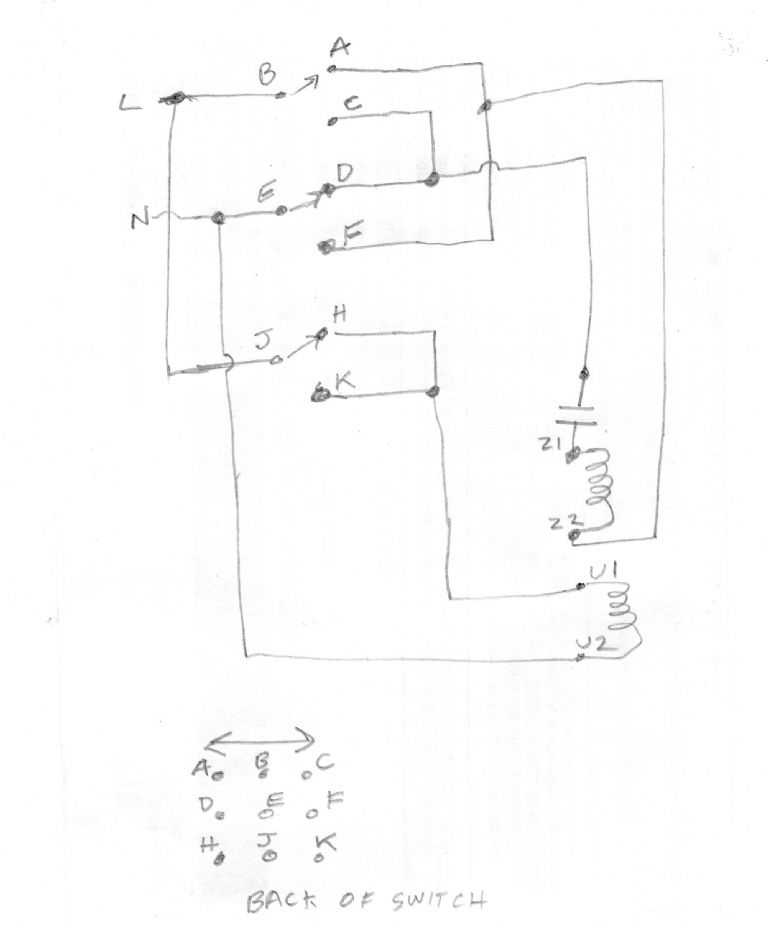

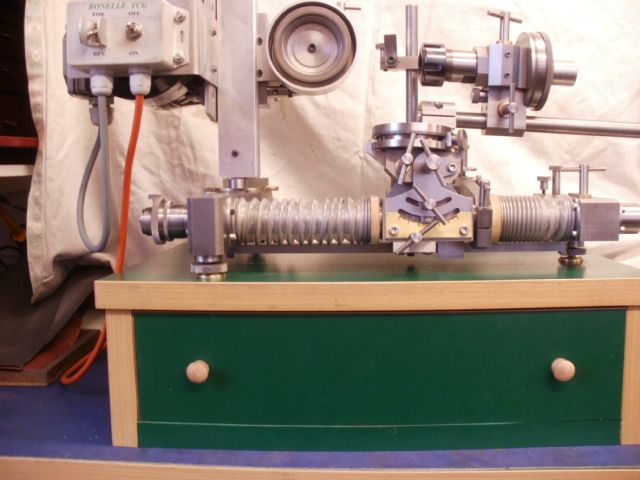

Another motor reversing cry for help

Another motor reversing cry for help

- This topic has 20 replies, 8 voices, and was last updated 3 February 2015 at 20:15 by

Les Jones 1.

Viewing 21 posts - 1 through 21 (of 21 total)

Viewing 21 posts - 1 through 21 (of 21 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

Viewing 25 topics - 1 through 25 (of 25 total)

Latest Issues

Latest Replies

- How to remove this milling machine saddle?

- Aircraft General Discussion

- New Member – looking for a Myford Super 7 (I think!!)

- Stationary Pamphlets

- Camshaft machining by milling

- Drive belt for small Chinese pedestal drill

- Midlands Model Engineering Exhibition 17th – 20th October

- Fire Extinguisher for the workshop?

- Unimat3 vs. Sherline lathes

- Thread cutting tolerances ?