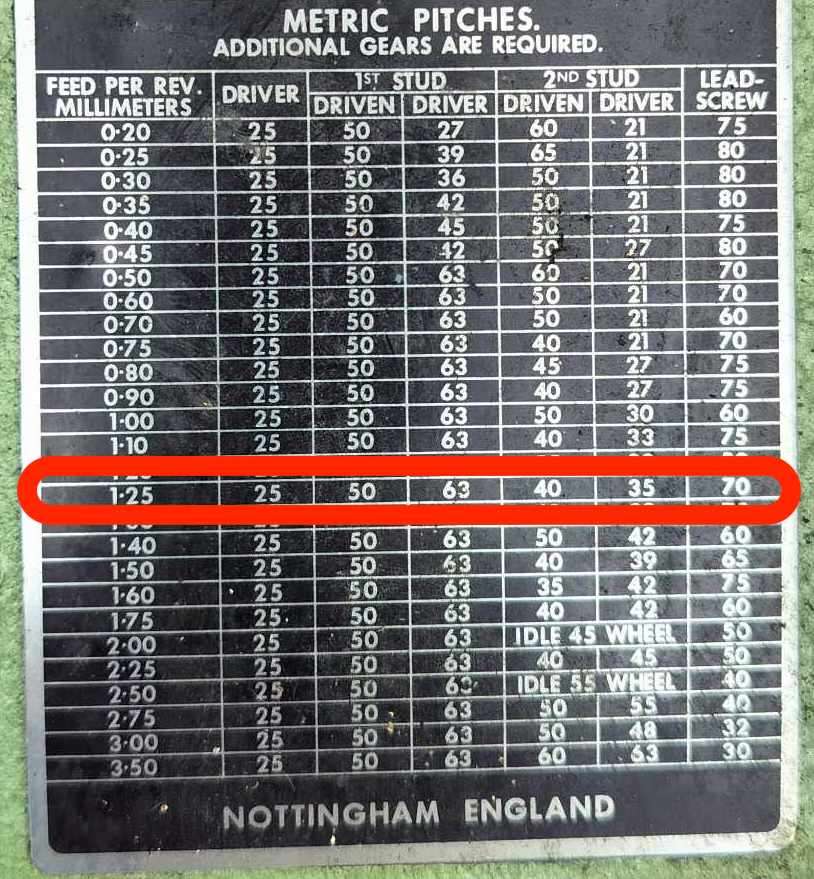

If the chart calls for a 63T gear, that suggests that it has an Imperial Leadscrew.

Have you carefully checked the pitch of the Leadscrew? (What are the graduations on the Cross Slide and Top Slide handwheels? If they are Imperial, the chances are that the Leadscreww is also Imperial; possibly 16 tpi. If need be, check, Engage the half nuts, Take out the backlash, and them set a DTI to zero and measure how far the Saddle moves for 5 or 10 revolutions of the Leadscrew. A simple calculation will tell you the pitch of the Leadscrew. The answer is likely to be 0.0625″ if Imperial, 1.5 mm if Metric.

If the graduations are Metric, than the leadscrew might well be 1.5 mm pitch.

If your machine had a 1.5 mm pitch Metric Leadscrew, to cut a 1,25 mm pitch thread, you would need to set up a gear train where the Leadscrew rotates 1.2 times slower than the chuck. (According to the chart for my mini lathe, a possible changewheel set up would be DRIVER 50T, IDLER 40T, LEADSCREW 60T.

IF your machine has an Imperial, 16 tpi Leadscrew, you would need to compound the 63T gear with the 40T IDLER, using spacers to bring all the meshes into line.

If this IS the case, and you need a 63T gear, you should be able to buy one, in Aluminium alloy, from Arc Eurotrade

Carefully measure before doing anything!

Martin Ckeeve’s book,”Screwcutting in the Lathe” is No. 3 in the Workshop Practice Series.

For a 1.25 mm pitch thread, he quotes FOR a 8 tpi LEADSCREW

35 – 50

45 – 40

30 – 60 He says that this gives an error of +1 in 8000

Or alternatively

45 – 55

50 – 40

25 – 65 He says that this gives an error of -1 in 1144

So you would need to change at least one of the wheels to suit a 16 tpi Leadscrew, so that it rotates twice as fast, relative to the chuck, as it would for a 8 tpi Leadscrew.

Change the 40T to a 80T driving the 30T, in the first example? Check my arithmetic!

Another book that may also help you is Brian Wood’s “Gearing of Lathes for Screwcutting”

HTH

Howard

mark costello 1.

mark costello 1.