Amplifier Repairs..

Amplifier Repairs..

Home › Forums › The Tea Room › Amplifier Repairs..

- This topic has 24 replies, 10 voices, and was last updated 5 December 2019 at 12:06 by

mark smith 20.

-

AuthorPosts

-

3 December 2019 at 09:17 #35685

Joseph Noci 1

Participant@josephnoci1A nicely made Amplifier repaired

3 December 2019 at 09:17 #439956Joseph Noci 1

Participant@josephnoci1For Brain Food I repair musical equipment for our local Music Shop – A nice one came in yesterday. Very nicely made by Mesa Engineering, Hand Assembled in California! Was a pleasure to work on. A simple repair – a large 3.3uf 600v polypro capacitor had broken one leg – it was the only cap not bonded to the PCB, and being a good combo/base amp, the vibration took its toll.

A really nice sound, hard to distinguish from really good Fender and Marshall bits of old..2 x 6L6's in the output, a nice 50watts.

The metal chassis has every open seem tig welded, every edge and corner de-burred and smooth. Every wire nicely laced and tied.

Thought this did not happen anymore in the real world.

3 December 2019 at 09:46 #439964 Mike PooleParticipant@mikepoole82104

Mike PooleParticipant@mikepoole82104Looks a beautifully made unit, well respected for its sound as well. Having looked in a few hifi audio amps they often seem to just birds nest the wiring, the justification seems to be that it reduces crosstalk pickup however Quad must be immune from this as they have beautiful neat wiring. Could it really be a cost saving measure or design shortcut?

Mike

3 December 2019 at 10:46 #439978SillyOldDuffer

Moderator@sillyolddufferPosted by Mike Poole on 03/12/2019 09:46:01:Looks a beautifully made unit, well respected for its sound as well. Having looked in a few hifi audio amps they often seem to just birds nest the wiring, the justification seems to be that it reduces crosstalk pickup however Quad must be immune from this as they have beautiful neat wiring. Could it really be a cost saving measure or design shortcut?

Mike

It is well made, and no doubt reassuringly expensive, but Mesa's sales-talk rings alarm bells!

I looked them up in hope of finding out exactly what "Single Rectifier® – Series 2 Rectoverb®" might be. I did find:

"We keep saying it, but it’s hard to overstate the value, effectiveness and stylistic “power” of the Multi-Watt™ Channel Assignable Power switches. These dedicated wattage range choices unveil different power characteristics and colors – so they are really power “voicing” switches as well.

In this Recto®, the choice of EL-84 power tubes with their amazing clip characteristics, prompted us to explore the different wiring schemes possible. This experimentation led to the 10-Watt Power Mode being wired for Triode operation. This “more vintage” wiring scheme sweetens and rounds out the sound, turning what might otherwise be a lower volume version of the same voice, into more “soulful” Recto experience.

The 25-Watt setting delivers a bold attack, tight tracking low end, increased definition and all out headroom. This setting works great with all the sounds and certainly showcases the mightiness in this little Rectifier®, shocking unsuspecting players and bystanders alike with power and sonic size. But any time you need to tame this little beast and put a vintage patina of warmth and silkiness around things… kick down to 10-Watts and enjoy a whole new and different world of Recto expression."

I apply the "need to tame this little beast" every time I use my lathe, which also has a "vintage wiring scheme". Turning too fast, the cutter is unlikely to achieve the "silkiness" I want in the finish, and run for maximum chatter my lathe is also able to shock unsuspecting bystanders with its 'sonic size'. The lathe works much better when I manage speed with the hand-fitted Polybutylene Succinate isolated and carefully matched Carbon Track Potentiometer. Ignoramuses only see an ordinary speed control knob.

The presence, or not, of a wiring loom, is no indicator of quality or cost. In a car, for example, it's much cheaper to make up looms on a board and fit them as a whole than it is to individually run wires through a finished car. Lots of other advantages, the loom can be routed to avoid damage and firmly fixed to resist vibration.

In electronics, looms are often avoided like the plague. At higher frequencies, looms have significant inductance and capacitance and they are highly prone to cross-talk. A 1940's valve radio will typically have looms and parallel tags for power and audio, but short direct wiring in all the high frequency circuits.

Frequency-wise, audio amplifiers are in border territory. A cynic might suggest this accident of physics allows makers to cater for customers who believe neat tidy looms produce the best sound, and customers who believe short direct wiring must be the bees-knees.

Engineers like to wire stuff up to avoid cross-talk, distortion and parasitic oscillations… They also know that amplifiers are imperfect compromises, that most people don't notice 5 to 10% distortion, and that audiophiles perform badly in double-blind sound tests. In engineering, functionality is all that matters. Or is it?

Rather a lot of engineering is devoted to status, everything from Smart Phones to Space Travel. It pays the bills and fuels development. Audio-mania isn't completely bonkers – it meets our social need for togetherness and hierarchy. The need to be a member of the group stops me going to funerals dressed as a clown even though the suit keeps the weather off perfectly well! And the same group rules expect the Vicar to wear a dress…

Dave

Edited By SillyOldDuffer on 03/12/2019 10:49:54

3 December 2019 at 11:08 #439982 Ian PParticipant@ianp

Ian PParticipant@ianpI fully concur with everything Dave said.

Ian P

3 December 2019 at 12:02 #439993Joseph Noci 1

Participant@josephnoci1Huh????

I have repaired many a 'Fender' and 'Marshall' of recent 'vintage' ( Peavey as well) and can only say that digging around in those was never a 'pleasure' – Most who buy today's Fender's and other makes of similar ilk, do spend a fair amount on them, so I would have thought that the manufacturer could up the build quality in keeping with the name – their customers could afford it..

early this year I repaired a Fender BassBreaker 30R (4xEL84 in the output) . Needed to replace 2 of the EL84 valve bases – and one EL84 that I broke(!) – removing the spring clip that pulls the valve into the base, two valves just fell out of the base! The first caught me by surprise and fell onto the speaker magnet…The valve base contacts did not contact the valve pins anymore…The 30R is a new amp, very recent mnfr..made in China.

Why was I removing the valves to start with – I always do that first, so that I can remove the amp chassis from the cabinet without inadvertantly breaking a valve….

The Sales pitch Mesa applied is nothing new – go read a little on the Fender web site and see their version of the speed control knobs..

Marshall's language follows suit, and so does that of all 'good' amp vendors.

Marshall does, however, also make some very nice amps – particularly the HandWired series, and the 1974X, which has no PCB, is point to point wired, and very neat and easy to work on. Sounds great too!

J

3 December 2019 at 12:21 #439997 Mike PooleParticipant@mikepoole82104

Mike PooleParticipant@mikepoole82104Allegedly VOX chucked an AC30 down a flight of stairs as a demo of robustness, and it worked when they powered it up, may be true but I wouldn’t put my money on a valve amp working after a test like that but sometimes you get lucky. Legend has it that most of the Marshall cabinets in the back line of a band like Motörhead are empty apart from a red light. Keeping a touring rig working must be never ending job.

Mike

3 December 2019 at 13:26 #440011Brian H

Participant@brianh50089Looks to be nicely made.

In another life, in another age, I was a DJ and knew a member of a Nottingham band who worked at Carlsbro who made amplifies. He made me several 400 amp amplifiers over a period and even went to the trouble of hand winding coils with exactly the correct number of turns. They were wonderful amps and the mention of EL84's made me remember.

The then bass guitarist from Status Quo was particularly impressed with a 400 watt amp driving a set of 18 inch Goodmans speakers, I had to make sure they were loaded into the correct van after a gig.

Brian

3 December 2019 at 17:54 #440058 Neil WyattModerator@neilwyatt

Neil WyattModerator@neilwyattMesa/Boogie amps are very good. Whether Fender or Mesa is best is very much a matter of taste not objectivity. These Americxan amps tend to be louder and cleaner sounding than British ones like Marshall, Vox, Orange. (Often characterised as 6L6 vs EL34).

Posted by Mike Poole on 03/12/2019 12:21:34:Allegedly VOX chucked an AC30 down a flight of stairs as a demo of robustness, and it worked when they powered it up, may be true but I wouldn’t put my money on a valve amp working after a test like that but sometimes you get lucky. Legend has it that most of the Marshall cabinets in the back line of a band like Motörhead are empty apart from a red light. Keeping a touring rig working must be never ending job.

Mike

A Vox AC30 combo is louder than a Marshall 100 watt valve amp on a 4×10 cab

In practice, loom-wired amps are more robust than PCB one., at least for valve amps. more tolerant of thermal and other stresses.

The difference between wiring a pentode and triode amp should be noticeable, and there are lots of ways to 'tune' valve amp circuits for different tones and behaviours.

Differences between amps are marked, I have a Vox modelling amp with 33 different amp models… it uses digital modelling but STILL has a valve stage that it uses to produce part of the sound of some amps.

Anotehr example I tried out a very nice bass last week – on a Markbass Amp (clean, bright slappy oriented) its bridge pickup sounded rather poorly, swapped to a Fender Rumble with a more 'vintage' tone and it sounded excellent, back home and it sounds great on my Orange Crush practice amp. Note that I kept the tone settings pretty neutral on all three (transistor) amps.

Neil

4 December 2019 at 04:46 #440126Danny M2Z

Participant@dannym2zSo why do the M.E's get all the amplifier jobs?

Here is my latest, a Marshall Valvestate 2000 that blew the output FET's when it was placed in front of a flexible plastic screen that got sucked into the twin fans at the rear (at least that's what my detective work deduced).

The replacement 100W FET amplifiers arrived promptly from the USA but the owner was required to sign a declaration that the parts were for repair only and not to be re-exported to a 3rd country???

As the owner is a good mate who does gigs for extra income I took on the job but no more amplifiers please, I want to play with my lathe.

In deference to Marshall, at least they had the decency to place the circuit diagrams online (well somebody did) and there is a forum dedicated to these amplifiers.

* Danny M *

Edited By Danny M2Z on 04/12/2019 04:46:56

4 December 2019 at 06:33 #440131Joseph Noci 1

Participant@josephnoci1Danny, of which series is the Valvstate 2000? I know the Valvestate 20 series, and the various models in the 200 series, but not any 2000's..

Did you get the parts from DigiKey? I obtain a lot of electronic parts for our wildlife tracking collars from them and the Declaration of use is standard with most American component suppliers – including Mouser USA, but not Mouser UK..

Interesting names the amps get – 'ValveState' and Peavey's 'TransTube'…

Nice Guitar Neil!

J

4 December 2019 at 11:16 #440186SillyOldDuffer

Moderator@sillyolddufferPosted by Neil Wyatt on 03/12/2019 17:54:14:Mesa/Boogie amps are very good. Whether Fender or Mesa is best is very much a matter of taste not objectivity. These Americxan amps tend to be louder and cleaner sounding than British ones like Marshall, Vox, Orange. (Often characterised as 6L6 vs EL34).

…

The difference between wiring a pentode and triode amp should be noticeable, and there are lots of ways to 'tune' valve amp circuits for different tones and behaviours.

…

Differences between amps are marked, I have a Vox modelling amp with 33 different amp models… it uses digital modelling but STILL has a valve stage that it uses to produce part of the sound of some amps.

…

Neil

Sorry if I upset Joe by drawing attention to sales speak earlier but I'm genuinely interested in the relationship between engineering, psychology and our addiction to 'quality'. I put 'quality' in quotes because – on its own – the word has no meaning in engineering. All too often on the forum 'quality' means much the same as 'nice', a word forbidden at my school because it's lazy and meaningless. Quality can only be judged relative to a specification. Anything else is just a matter of opinion, which can be right, wrong or lunatic!

As an engineering artefact, I suggest the perfect amplifier is one with zero distortion, that is the output waveform is identical to the input apart from being louder. An amplifier shouldn't sound 'cleaner', 'brighter', 'slappy', 'vintage', or add any other characteristic to the sound whatsoever.

I think of it this way. The performer, musicians and recording engineer go to a great deal of trouble in the studio translating a composers inspiration into a work of art. Their conception is what the listener should appreciate, not their ad-hoc interpretation. Dare I suggest buying an amplifier that modifies the result is akin to improving the Mona Lisa by adding a felt-tip moustache?

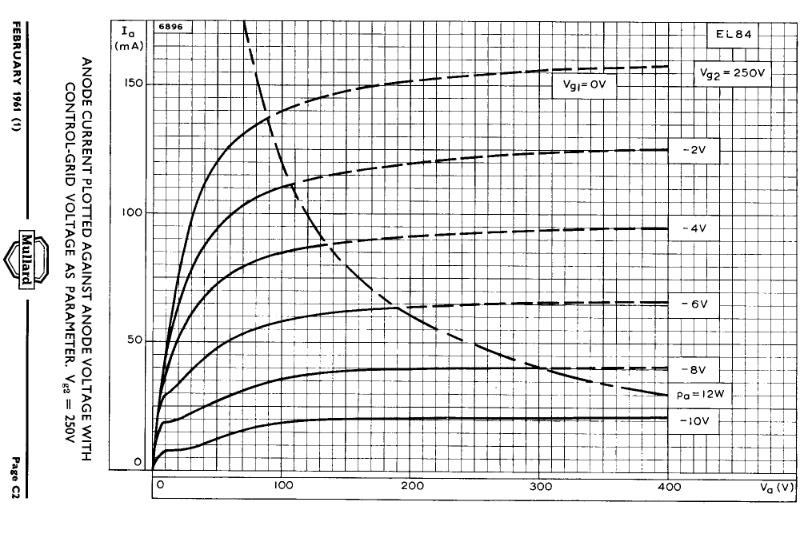

Valves, like transistors, are imperfect devices. Ideally the characteristic curve would be a straight line; they aren't. Curves and kinks are what the designer has to work with:

In the EL84 example above, the curve is drawn for a range of anode voltages. This is important: while the designer can design the amplifier to operate more-or-less linearly under ideal conditions, his efforts will be undermined if the power supply sags under load. As stiff power supplies for valves are expensive, this aspect is often compromised. If the listener finds the effect pleasing, the audiophile isn't enjoying the original, he's being pleased by a cheap power supply! This is only one of many examples where an amplifier can fail to meet specification.

In the real world most people like to fiddle. We have faulty hearing, acoustically poor rooms, irrational musical tastes, and a strong desire to keep up with the Joneses. Therefore, there's a market for tone controls, graphic equalisers, and other forms of post-production distortion. (Like turntablism!)

All good stuff, but I don't believe for one second it has anything to do with 'quality'. Selling people things they don't need is an art form too! But if the owner thinks a particular audio set-up sounds wonderful, he's right! Who am I to argue with his perception, even if the engineering is carp.

Dave

4 December 2019 at 14:57 #440214Joseph Noci 1

Participant@josephnoci1Me upset??? You need to try harder than that..Or just start a discussion of oxygen-free Copper speaker cables and their beneficial addition to the system's sound…

If pedantism rules, then I would agree with the cold interpretation of quality existing only if it is measurable. I have however seen products manufactured and passing muster under the manufacturers ISO9000 accreditation, only to fail miserably in the lack of 'good workmanship' – The ISO accreditation allows for many sins to be committed at the artisan level, as such systems often fail to dictate the criteria artisans apply in the daily application of their 'art'.

If a 12mm hole is required to be within plus/minus 2mm of a drill point, and the hole diameter may lie between 10.5 and 13.5mm, that does not mean the Worker should not measure where the hole should be, that he should not center-pop the point, or that he should grab blindfolded for the nearest size drill – failing to do any of these, just because the process allows him to, just breeds bad practice for future use.

Perhaps we mix good workmanship and quality up somewhat in means and definition thereof, but I do believe that anyone with self-pride, and an interest in how he does things, an interest in the product, etc, would plainly see the difference between good and poor workmanship. The observer might not notice that the product is also good or bad 'quality' – Quality is not visible, no matter how you may wish it was. The quality process only managed to ensure that the correct part number component was fitted in the correct hole, and the soldering iron was at the correct temperature when the legs were soldered, and the solder was the correct ( lead-free!) stuff. How well the artisan did the soldering job is up to the artisan, not the QA process…If the dry joint passes inspection, then the artisan failed..

Sometimes good workmanship gets in the way of profits – the old 'time is money' saga, so neatly dressing wires where its not needed, sanding smooth the angled-ground marks on the casting ( within sound limits..), etc, may be a waste of time, money, or whatever, but unless outlawed by the Boss, I believe it speaks to the mindset of the worker/artisan.

Attention to detail, cleanliness in application, neatness of work, none of which can be easily specified in a quality process, are all , in my opinion, essential elements in making a good worker, and a good product.

I'm not sure we have an addiction to quality as such – I think nostalgia is also a culprit in our thinking though.

When you want to purchase a jersey in the high street shop ( I'm lucky here, I have no high street… let alone shops..) you may rub the wool between your fingers ( while rubbing the shop assistant up the wrong way as well) -to judge the 'quality'

While wool quality is measured by strength, staple length, fineness and consistency ( among other things), you would not determine any of this while rubbing the jersey…however, if you 'rubbed' a Cashmere weave and then a jersey made from local 'farm' wool, you could be forgiven for thinking the Cashmere jersey is a far better quality. You may (probably) also be forgiven for thinking it's wool..it is in fact hair, from the Kashmir goat.

Measurable quality, I believe, is a phenomena that exist almost only in the engineers mind – the rest of the population have there own definitions! But workmanship can be seen and felt – which is what most of the 'better in the old days' nostalgia relies on for survival.

Back to the subject though –

I am not sure that we should lump 'Hi-Fidelity' listening in the same basket as the Stomp-boxes, combo amps, and general equipment as used by those rock and roll ruffians. Yes, Hi-Fi ( not that crap with 4liter speakers, a combined CDplayer, Tuner, 'amplifier, USB music player, all up 2 kg weight..) should be the piece of wire with gain.

But that is not what the Bands or gig players want. I would not want the amp to add unpredictable bad sounding distortion, or for it to 'modify' the sound in unpredictable fashion, at odd moments. However, each ego demands that the sound exiting the amp at the end if his guitar must be 'unique'; must sound 'good' to his ears, etc. So the amp must be able to be abused, trans-sounded, more slappy, etc. How would you describe the amps being 'brighter' in 'quality terms' ?? Sort of – the frequencies between 3khz and 4.795khz are boosted by 7.956dB, while the frequencies between 5Khz and 9Khz are raised 3,9dB and those below 2KHz are reduced by 4dB per decade….And the sound Mixer fellow will say …Huh??, you mean brighter??

My pennies worth..

J

4 December 2019 at 18:07 #440262 Neil WyattModerator@neilwyattPosted by SillyOldDuffer on 04/12/2019 11:16:25:

Neil WyattModerator@neilwyattPosted by SillyOldDuffer on 04/12/2019 11:16:25:As an engineering artefact, I suggest the perfect amplifier is one with zero distortion, that is the output waveform is identical to the input apart from being louder. An amplifier shouldn't sound 'cleaner', 'brighter', 'slappy', 'vintage', or add any other characteristic to the sound whatsoever.

Err.. that might be true of your hifi, but you could hardly be more wrong when it comes to guitar amplifiers… all those non-linearities, phase differences, power sags and distortion are exactly what give the differences between amplifiers that users both crave and argue about!

There's a world of difference between amplifiers meant for reproduction and those meant for performance, in the latter case the ability to colour and modify the sound is absolutely critical. Otherwise we would have to sit and listen to music "seraphically free from the taint of personality".

Example – power supply sag means that when a signal is large enough to cause distortion in the output stages, the distortion tends to drop more slowly as the sound drops in volume, rather than rapidly cleaning up as it fades.

The one exception – a modern trend is 'FRFR' amps and speakers (Full Range Flat Response) so that they can be fed with digital models of all those foibles and accurately reproduce a wide range of different amps – in fact some people now just use an emulation box and the PA with in-ear monitors.

And yes, several of these emulating amps have been discovered to sound much better when the tweeter is removed! And as I mentioned above, mine has a valve in it as digital simulation still doesn't cut the mustard.

Neil

4 December 2019 at 18:24 #440264Clive Hartland

Participant@clivehartland94829This takes me back to when I first heard stereo. I lived above a model shop and I got on well with the owner and he showed me and let me hear a stereo record, wow, the doppler effect of a train going past to me was amazing. This set me off on an Amplifier building session. The choice, a Mullard 5 x5 or a 10 x 10. So I made the 5 x 5 and made the chassis and managed to get all the parts to do it. Except the output Trafo. I eventually got it wound by a local lad and it was fine. One experience was connecting the speaker the wrong way and getting the , 'Motoboating' effect.

A while later I was in Kenya and we had a few records but I wanted to listen to specific radio staions and having an LCR meter/bridge at work. (Querey that) I made a fixed frequency diode and capacitor and a resistor for BBC world service. It worked fine so I made others for odd staions and at various times of day could hear the US or South Africa, also the local FBS station. sadly I am now almost deaf and cannot hear music nor telephone voice, the TV is like jungle noises, thank heavens for text.

4 December 2019 at 18:42 #440266 Mike PooleParticipant@mikepoole82104

Mike PooleParticipant@mikepoole82104The holy grail for a musician is to have their own sound, some will freely describe how they achieve it and others will guard their secret. Some like a clean sound like Hank Marvin and others will have a huge pedal board and all sorts of effects even before the amp adds its two pence worth.

Mike

4 December 2019 at 19:12 #4402724 December 2019 at 19:30 #4402754 December 2019 at 19:35 #440277 Mike PooleParticipant@mikepoole82104

Mike PooleParticipant@mikepoole82104I was at a local blues jam which I used to go to regularly, just to listen as I can’t play a note on anything. The lineup changed round after every couple of songs so I was nattering to a mate as they started playing, instantly I knew the bass had changed and that it was Dominic Telfer who I had seen a few times before. It always amazes me how good the local musicians are, most have never been famous and never will be but can match anyone who did get the lucky breaks.

Mike4 December 2019 at 20:08 #440281mark smith 20

Participant@marksmith20Yes theres certainly alot of talented musicians around who never get a break.

A friend of mine made it big, turned him into a ass. L.A, Drugs etc… But he eventually came down to earth . (Frank Dunnery of Its Bites etc..) Great musician but his older brother was better, he never wanted fame and despite offers from all over the place and refusing to fly ended up never leaving the village.

Another friend did quite well , he married that lady out of Bucks Fizz

He currently plays with Rick Wakeman.

He currently plays with Rick Wakeman.I know several local guitarists who are very good but never really got a break.Also drummers. Great to listen to in pubs etc.. and can take their hands to any styles of music.

Edited By mark smith 20 on 04/12/2019 20:09:04

4 December 2019 at 20:30 #440287 Neil WyattModerator@neilwyattPosted by Mike Poole on 04/12/2019 19:35:48:

Neil WyattModerator@neilwyattPosted by Mike Poole on 04/12/2019 19:35:48:I was at a local blues jam which I used to go to regularly, just to listen as I can’t play a note on anything. The lineup changed round after every couple of songs so I was nattering to a mate as they started playing, instantly I knew the bass had changed and that it was Dominic Telfer who I had seen a few times before. It always amazes me how good the local musicians are, most have never been famous and never will be but can match anyone who did get the lucky breaks.

MikeIt's fascinating when you hear a song you've never heard before but recognise the guitarist, vocalist or just the band as a whole – I did it last night with an REO Speedwagon song on the radio. Equally interesting when you get it wrong – it's usually easy to spot a song produced by Jeff Lynne but I was fooled by So Tired by Ozzy Osborne which wasn't!

5 December 2019 at 00:30 #440310 Mike PooleParticipant@mikepoole82104

Mike PooleParticipant@mikepoole82104I played a cassette I had recorded years ago of Coloseum ll I thought the guitar sounded like Gary Moore, it turned out is was but I suppose he is quite distinctive.

Mike

5 December 2019 at 06:59 #440319Geoff Theasby

Participant@geofftheasbyMention of my favourite guitarist got my attention. I have probably every one of the Shadows recordings, and regard him as unique. However, I have recently discovered Albert Lee, and wonder why it took me so long. Anyway, these last two postings made me think about the varying sounds to be obtained from ostensibly the same guitar. Albert Lee often plays a Fender Telecaster, yet makes it sound completely different from any other player. The same company's Stratocaster has a recognisable 'clanky' sound, in the hands of many.

5 December 2019 at 11:15 #440347SillyOldDuffer

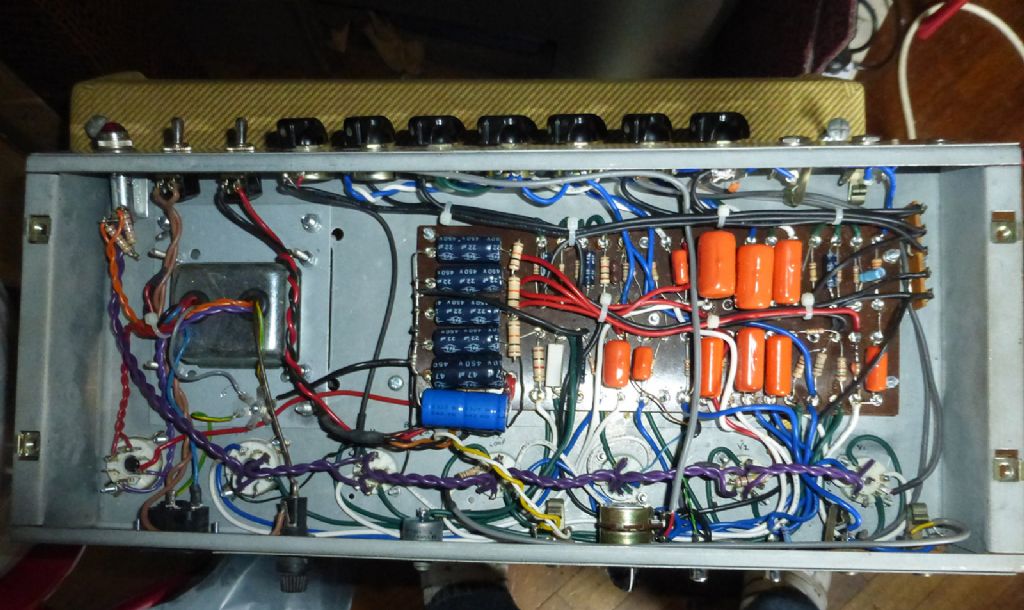

Moderator@sillyolddufferNice example of a real amplifier with a mix of best-practice and compromises!

Good news:

- The output valve is positioned next to the PSU and, being a power output stage, is relatively immune to picking up hum from the mains transformer.

- Laying out the valves with the hot power supply and output stage well away from the input stages is good practice – less heat.

- The transformers are angled on the chassis to discourage mutual coupling and are shielded from most of the sensitive wiring by the chassis.

- The rectifier valve is a double diode producing 100Hz half-cycles. 100Hz is easier to smooth than 50Hz.

- One of those transformers may be a power supply choke, which is good, but its size means it's a only a 'swinging choke'. These work well at low currents but their inductance and ability to filter drops when the power supply is heavily loaded. They cause distortion at full volume, where it's less likely to be noticed, the first compromise! Chokes that don't swing are heavy and expensive.

- The heater wires are tightly twisted to reduce radiation.

- The output valve is a 6V6 Beam Tetrode. Invented in 1936 the beam improves the valve's characteristic curves for low frequency applications – it distorts less than triodes, tetrodes, and pentodes. Impressive, I think, that 6V6's are still valued today.

Compromises:

- Most of the components are laid out on a tag board. This is easy to maintain, but increases the length of the wiring, which introduces a shoal of negative effects. High-end frequency response is reduced, there's more chance of hum pick-up and cross-talk, and a risk of parasitic oscillation. However, as audio amplifiers are low-frequency devices the impact on frequency response is trivial, and accidental pickup may be unnoticeable.

- Valves (and semiconductors) produce more power and less distortion in push-pull configuration. Unfortunately push-pull is more expensive and complicated. This amp has a single 6V6. It's good but it can't be very good!

- Two of the ECC83's (also good audio valves, circa 1945) are 'Made in Russia'. When transistors removed the mass-market for vacuum tubes, people stopped making ECC83s in the West. Russia produced valves for rather longer, but doubt was cast on their quality. I've no idea if modern Russian valves are inferior to older Western-made valves or not. Audiophiles say they can tell the difference.

- Perhaps the most serious compromise is the way the amp is mounted upside-down in the cabinet. A disadvantage of valves is they run hot, each containing an electric heater burning a couple of watts each, or more. This is before power is applied to do anything useful. Usually valves are mounted on top and ventilated to convect the heat away. Being valves down, this one dumps heat into the chassis, and, adding to the problem, the amp is positioned at the hottest part of the speaker cabinet. This may be why the aluminium shielding cans are missing. Ideally present to keep stray fields out of the valve, they keep heat in too! On average shielded valves don't last as long in service as unshielded valves.

It's possible to pick almost any technical solution apart in this way. Actually, I think Marks' amp is a thoroughly acceptable compromise. I've not spotted anything careless or ill-considered, and it should do a good job. But it's not the end of the story, nor is Joes' Mesa. If a designer were called on to build an amplifier linear at 10MHz, most of the construction style used in Mark's amp is asking for trouble, and at 30MHz it's unacceptable. The need to do better than needed in audio amps has pushed electronics into entirely different technologies: 5G runs at 26GHz.

Returning to my theme about the psychology of technology, I find it interesting that people have strong opinions about low-tech stuff like hi-fi amplifiers, hand-tools and manual lathes, but have nothing to say about high-tech products. I suppose when ordinary domestic gizmos like mobile phones are beyond the understanding of any individual, all you can do is criticise their colour, size, lack of signal, battery life, instructions (in 17 languages) and useless support service! Modern technology is a right spoil-sport.

Dave

Edited By SillyOldDuffer on 05/12/2019 11:23:46

5 December 2019 at 12:06 #440355mark smith 20

Participant@marksmith20Hi Dave, you obviously know alot more than me about amp circuits etc.. The valves do have cans on them by the way but the amp cabinet is open backed, so i havent noticed any heat problems. It has a strip of wood to stop the valves getting knocked though.

These amps were designed by Barry Vyse and mine was probably built in kit form on one of his amp building courses. Hes a very knowledgable guy and worked for Marconi Osram i believe. Wrote a book on the subject.

Do you happen to know which is the cathode bias resistor in the photo of the inside ??

Thanks Mark

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Latest Replies

Home › Forums › The Tea Room › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Smart & Brown Model L lathe help required

Started by:

AJAX in: Manual machine tools

- 1

- 3

-

23 August 2025 at 21:14

AJAX

-

Blackgates 3 Way Toolpost Casting

Started by:

John McCulla in: Materials

- 11

- 16

-

23 August 2025 at 21:08

Pete

-

THE MAUDSLAY TABELE ENGINE

Started by:

sivtek1 in: Introduce Yourself – New members start here!

- 1

- 1

-

23 August 2025 at 21:01

sivtek1

-

A4 stainless

Started by:

David Ambrose in: Materials

- 11

- 15

-

23 August 2025 at 20:05

Martin Kyte

-

Phone Phreaking

Started by:

Michael Gilligan

in: Clocks and Scientific Instruments

Michael Gilligan

in: Clocks and Scientific Instruments

- 11

- 13

-

23 August 2025 at 20:04

Marcus Bowman

-

QCTP for chester lathe

Started by:

Chris12 in: Beginners questions

- 11

- 25

-

23 August 2025 at 17:36

dk0

-

This weeks oddity!

Started by:

Martin King 2 in: Help and Assistance! (Offered or Wanted)

- 4

- 5

-

23 August 2025 at 17:29

Martin King 2

-

Asong power feed?

Started by:

Hollowpoint in: General Questions

- 5

- 6

-

23 August 2025 at 16:55

Stuart Smith 5

-

New member, progress no.1 rest

Started by:

flyingsailor in: Introduce Yourself – New members start here!

- 5

- 7

-

23 August 2025 at 16:11

flyingsailor

-

My week this week! My workshop videos

1

2

…

11

12

Started by:

Phil Whitley in: The Tea Room

- 16

- 297

-

23 August 2025 at 16:05

Phil Whitley

-

Material advice

Started by:

tobyonekenobi in: Materials

- 9

- 18

-

23 August 2025 at 11:19

Martin Connelly

Martin Connelly

-

Yet another scam

Started by:

Dell

in: The Tea Room

Dell

in: The Tea Room

- 9

- 13

-

23 August 2025 at 11:08

Howard Lewis

-

Taylor Hobson cutter grinder modificaton

1

2

Started by:

David George 1

in: Workshop Tools and Tooling

David George 1

in: Workshop Tools and Tooling

- 9

- 39

-

23 August 2025 at 08:43

Andrew Crow

-

Museum donation

Started by:

Stephen Wessel 1 in: Introduce Yourself – New members start here!

- 2

- 2

-

22 August 2025 at 20:36

Bazyle

Bazyle

-

Casting – off center hole correction

Started by:

colin hamilton in: Workshop Techniques

- 9

- 10

-

22 August 2025 at 17:38

colin hamilton

-

Granville lathe leadscrew change wheel

Started by:

JACK SIDEBOTHAM in: Help and Assistance! (Offered or Wanted)

- 10

- 17

-

22 August 2025 at 17:07

Howard Lewis

-

wood working

Started by:

Danni Burns in: Beginners questions

- 9

- 12

-

22 August 2025 at 15:55

Danni Burns

-

3″ Castings – Help/Advice needed

Started by:

Andy Porter 1 in: Traction engines

- 4

- 6

-

22 August 2025 at 13:15

JasonB

JasonB

-

AI ads

Started by:

Ian Parkin in: The Tea Room

- 5

- 5

-

22 August 2025 at 13:00

jimmy b

jimmy b

-

1″ Minnie Traction Engine

Started by:

milburyring@btinternet.com in: Traction engines

- 3

- 8

-

22 August 2025 at 08:53

milburyring@btinternet.com

-

Solar panel

Started by:

duncan webster 1 in: Electronics in the Workshop

- 8

- 13

-

22 August 2025 at 07:19

Michael Gilligan

Michael Gilligan

-

The stand alone weight for tower clock

1

2

Started by:

dk0 in: Clocks and Scientific Instruments

- 12

- 36

-

21 August 2025 at 23:59

Clive Steer

-

Install & commission of a Chester Cub 630 (Warco GH750)

1

2

3

Started by:

Calum in: Manual machine tools

- 22

- 74

-

21 August 2025 at 21:52

noel shelley

-

Softening epoxy

Started by:

John Haine in: General Questions

- 17

- 25

-

21 August 2025 at 18:57

Martin Dilly 2

-

What Did You Do Today 2025

1

2

…

9

10

Started by:

JasonB

in: The Tea Room

JasonB

in: The Tea Room

- 35

- 226

-

21 August 2025 at 17:38

Dalboy

-

Smart & Brown Model L lathe help required

-