In my limited, recent experience I would say yours looks fine. The 4mm gap I saw was the distance that the carriage had been pulled off the shaft, shearing the taper pin in the upper bevel gear in the process. There can't have been much shaft still within the bevel gear actually, although it still worked as the mechanism was turned by hand. The gap was the only indication that anything was actually wrong.

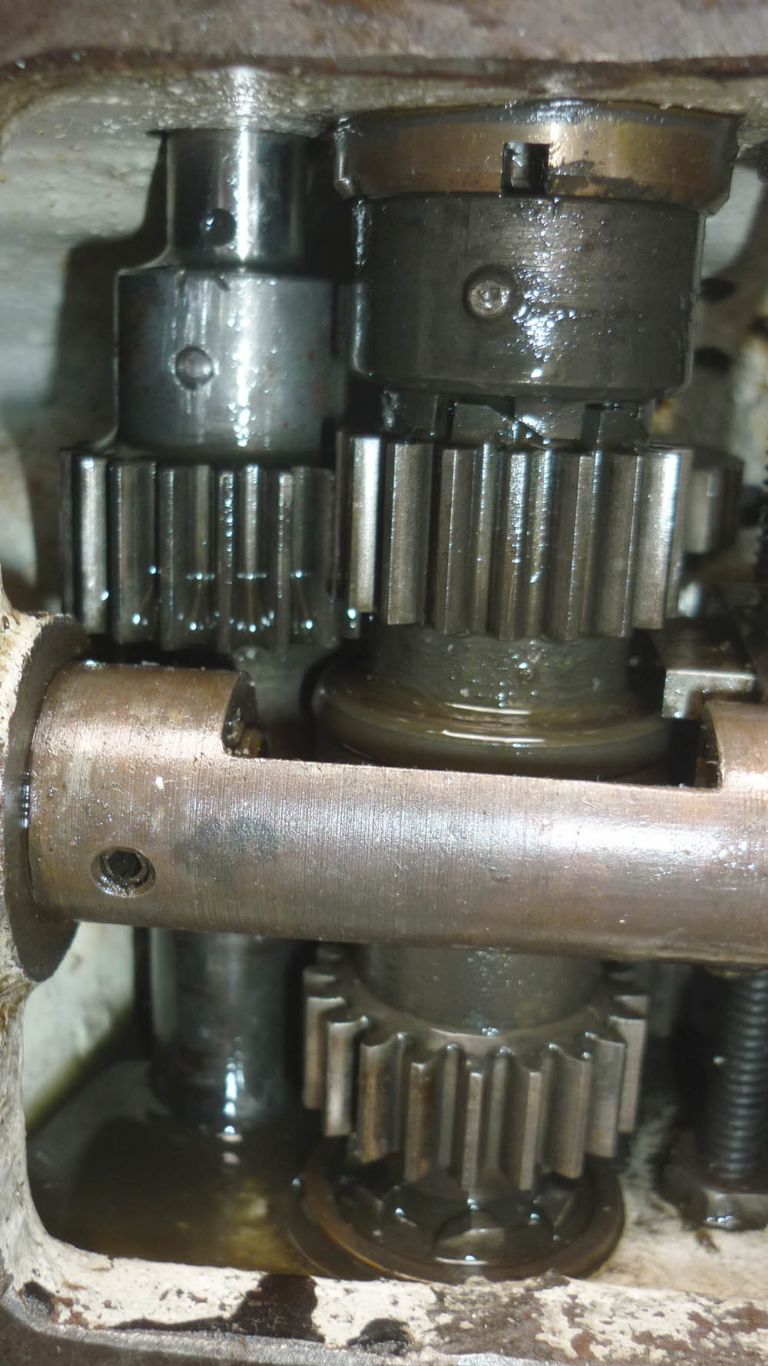

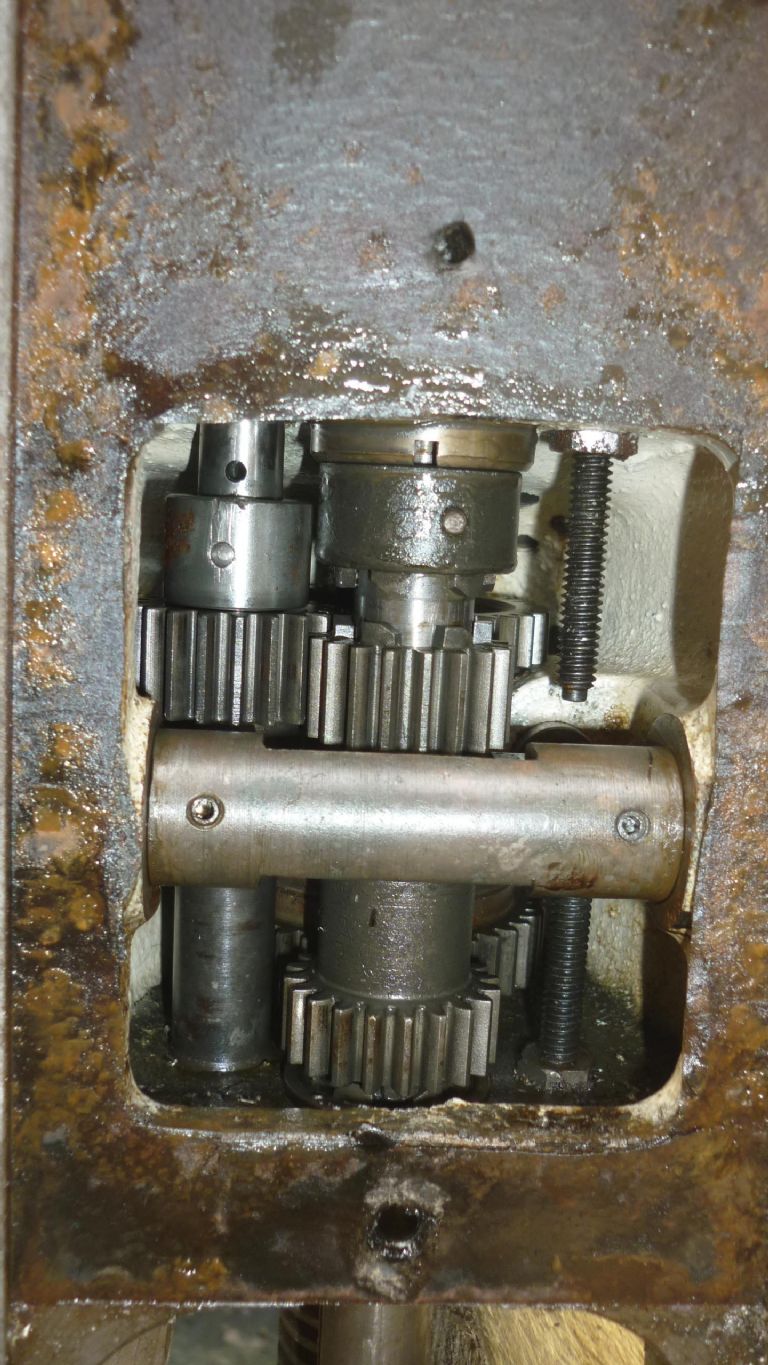

Normally the distance between the upper dog clutch and the upper bevel gear is fixed by both parts being located on the shaft by taper pins. In fact that is the only vertical location provided for the shaft, everything else being keyed to slide up and down it. There is a thick washer under the upper bevel gear, which may possibly be some kind of selective assembly fit as there are no other shims or packers in the system to eliminate any up and down movement. My guess would be that the thick washer maintains the optimum clearance between the upper bevel gear and the upper dog clutch to the bearing tube that sits between those two parts and sits slightly proud of the casting as it emerges top and bottom. The correct setting of the upper bevel gear into the two crown wheels within which it runs is then achieved by moving this bearing tube within the machine casting. Once set this tube is fixed in place by a pair of grub screws. The diagram posted by Phil P illustrates this relationship pretty well – although it only shows one grub screw holding what may even be a two part bearing tube in the Deckel machine whereas my machine has an upper and lower grub screw. .

To me it looks like the whole thing is designed to run for a long time without being messed about with – unless of course the machine is left outside for several years and bits get stuck together with rust causing a taper pin to shear!

Jerry Bland 1.